Carbono Supremo

A Suprema Carbon, fundada em 2017, é um fabricante confiável especializado empeças de fibra de carbono personalizadaspara scooters, automóveis e motocicletas elétricos. Combinando pesquisa, design, produção e vendas em um só lugar, oferecemos componentes de fibra de carbono leves, duráveis e de alta qualidade, personalizados para aprimorar o desempenho e o apelo estético do seu veículo.

Nossa expertise está em tecnologias avançadascomposto de fibra de carbonotecnologia, permitindo-nos criar peças inovadoras e de engenharia de precisão, resistentes e leves. Seja para modificações personalizadas ou acessórios de reposição, a Supreem Carbon oferece mais de 1.000 produtos, incluindo mais de 500 soluções personalizadas, projetadas para atender a diversos requisitos.

Nossa fábrica ocupa 4.500 metros quadrados e emprega 45 especialistas qualificados, dedicados a manter um rigoroso controle de qualidade. Com uma produção anual de aproximadamente 4 milhões de dólares, focamos em combinar funcionalidade com estilo. Nossas peças de fibra de carbono para scooters elétricos são ideais para pilotos que buscam maior durabilidade, velocidade e um visual moderno e elegante.

Na Supreem Carbon, a satisfação do cliente é nossa prioridade. Trabalhamos em estreita colaboração com você para garantir que cada produto se encaixe perfeitamente e ofereça o máximo desempenho. Escolha nossafibra de carbono personalizadapeças para atualizar sua scooter elétrica com materiais de última geração que resistem ao teste do tempo, ao mesmo tempo em que reduzem o peso e melhoram o manuseio.

Descubra como a Supreem Carbon pode transformar sua experiência com scooter elétrica com materiais inovadores, leves e elegantes.peças de fibra de carbonofeito especialmente para você. Visite (https://www.supreemcarbon.com/) para explorar nossa linha completa de produtos e opções de personalização.

Exibição detalhada

Nossas vantagens

Sugestões de desenvolvimento profissional

Nossos engenheiros fornecerão aos clientes sugestões de desenvolvimento profissional com base em diferentes produtos e diferentes usos.

Nossos produtos são meticulosamente fabricados com material de fibra de carbono premium, conhecido por suas propriedades leves e duráveis.

Amostras grátis

Para projetos específicos de desenvolvimento de produtos, forneceremos aos clientes um conjunto de amostras grátis.

Consulta de projeto

Nossos designers fornecerão aos clientes análises de viabilidade de projetos e orçamentos com base nas ideias e conceitos de design ou desenhos fornecidos pelos clientes.

Perguntas frequentes

Quais são as vantagens da fibra de carbono?

Alta relação resistência-peso

É mais forte do que muitos materiais tradicionais, como aço e alumínio. Essa alta relação resistência-peso permite a criação de componentes leves que mantêm a integridade estrutural e a durabilidade.

Leve

Uma das vantagens mais significativas da fibra de carbono é sua baixa densidade, contribuindo para estruturas leves. Essa propriedade é particularmente crucial em indústrias onde a redução de peso é uma prioridade, como aeroespacial, automotiva e equipamentos esportivos.

Resistente à corrosão e produtos químicos

A fibra de carbono é inerentemente resistente à corrosão, tornando-a um material ideal para aplicações expostas a ambientes agressivos ou substâncias corrosivas. Essa propriedade contribui para a longevidade dos componentes e reduz os requisitos de manutenção. A fibra de carbono tem boa resistência química, tornando-a adequada para uso em ambientes onde a exposição a produtos químicos ou solventes agressivos é uma preocupação. Essa resistência aumenta a durabilidade do material em vários ambientes industriais.

Tolerante a altas temperaturas

A fibra de carbono exibe excelente estabilidade térmica e resistência a altas temperaturas. Isso a torna adequada para aplicações em que os componentes são expostos a temperaturas elevadas, como nas indústrias aeroespacial e automotiva.

Baixa expansão térmica

A fibra de carbono tem um baixo coeficiente de expansão térmica, o que significa que ela se expande ou contrai minimamente com mudanças de temperatura. Essa propriedade contribui para a estabilidade dimensional, tornando os componentes de fibra de carbono confiáveis em condições de temperatura variáveis.

Apelo estético

A fibra de carbono tem uma aparência moderna e de alta tecnologia, contribuindo para seu apelo estético. Essa propriedade é alavancada em bens de consumo, componentes automotivos e equipamentos esportivos onde o apelo visual é importante.

Quanto tempo demora o pedido de produtos personalizados?

Isso depende da complexidade e do ciclo de produção do molde do produto. A primeira amostra estará pronta em 2-3 semanas após o molde terminar.

Quando a Supreme Carbon foi fundada?

Nossa empresa foi formalmente estabelecida no início de 2017.

O que o cliente precisa preparar?

1. Envie seu design/ideia/desenho 3D.

2. Confirmação de cotação do fornecedor.

3. Primeiro exemplo de feedback.

Caso tenha alguma dúvida sobre nossos produtos ou serviços, sinta-se à vontade para entrar em contato conosco.

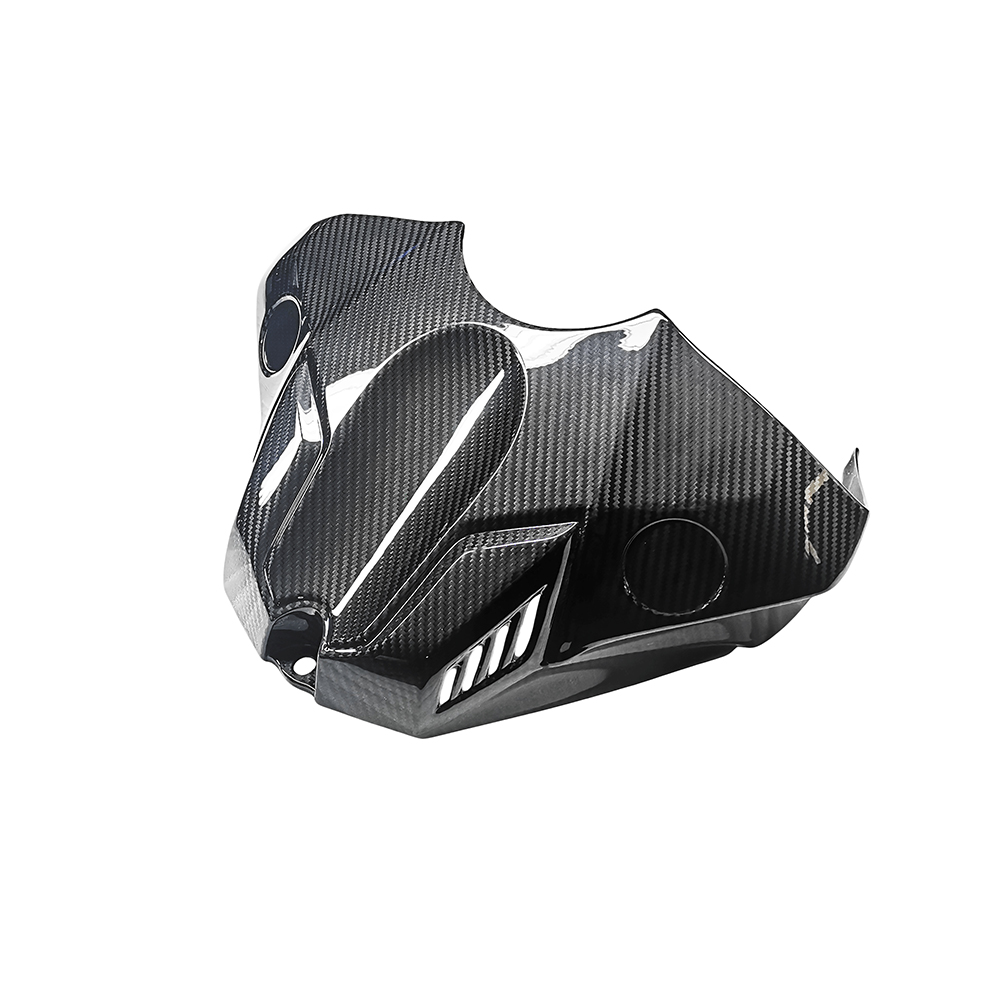

Kawasaki H2 Carenagem frontal de fibra de carbono

Ducati Panigale V4 Carbon Fiber Belly Pan Personalizado

BMW S1000RR Carenagens laterais inferiores de fibra de carbono personalizadas

Protetor de corrente em fibra de carbono Aprilia Tuono V4

© 2024 Suprema Carbon Todos os direitos reservados.

Facebook

Pinterest

LinkedIn

Instagram