Carbon Fiber Hoods: Your Ultimate Guide to Performance, Aesthetics, and Value

This comprehensive guide explores the world of carbon fiber hoods, detailing their impact on automotive performance and aesthetics. We break down the differences between carbon fiber and fiberglass, highlight key benefits like weight reduction and durability, and discuss potential drawbacks. Whether you are a tuner looking for speed or an enthusiast seeking style, this article provides essential tips on selection, installation, and maintenance to help you make an informed upgrade for your vehicle.

- Introduction: Why Carbon Fiber Hoods Are Redefining Automotive Style and Performance

- What Exactly is a Carbon Fiber Hood?

- Unlocking the Benefits: Why Upgrade to a Carbon Fiber Hood?

- Carbon Fiber Hood vs. Fiberglass Hood: A Head-to-Head Comparison

- Potential Drawbacks & Important Considerations for Carbon Fiber Hoods

- Choosing the Right Carbon Fiber Hood for Your Vehicle

- Installation & Maintenance Tips for Maximizing Longevity of Your Carbon Fiber Hood

- Conclusion: Is a Carbon Fiber Hood the Right Upgrade for You?

- Frequently Asked Questions

- What is the primary benefit of a carbon fiber hood for a car?

- Are carbon fiber hoods durable for daily driving?

- Can I paint my carbon fiber hood?

- How do I prevent my carbon fiber hood from yellowing?

- Are carbon fiber hoods worth the extra cost over fiberglass or OEM?

- Do I need hood pins with a carbon fiber hood?

- How much does a carbon fiber hood typically cost?

- What's the process for installing a carbon fiber hood?

Introduction: Why Carbon Fiber Hoods Are Redefining Automotive Style and Performance

In the world of automotive enthusiasts, no single modification promises performance and style like a carbon fiber hood. Once the exclusive domain of million-dollar hypercars and professional race teams, carbon fiber technology has now found its way into the aftermarket, where it has become a standard component among tuners, racers, and car show veterans. So why is this special woven substance the subject of obsession?

The answer lies in the quest for perfection. Engineers and enthusiasts in the automotive industry are constantly trying to overcome the laws of physics and find ways to reduce weight without compromising structural integrity. In the automotive industry, carbon fiber is the epitome of this balance; its strength-to-weight ratio is unmatched by traditional steel.

Replacing the hood with carbon fiber is not merely a cosmetic option; it is functional and can change how you drive your car. Whether you prefer the sleek look of a woven pattern or the practical advantages of a lightweight hood upgrade, this guide will be your last resort. We will delve into the manufacturing process, the advantages and disadvantages, the peculiarities of installation, and most importantly, the maintenance needed to keep your hood showroom-clean for years to come.

What Exactly is a Carbon Fiber Hood?

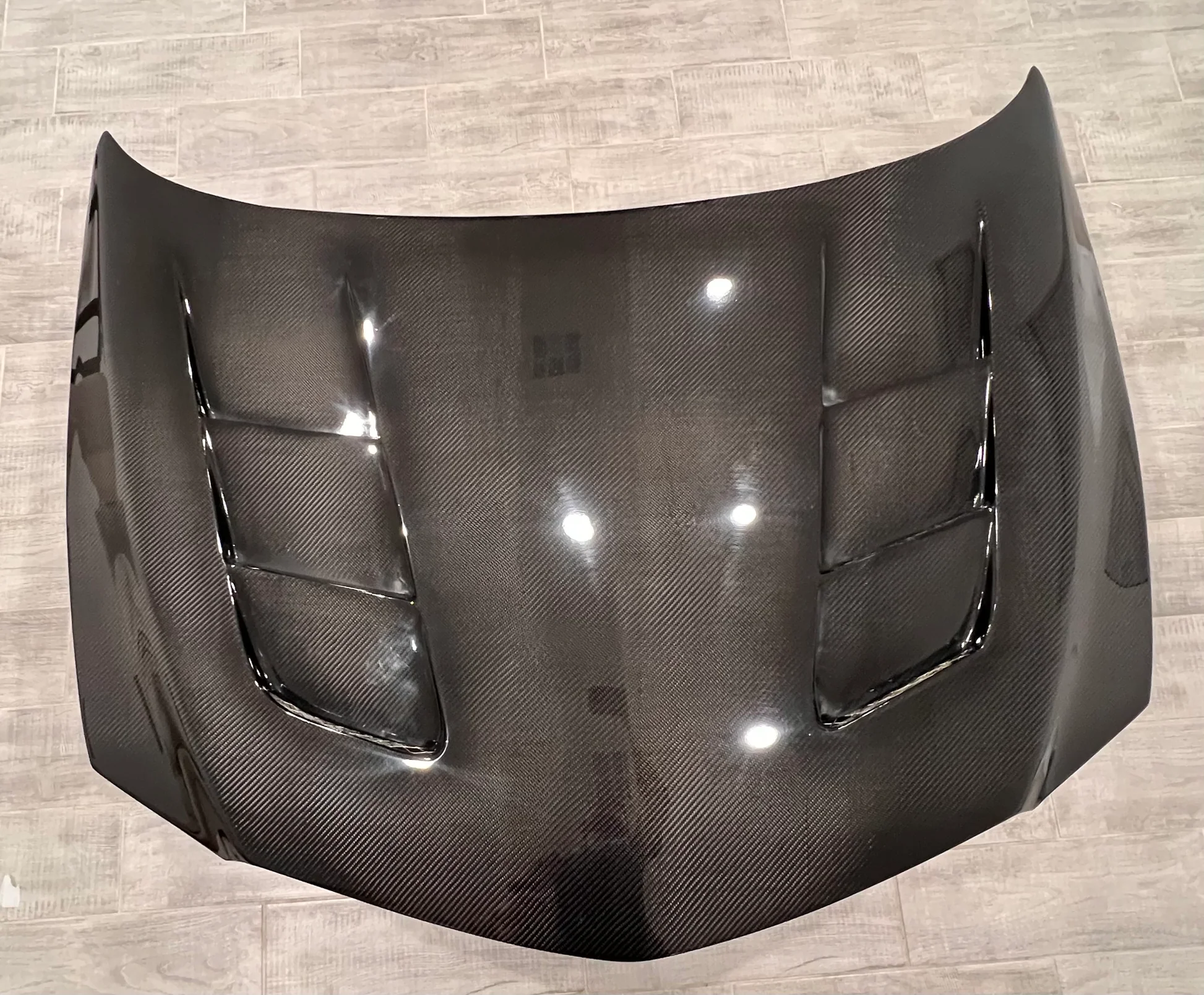

In order to understand the value proposition, it is first necessary to understand the material itself. Carbon fiber is a composite material consisting of thin, strong, crystalline filaments of carbon used to reinforce other materials. In the context of automotive parts, the filaments are woven into a fabric that is laid into a mold and infused with a binding polymer, usually epoxy resin.

The magic happens during the curing process. Through vacuum bagging or autoclave curing (a process involving high heat and pressure), the resin hardens and locks the woven fibers into an ultra-lightweight, rigid structure.

When shopping for custom carbon fiber parts, you will often encounter two distinct types of construction:

- Full Carbon Fiber (Dry Carbon): This involves pre-impregnated fibers cured in an autoclave. It is the lightest and strongest option, typically used in high-end motorsports. It has a matte finish unless clear-coated.

- Carbon-Skinned Fiberglass (Wet Carbon): This is the most common type found in the aftermarket. It features a core layer of fiberglass for structure, wrapped in a top layer of carbon fiber for the aesthetic weave. While slightly heavier than dry carbon, it is still significantly lighter than steel and offers the iconic glossy look at a more accessible price point.

-

Unlocking the Benefits: Why Upgrade to a Carbon Fiber Hood?

Is a carbon fiber hood just for show, or does it offer real advantages? The answer to both is a resounding yes. This is why the advantages of a carbon fiber hood are a hot topic among performance drivers.

Considerable weight loss

The most immediate functional advantage is reduced weight. An OEM steel hood may weigh between 30 and 60 pounds, depending on the car. A high-quality carbon fiber replacement weighs only between 10 and 20 pounds. Losing 20–50+ pounds at the front of the car improves the power-to-weight ratio because the engine doesn't have to work as hard to propel the car forward.

Improved performance and handling

Weight loss affects not only straight-line speed but also balance. Eliminating heavy steel from the front end moves the center of gravity back and reduces the vehicle's moment of inertia. This results in a sharper turn-in response, less understeer, and better handling dynamics. Additionally, the less mass, the less work your brakes have to do, which may shorten stopping distances.

High-quality strength and durability

Carbon fiber is very stiff yet lightweight. It has high tensile strength, meaning it does not stretch or deform under load. Unlike steel, a carbon fiber hood will never rust, making it a lasting upgrade if it is well maintained.

Striking Aesthetics

Its visual impact is undeniable. The interlocking weave pattern gives the hood a 3D depth that cannot be reproduced by paint. The high-gloss finish of the carbon fiber hood indicates to the world that the car is modified and performance-oriented. The rough, high-end feel distinguishes a custom car from a stock one.

Better Cooling and Aerodynamics

Most aftermarket best carbon fiber hoods are made with functional vents, scoops or louvers. These are not merely to look at; they assist in removing hot air in the engine bay, which decreases the intake temperatures and minimizes the hood lift (air pressure accumulating under the hood when traveling at high speeds).

Carbon Fiber Hood vs. Fiberglass Hood: A Head-to-Head Comparison

When looking for a lightweight hood upgrade, fiberglass is the primary competitor to carbon fiber. Here is how the carbon fiber vs fiberglass hood battle breaks down:

- Weight: Both are lighter than steel, but carbon fiber takes the crown. A fiberglass hood is light, but a dry carbon hood is featherweight. For maximum performance gains, carbon fiber is the winner.

- Strength & Rigidity: Fiberglass is somewhat flexible and can crack under stress. Carbon fiber is significantly stiffer and structurally sounder, offering better longevity under high-performance conditions.

- Cost: This is where fiberglass wins. Fiberglass hoods are generally much cheaper to manufacture and purchase. Carbon fiber requires complex manufacturing and expensive raw materials, leading to a higher price tag.

- Durability & Repairability: While carbon fiber is stronger, it is difficult to repair if the weave is damaged. Fiberglass, while more prone to cracking, can be easily patched, sanded, and repainted by any body shop.

- Aesthetics: Fiberglass usually comes in a gel coat meant to be painted. Carbon fiber is chosen specifically for its exposed weave. If you plan to paint the hood to match the car perfectly, fiberglass might be the more improved budget choice. If you want the raw look, carbon fiber is the only option.

Verdict: Choose carbon fiber for performance, rigidity, and the premium exposed-weave look. Choose fiberglass for budget-friendly customization where the part will be painted anyway.

Potential Drawbacks & Important Considerations for Carbon Fiber Hoods

To provide a balanced view, we must look at the carbon fiber hood pros and cons. It is not always a perfect solution for every car owner.

- Higher Upfront Cost: As mentioned, quality comes at a price. A legitimate carbon fiber hood is a significant financial commitment compared to other cosmetic mods.

- Repair Difficulty: If you are in a front-end collision or a heavy object falls on the hood, the carbon weave can fracture. Unlike metal which can be hammered out, or fiberglass which can be patched, damaged carbon fiber usually requires full replacement to restore the aesthetic look.

- UV Degradation: The epoxy resin used in carbon fiber is sensitive to UV rays. Without proper care, it can oxidize, turning the clear coat cloudy, yellow, or milky over time.

- Fitment Variation: While OEM hoods are stamped by robots for millimeter-perfect precision, aftermarket composite parts are often hand-laid. This can lead to panel gaps that are slightly uneven. Adjustments to fenders, hinges, or the latch mechanism are often required.

- Painting Challenges: If you decide to paint a carbon fiber hood, prep work is extensive. The surface must be meticulously sanded, and specialized primers or flex agents are often needed to prevent the paint from cracking as the hood flexes and heats up.

Choosing the Right Carbon Fiber Hood for Your Vehicle

Navigating the market for best carbon fiber hoods requires attention to detail.

- Vehicle Specificity: Never assume a hood fits multiple model years. Facelifts often change headlight shapes and grill alignments. strict compatibility checks are essential.

- Quality of Construction: Research the weave. A consistent "2x2 Twill Weave" is the industry standard for that classic diagonal look. Cheaper hoods may have "waves" or distortions in the pattern. Inspect photos for a smooth, glass-like resin finish without pits or bubbles.

- Style & Function: Do you want a sleeper look? Go for an OEM-style replacement. taking the car to track days? Look for aggressive vents that align with your radiator or intercooler setup.

- Brand Reputation: Stick to established brands in the aftermarket community. Read forums and reviews regarding fitment. Brands like Supreem Carbon that specialize in custom carbon fiber parts generally have better quality control than generic eBay sellers.

Installation & Maintenance Tips for Maximizing Longevity of Your Carbon Fiber Hood

After buying your hood, the work isn't over. Proper installation and care of your carbon fiber hood are critical.

Professional installation is recommended

Although it may seem like a simple bolt-on, hood alignment is an art form. Professional body shops can alter the fenders and hinges to make the gap even. They can also relocate the windshield washer nozzles and heat shielding properly.

The Importance of Hood Pins

This is a critical safety feature. Carbon fiber hoods are light. At highway speeds, air pressure on the hood may increase when it enters the engine bay. Since the stock latch is designed for a heavy steel hood, the lightweight composite structure may become flexible, or the latch may give way when lifted, resulting in the hood flying off. Hood pins provide a mechanical lock between the hood and the radiator support, which helps prevent windshield damage.

Regular cleaning

Treat your hood as you would the paint on your car. Clean it frequently with mild automotive soap and a soft microfiber mitt. Never use an automatic car wash with rough brushes, as they can scratch the clear coat.

UV Protection is Mandatory

The sun is the enemy of carbon fiber resin. To prevent yellowing, you must apply a layer of protection.

- Wax/Sealant: Apply a high-quality carnauba wax or synthetic sealant every few months.

- Ceramic Coating: For the best protection, apply a ceramic coating. This bonds to the surface, providing a hard layer of UV resistance that lasts for years.

- Clear Coat: If you buy a cheaper hood, consider having a body shop spray it with a high-solids automotive clear coat with UV inhibitors immediately after purchase.

Conclusion: Is a Carbon Fiber Hood the Right Upgrade for You?

A carbon fiber hood is more than just a flashy accessory—it's a statement of intent. It signifies dedication to performance through weight reduction and appreciation for high-tech materials. The benefits regarding handling, acceleration, and visual appeal are undeniable. However, these benefits come with higher costs, specific maintenance needs, and the need for careful installation.

If you're building a track car, a show car, or simply want to improve your daily driver's agility, a carbon fiber hood is a premium investment that pays dividends in both form and function. Weighing the pros and cons outlined in this guide will help you confidently choose the perfect hood to elevate your vehicle's build.

Frequently Asked Questions

What is the primary benefit of a carbon fiber hood for a car?

The primary benefit is significant weight reduction, which improves a car's power-to-weight ratio, leading to better acceleration, handling, and braking, along with a distinct high-performance look.

Are carbon fiber hoods durable for daily driving?

Yes, high-quality carbon fiber hoods are very durable. They are resistant to fatigue and impact, making them suitable for daily driving, provided they are properly installed and maintained.

Can I paint my carbon fiber hood?

Yes, carbon fiber hoods can be painted, but it requires careful preparation and a specific clear coat to ensure proper adhesion and a durable finish. Many owners choose to leave the carbon fiber exposed for its unique aesthetic.

How do I prevent my carbon fiber hood from yellowing?

To prevent yellowing, ensure your carbon fiber hood has a high-quality UV-resistant clear coat from the manufacturer. Additionally, regularly apply UV-protective waxes, sealants, or ceramic coatings, and store the vehicle out of direct sunlight when possible.

Are carbon fiber hoods worth the extra cost over fiberglass or OEM?

For performance enthusiasts seeking maximum weight savings, enhanced vehicle dynamics, and a premium aesthetic, carbon fiber hoods are often considered a worthwhile investment despite their higher cost compared to fiberglass or OEM steel hoods.

Do I need hood pins with a carbon fiber hood?

While not always strictly required for all aftermarket carbon fiber hoods, hood pins are highly recommended, especially for performance applications or high-speed driving, to provide an extra layer of security against accidental hood lift.

How much does a carbon fiber hood typically cost?

The cost of a carbon fiber hood can vary widely depending on the vehicle model, manufacturer, and construction quality, typically ranging from $500 to over $2000.

What's the process for installing a carbon fiber hood?

Installation generally involves removing the old hood, transferring hinges and latches (or installing new ones), carefully aligning the carbon fiber hood, and securing it. Professional installation is highly recommended to ensure proper fitment, safety, and alignment.

New Arrivals of BMW S1000RR 2020+ full carbon fiber sets.

Supreem Carbon new engine cover released!

New Motorcycle Carbon Fiber Parts released!

Rev Up Your Ride: Supreem Carbon - China's Finest Custom Motorcycle Carbon Fiber Parts

Unveiling Carbon Fiber: 10 Surprising Truths and How It's Shaping Our Future

Upgrade Your Ride: Custom Motorcycle Carbon Fiber Parts by Supreem Carbon

For Products

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

BMW S1000RR S1000R Carbon Fiber Front Fender

The Supreem Carbon Front Fender for BMW S1000RR and S1000R is engineered for durability, precision fitment, and high-performance applications. Manufactured using premium-grade carbon fiber, this fender provides exceptional rigidity, reduced weight, and enhanced aerodynamics—making it suitable for performance upgrades, aftermarket tuning, and professional customization projects.

Lamborghini Urus Carbon Fiber Engine Bay Panel

Enhance the visual appearance of your Urus engine bay with these custom carbon fiber engine covers. 100% handmade and a 1:1 copy of the original part, which retains all OEM screw mounting points. Elevate your driving experience with this exquisite addition, showcasing unparalleled craftsmanship and enhancing the allure of your Urus’s engine bay.

Yamaha R1 R1M Carbon Fiber Undertail

Kawasaki H2 Carbon Fiber Front Fairing

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram