How cost-effective are carbon-fiber composites for defense applications? | Insights by Supreem Carbon

Understanding the Cost-Effectiveness of Carbon-Fiber Composites in Defense Applications

Carbon-fiber composites have gained prominence in defense applications due to their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. However, their cost-effectiveness remains a critical consideration for defense procurement. This article delves into the key aspects of carbon-fiber composites, addressing common questions and providing insights for informed decision-making.

1. What Are the Key Advantages of Carbon-Fiber Composites in Defense?

High Strength-to-Weight Ratio: Carbon-fiber composites are significantly lighter than traditional metals like steel and aluminum, enhancing mobility and fuel efficiency in military vehicles and equipment. For instance, the Airbus A350 XWB utilizes carbon-fiber composites for wing spars and fuselage components, contributing to its lightweight design.

Corrosion Resistance: Unlike metals, carbon-fiber composites are highly resistant to corrosion, reducing maintenance costs and extending the lifespan of defense assets operating in harsh environments.

Design Flexibility: The versatility of carbon-fiber composites allows for complex geometries and tailored mechanical properties, enabling the development of specialized defense components.

2. What Are the Challenges and Disadvantages of Using Carbon-Fiber Composites?

High Initial Costs: The production of carbon-fiber composites involves expensive raw materials and complex manufacturing processes, leading to higher upfront costs compared to traditional materials.

Repair and Maintenance: Repairing carbon-fiber components can be more challenging and costly than repairing metal structures. Unlike metals, which can often be welded or patched relatively easily, composite repairs often require careful surface preparation, precise fiber alignment, and controlled curing conditions to restore the original strength of the structure.

Limited Impact Resistance: While carbon-fiber composites are strong, they can be susceptible to damage from sharp, concentrated impacts, leading to delamination or fiber breakage.

3. How Do Carbon-Fiber Composites Compare to Traditional Materials in Terms of Cost?

While carbon-fiber composites offer superior performance, their higher initial costs can be a significant factor. For example, a square meter of carbon pre-preg costs approximately 30-50 EUR, and manufacturing a composite 2mm thick requires 4-5 layers. Additionally, advanced production methods like autoclaving require expensive equipment, such as autoclaves costing around USD 500,000. Consequently, the final product costs several times more than one made from aluminum.

4. What Are the Procurement Considerations for Carbon-Fiber Composites?

Material Selection: Understanding the different types of carbon-fiber composites, such as unidirectional, woven, and chopped fiber composites, is essential for selecting the right material for specific defense applications. ((https://www.supreemcarbon.com/article/carbon-fiber-as-a-composite-industrial-procurement-guide.html?utm_source=openai))

Manufacturing Methods: Familiarity with manufacturing techniques like tailored fiber placement and 3D composites can influence cost and performance outcomes.

Supplier Evaluation: Assessing suppliers' capabilities, quality control measures, and compliance with defense standards is crucial for ensuring reliable procurement.

5. Are There Any Environmental Considerations with Carbon-Fiber Composites?

Recycling Challenges: Carbon-fiber composites are challenging to recycle due to their complex composition, leading to environmental concerns and potential waste accumulation.

Environmental Impact: The production and disposal of carbon-fiber composites can have environmental implications, necessitating sustainable practices in their lifecycle management.

6. How Do Carbon-Fiber Composites Perform in Military Applications?

Military Vehicles: Carbon-fiber composites are used to reinforce existing military vehicles, providing improved protection without adding excessive weight.

Aerospace: The aerospace industry utilizes carbon-fiber composites for components like wing spars and fuselage parts, contributing to lighter and more efficient aircraft designs.

7. What Are the Future Trends in Carbon-Fiber Composites for Defense?

Advancements in manufacturing technologies, such as tailored fiber placement and 3D composites, are expected to reduce costs and enhance the performance of carbon-fiber composites in defense applications. Additionally, ongoing research into recycling methods aims to address environmental concerns associated with these materials.

8. How Does Supreem Carbon Address These Considerations?

Supreem Carbon specializes in providing high-quality carbon-fiber composite solutions tailored for defense applications. With a focus on performance, cost-effectiveness, and sustainability, Supreem Carbon offers:

Customized Solutions: Tailored composite materials designed to meet specific defense requirements.

Advanced Manufacturing: Utilization of cutting-edge technologies to optimize performance and reduce costs.

Sustainability Initiatives: Commitment to environmentally responsible practices, including research into recycling methods.

By partnering with Supreem Carbon, defense organizations can leverage the benefits of carbon-fiber composites while addressing cost and environmental considerations.

Meta Title: Cost-Effectiveness of Carbon-Fiber Composites in Defense

Meta Description: Explore the advantages, challenges, and procurement considerations of carbon-fiber composites in defense applications, including cost implications and performance benefits.

Keywords: carbon-fiber composites, defense applications, cost-effectiveness, procurement considerations, Supreem Carbon

URL Alias: carbon-fiber-composites-defense-cost-effectiveness

New arrivals- BMW CSL style carbon fiber front grille released by Supreem carbon!!

The 5 Questions You've Always Had About Carbon Fiber

Supreem carbon Auto part new arrivals

Ducati DesertX 2022 new arrivals!

Supreem Carbon New Motorcycle Carbon Parts Development Plan.

Carbon Fibers: What Are They and Why Are They Everywhere? (Production, Properties, and Uses Explained)

For Products

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

For Facotry

How many employees of Supreem carbon?

We have over 50 employees, including over 40 skilled workers, 3 R&D designers, and 5 QC professionals and so on.

For Customized Service

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

Honda CBR1000RR-R Carbon Fiber Tank Side Panels

Ducati Monster 937 Carbon Fiber Rear Fender

Porsche GT3RS Carbon Fiber Full Sets Aerodynamics Kits

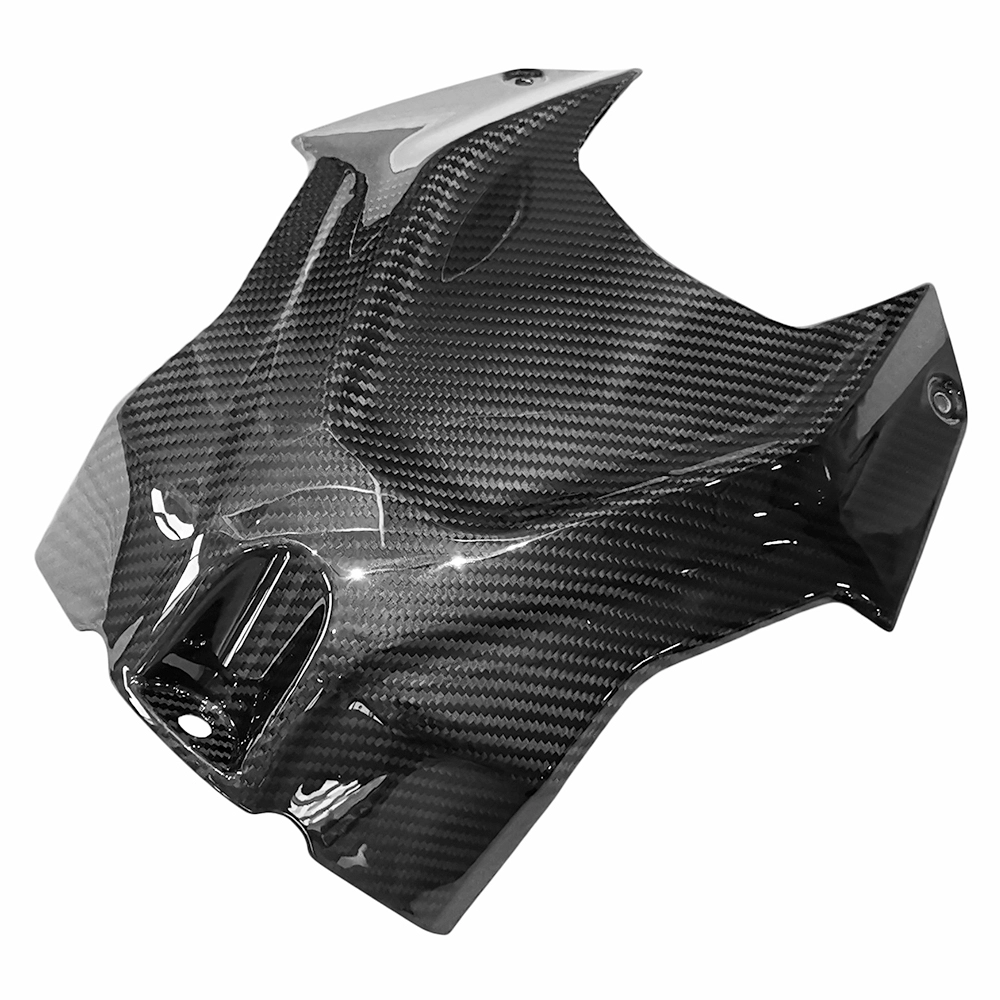

BMW S1000RR S1000R Carbon Fiber Tank Airbox Cover

Leave a message

Have a question or inquiry about our carbon fiber composite products? Leave us a message here and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram