Prepreg Carbon Fiber: The Definitive Guide to Advanced Composite Performance

Prepreg carbon fiber is the pinnacle of composite materials, offering unmatched strength-to-weight ratios and precision. This guide explores what prepreg is, how it differs from wet layup, and why major industries like aerospace and automotive rely on it. Read on to learn about the different types of prepreg, the critical role of resin content, and future innovations in thermoplastic recyclability that are shaping the next generation of advanced engineering.

- Introduction: The Dawn of High-Performance Composites

- What Exactly is Prepreg Carbon Fiber?

- The Unmatched Advantages and Benefits of Prepreg Carbon Fiber

- Precision and Consistency

- Superior Mechanical Performance

- Cleaner and Safer Processing

- Exploring the Diverse Types of Prepreg Carbon Fiber

- Fiber Architecture

- Resin Systems: Thermoset vs. Thermoplastic

- Curing Requirements

- Key Applications: Where Prepreg Carbon Fiber Excels

- Aerospace and Defense

- Automotive and Motorsports

- Sports and Industrial

- Choosing the Right Prepreg Carbon Fiber for Your Project

- Future Trends and Innovations in Prepreg Technology

- Conclusion

- FAQs

- What is the primary difference between prepreg carbon fiber and traditional wet layup?

- Why is prepreg carbon fiber often more expensive than other composite materials?

- How should prepreg carbon fiber be stored?

- What curing methods are commonly used for prepreg carbon fiber?

- Can prepreg carbon fiber be used for DIY or hobbyist projects?

- What are the main types of weave patterns available for prepreg carbon fiber?

- Is prepreg carbon fiber recyclable?

- How does resin content affect prepreg performance and processing?

Introduction: The Dawn of High-Performance Composites

The contemporary engineering environment is motivated by one thing, and that thing is the desire to have as much strength as possible and as little weight as possible. The need to have materials which break the performance boundaries of conventional materials has never been more than it is in the fuselage of the next generation aircrafts and the chassis of the electric super cars. Prepreg carbon fiber is at the head of this revolution.

In comparison to the conventional composite techniques that imply the use of manual resin, prepreg is a step forward in the creation of precision and material reliability. It is the material that engineers who are unable to compromise use. IMARC Group reports that the global carbon fiber prepreg market was estimated to be worth about 11.3 billion in 2024, which is an indication that the market is important in the manufacturing industry. This guide will take you through all that you should know about prepreg carbon fiber; its technical definition and high properties, its practical use and its selection criteria.

What Exactly is Prepreg Carbon Fiber?

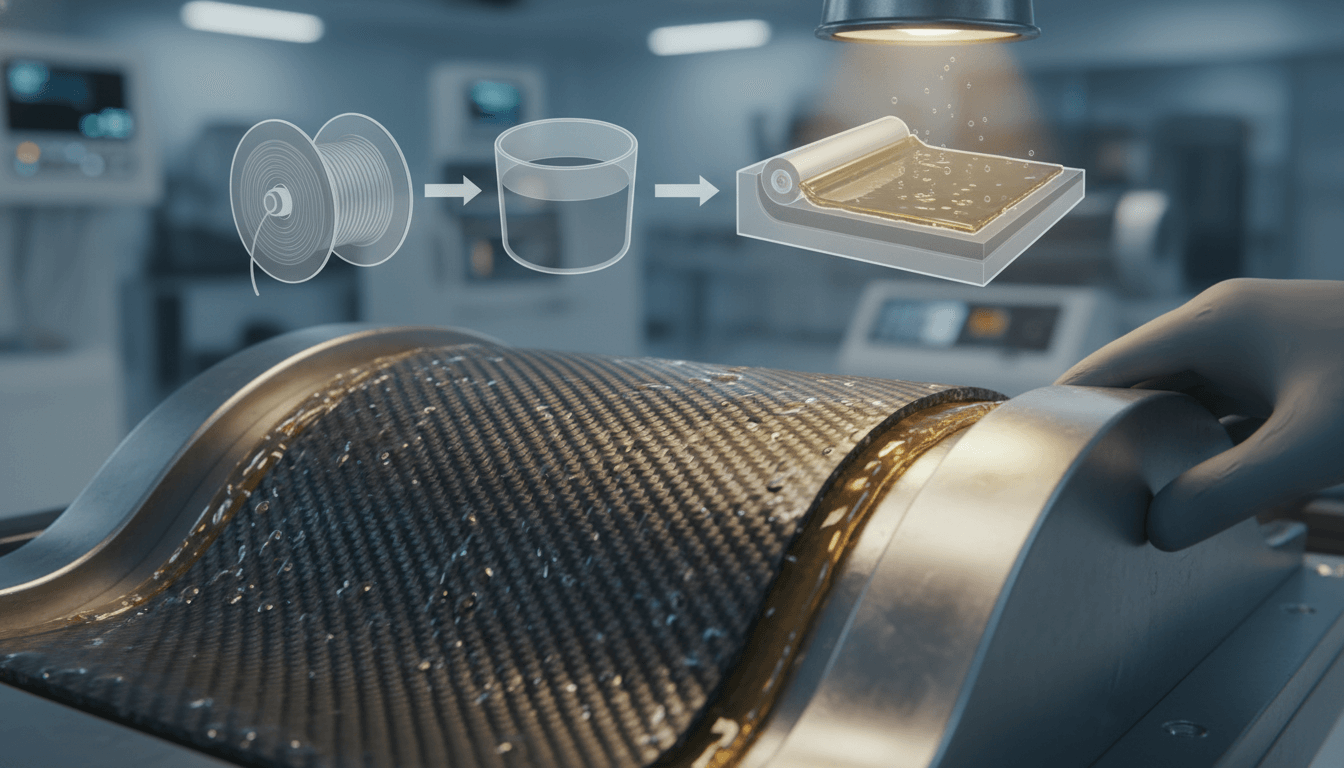

The term "prepreg" is a portmanteau of "pre-impregnated." In technical terms, it refers to a reinforcement fabric—typically carbon fiber—that has been pre-impregnated with a resin system, usually epoxy, by a manufacturer under strictly controlled conditions.

Unlike "dry" carbon fiber, which requires the user to mix and apply liquid resin manually (a process known as wet layup), prepreg arrives ready to mold. The resin is already present in the perfect ratio, but it is in a semi-cured or "B-stage" state. To prevent the resin from curing prematurely, the material is kept frozen, typically at temperatures around -18°C (0°F).

When the material is ready to be used, it is thawed, cut, and placed into a mold. The final curing process—usually involving heat and pressure—activates the resin, consolidating the layers into a solid, high-performance part.

The Unmatched Advantages and Benefits of Prepreg Carbon Fiber

Why do industries willing to pay a premium choose prepreg over cheaper wet layup methods? The answer lies in consistency and mechanical performance.

Precision and Consistency

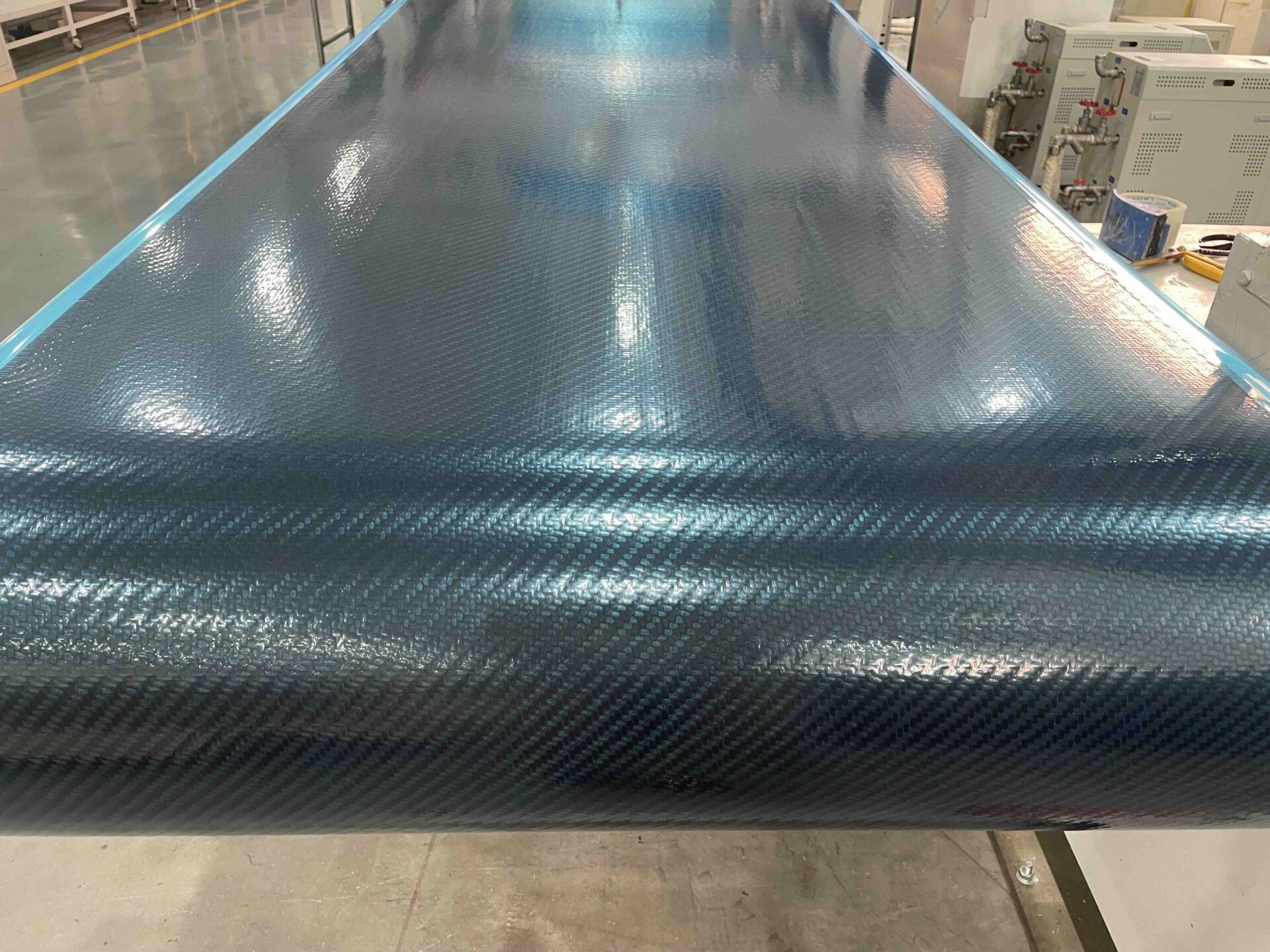

In composite engineering, the fiber-to-resin ratio is critical. Too much resin adds "dead weight" and makes the material brittle, while too little creates dry spots and structural weakness. Prepreg manufacturing machines calibrate this ratio with extreme precision, typically achieving a fiber volume fraction (FVF) of 55–65%. However, experts note that traditional wet layup methods often struggle to exceed a 40–55% FVF and depend heavily on the operator's skill.

Superior Mechanical Performance

The consolidation process for prepreg, often aided by vacuum bagging or autoclaves, significantly reduces defects. Data shows that autoclave-cured prepreg parts can have a void content of less than 1–3%, while wet layup parts often have void contents of 1–5% or higher. This difference translates to higher fatigue resistance and tensile strength.

Cleaner and Safer Processing

Prepreg virtually eliminates the mess associated with mixing liquid resins. It also significantly reduces exposure to volatile organic compounds (VOCs) during the layup phase, creating a safer environment for technicians.

Exploring the Diverse Types of Prepreg Carbon Fiber

Not all prepregs are created equal. Engineers must select the specific type that aligns with their structural goals.

Fiber Architecture

- Unidirectional (UD): In UD prepreg, all carbon fibers run in parallel. This provides maximum strength in a single direction, making it ideal for components like wing spars or bicycle frames where load paths are predictable.

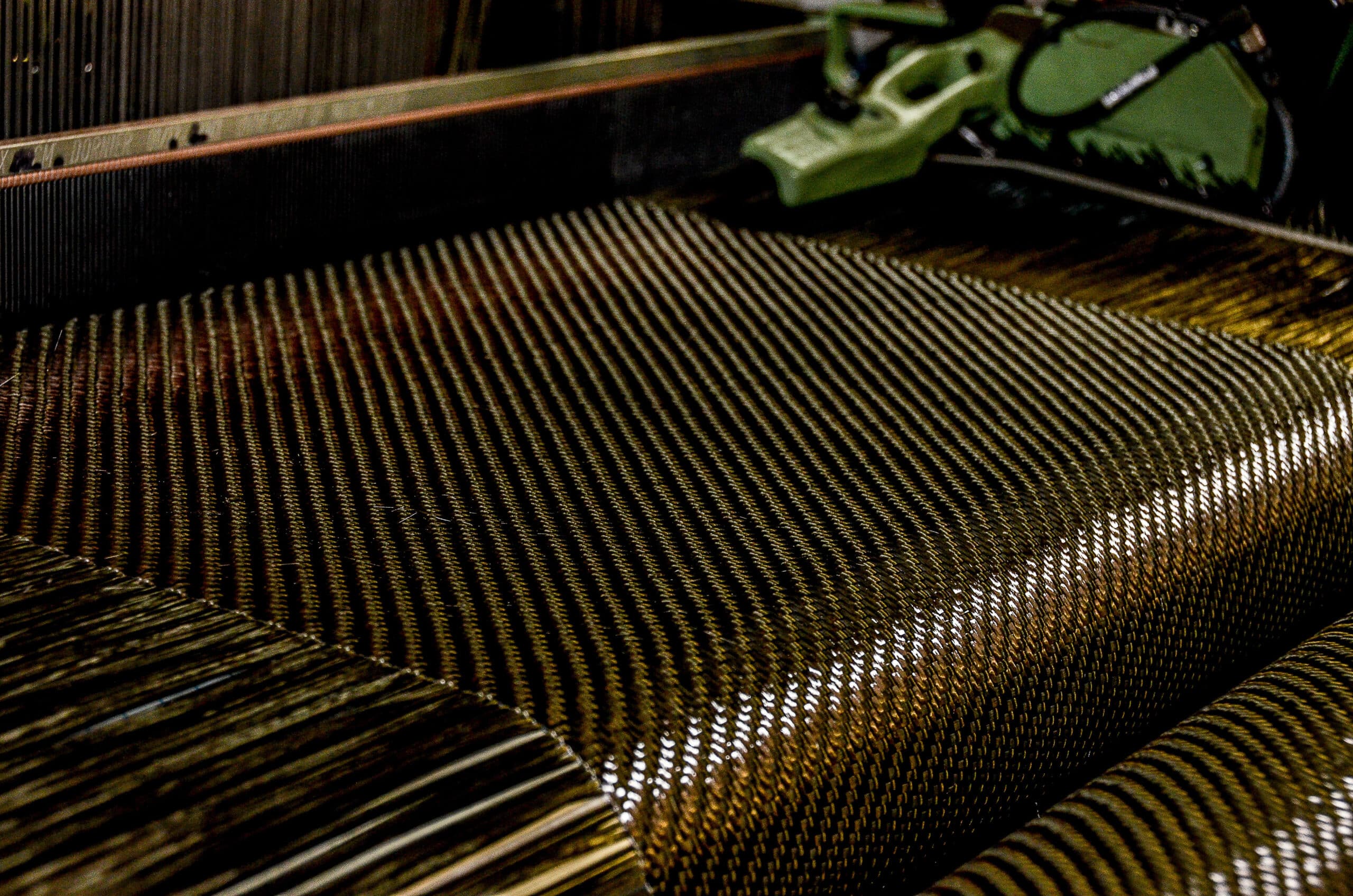

- Woven Fabrics: Common patterns include Plain Weave (checkerboard look) and Twill (diagonal pattern). These offer multi-directional strength and the classic "carbon fiber" aesthetic prized in automotive luxury parts.

Resin Systems: Thermoset vs. Thermoplastic

The vast majority of prepregs use thermoset epoxy resins, which irreversibly cure when heated. However, a new wave of thermoplastic prepregs is emerging. According to Perfelt, these prepregs use resins like PEEK or nylon, which can be melted and reformed. This offers superior impact toughness and the potential for recycling, a major advantage for sustainable manufacturing.

Curing Requirements

- Autoclave Prepregs: These require a pressurized vessel (autoclave) to cure. The pressure (often 80–100 psi) crushes voids, yielding aerospace-grade quality.

- Out-of-Autoclave (OoA): Modern resin chemistries now allow for high-quality curing using only a vacuum bag and an oven, making high-performance composites accessible to smaller workshops.

-

Key Applications: Where Prepreg Carbon Fiber Excels

Aerospace and Defense

The aerospace sector continues to be the primary driver of prepreg innovation. The weight savings provided by carbon fiber directly reduce fuel consumption and increase range. According to Materials International, modern aircraft such as the Airbus A350 XWB and the Boeing 787 Dreamliner are composed of 50–53% composite materials by weight. The shift from aluminum to prepreg carbon fiber has revolutionized airframe design by allowing for more complex aerodynamic shapes and reduced maintenance.

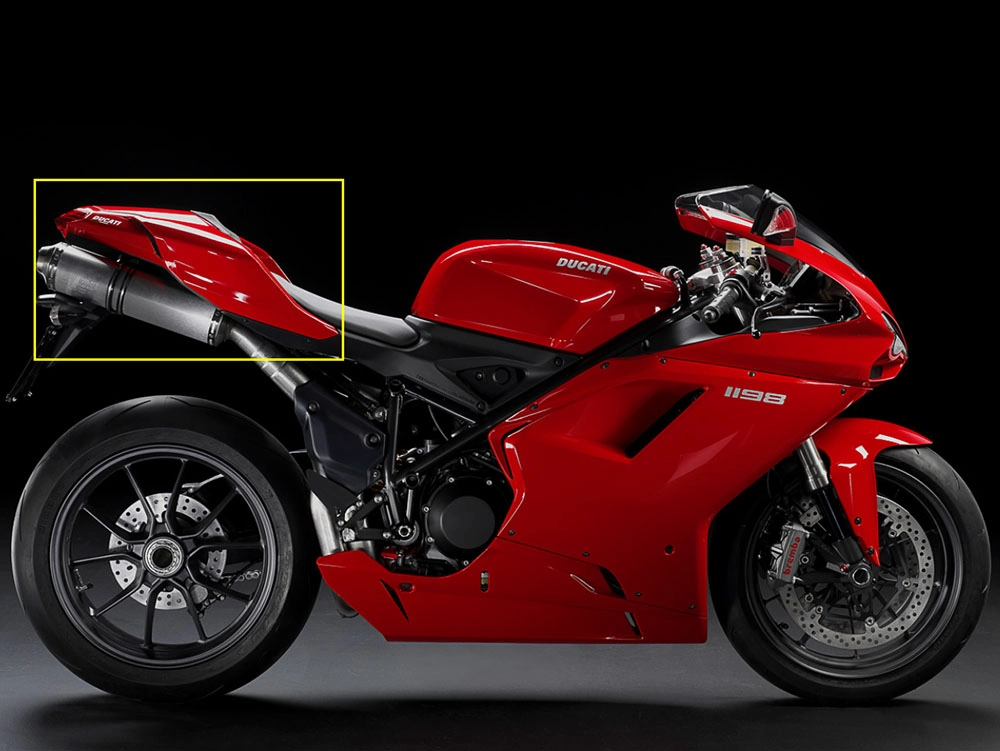

Automotive and Motorsports

While once exclusive to Formula 1, prepreg is filtering down to production vehicles. Future Market Insights indicates that electric vehicle (EV) manufacturers are increasingly adopting prepreg structures to offset the heavy weight of battery packs. In 2023 alone, the adoption of composite structural components in the EV sector saw a significant rise, driven by partnerships between major automakers and composite suppliers.

Sports and Industrial

From the masts of America's Cup yachts to the shafts of professional golf clubs, prepreg delivers the stiffness required for elite sporting equipment. In the industrial sector, it is used to create lightweight robotic arms that can move faster and with greater precision than metal counterparts.

Choosing the Right Prepreg Carbon Fiber for Your Project

Selecting the correct material requires a balance of performance, process, and cost.

- Define Project Requirements: Do you need aesthetic perfection (use a defect-free 2x2 twill) or maximum stiffness (use high-modulus UD tape)?

- Assess Processing Capabilities: Do not buy autoclave-cure prepreg if you only have access to an oven. Ensure your equipment can hit the required ramp-up and soak temperatures (typically 250°F or 350°F).

- Environmental Conditions: Consider the Glass Transition Temperature (Tg). If the part will be near an engine exhaust, you need a high-Tg resin system.

- Supplier Quality: Look for suppliers who provide detailed technical data sheets (TDS) and have a transparent cold-chain history to ensure the material hasn't expired.

-

Future Trends and Innovations in Prepreg Technology

The future of prepreg is bright and green. Conventional autoclave cycles take hours, creating a bottleneck in large-scale production. Current innovations focus on snap-cure resins, which can cure in minutes — similar to the speed of stamping metals.

Moreover, sustainability is one of the key priorities. The sector is working to develop bio-based resins and improve the feasibility of recycled carbon fiber. According to Thomasnet, the trend toward thermoplastic prepregs is gaining momentum because they enable circular manufacturing. Scrap material can be pelletized and recycled, unlike cross-linked thermosets, which end up in landfills.

Conclusion

Prepreg carbon fiber has transformed from a niche aerospace material into the backbone of modern high-performance engineering. By combining the incredible strength of carbon fiber with the precision of factory-impregnated resins, it offers a material solution that is lighter, stronger, and more consistent than any alternative. Whether utilized in the wings of a Dreamliner or the chassis of an electric vehicle, prepreg continues to push the boundaries of what is physically possible. For engineers and innovators, mastering this material is no longer an option—it is a necessity for defining the future of performance.

If you are exploring advanced prepreg solutions or seeking expert guidance, Supreem Carbon is ready to support your next breakthrough.

FAQs

What is the primary difference between prepreg carbon fiber and traditional wet layup?

Prepreg carbon fiber comes pre-impregnated with a precise amount of resin (usually epoxy) from the factory, ensuring an optimal fiber-to-resin ratio and consistent mechanical properties. Wet layup involves manually applying liquid resin to dry fabric, which often results in excess weight, air voids, and variable quality depending on the technician's skill.

Why is prepreg carbon fiber often more expensive than other composite materials?

The higher cost stems from the complex manufacturing process required to impregnate the fiber with exact resin quantities, as well as the need for cold storage (freezing) and refrigerated transport. However, this upfront cost is often offset by reduced labor time, less waste, and the elimination of the need for mixing chemicals, alongside superior final part performance.

How should prepreg carbon fiber be stored?

Standard thermoset prepregs must be stored in a freezer, typically at -18°C (0°F) or colder, to prevent the resin from curing chemically. Under these conditions, they can have a shelf life of 6 to 12 months. If left at room temperature, the resin will begin to cure and the material may become unusable within weeks or even days (its "out-life").

What curing methods are commonly used for prepreg carbon fiber?

Autoclave Curing is the gold standard, using high pressure and heat to maximize consolidation and minimize voids. Out-of-Autoclave (OoA) curing uses vacuum bagging and a standard oven with specialized resin systems designed to remove air without high external pressure.

Can prepreg carbon fiber be used for DIY or hobbyist projects?

Yes, but it requires specific equipment. At a minimum, a DIYer needs a vacuum bagging setup (pump, bag, sealant) and an oven capable of maintaining precise temperatures (usually 250°F to 350°F) for several hours. It is generally not suitable for casual users without temperature-controlled curing means.

What are the main types of weave patterns available for prepreg carbon fiber?

Plain Weave is a stable, simple over-under pattern. Twill Weave (e.g., 2x2) is the most popular for visual parts because it drapes better over curves and has the signature diagonal look. Unidirectional (UD) is not a weave; fibers run in one direction for maximum structural efficiency along load paths.

Is prepreg carbon fiber recyclable?

Traditional thermoset prepregs are difficult to recycle because the resin cannot be melted down once cured. However, the industry is shifting toward thermoplastic prepregs, which can be melted and reshaped, making them much easier to recycle and reuse in new components.

How does resin content affect prepreg performance and processing?

Resin content is measured by weight (e.g., 35-40%). An optimal content ensures the fibers are fully held together without adding unnecessary weight. Too little resin causes "pinholes" and dry spots; too much resin creates a brittle, heavy part with lower specific strength.

Supreem Carbon new bike carbon fiber parts development plan.

What Are the Most Common Uses of Carbon Fiber in 2025?

2025 Ducati Panigale V4/V4S Carbon Fiber Body Kit released by Supreem Carbon.

How Long Does Carbon Fiber Last? Unveiling the Durability of a Tech Marvel

Is carbon fiber good for cars?

Fabricante de fibra de carbono para motocicletas de alta calidad de China

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

For Products

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

BMW S1000RR Carbon Fiber Lower Side Fairings Custom

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover

Kawasaki ZX10R Carbon Fiber Front Fender

Introducing the Supreem carbon fiber front fender, designed specifically for the Kawasaki ZX10R. Crafted with precision and expertise, it is the epitome of quality and performance. Made from high-quality carbon fiber, our front fender is incredibly lightweight yet extremely strong and durable. Our advanced manufacturing process ensures a perfect fit for the Kawasaki ZX10R, seamlessly integrating with the bike's design.

Supreem Carbon Custom Carbon Fiber Airbox Cover for Honda CBR1000RR-R

This carbon fiber tank cover can directly replace the ABS part, giving your CBR1000RR-R a fantastic and unique carbon fiber look.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram