Carbon Fiber Cowling LWR Revolutionizing Aircraft Engine Design

The aerospace industry is constantly striving for improvements in aircraft performance and fuel efficiency. One area of focus is the development of advanced materials for engine components. Carbon fiber composites have emerged as a game-changer, providing lightweight and high-strength properties. In this article, we will explore the concept of Carbon Fiber Cowling LWR and its impact on aircraft design.

What is Carbon Fiber Cowling LWR ?

The Carbon Fiber Cowling LWR (Low Weight Ratio) refers to the use of carbon fiber composites in the construction of the engine cowling—an essential component that encloses the engine and protects it from external elements. Traditionally, cowling materials have included aluminum or fiberglass, but carbon fiber is now being widely adopted due to its superior properties.

Advantages of Carbon Fiber Cow LWR:

Weight: Carbon fiber composites offer a remarkable strength-to-weight ratio By incorporating carbon fiber into the cowling, the overall weight of the aircraft can be significantly reduced, leading to improved fuel efficiency and increased payload capacity.

Enhanced Durability: Carbon fiber composites exhibit excellent resistance to corrosion, fatigue, and impact. This increased durability ensures a longer service life for theling, reducing maintenance and replacement costs.

Noise Reduction: Carbon fiber composites possess inherent vibration-damping characteristics. The use of Carbon Fiber Cowling LWR can help reduce engine noise levels, ultimately improving the passenger experience and complying with stringent noise regulations.

Thermal Insulation: Carbon fiber has outstanding thermal insulation properties. It can effectively limit heat transfer from the engine to the surroundings, enhancing safety and reducing the risk of thermal damage.

Challenges and Future Developments:

Although Carbon Fiber Cowling LWR offers numerous advantages, several challenges need to be addressed. The cost of carbon fiber composites remains relatively high compared to traditional materials. However, ongoing research and advancements in manufacturing processes are gradually reducing the cost barrier. Additionally, further studies are needed to optimize the design and manufacturing techniques of carbon fiber cowling to ensure quality and reliability.

Looking ahead, the aerospace industry is expected to witness continuous progress in the utilization of carbon fiber composites. With advancements in material science and manufacturing technologies, we can anticipate even lighter, stronger, and more efficient Carbon Fiber Cowling LWR in the future.

The incorporation of Carbon Fiber Cowling LWR into aircraft engine design represents a significant leap forward in the aerospace industry Its lightweight properties, durability, and noise reduction capabilities make it a desirable choice for improved aircraft performance and passenger experience. As carbon composite technologies continue to advance, can expect to see wider adoption of this innovation, shaping the future of aircraft engine design and to a more sustainable aviation industry.

Customize Your Ride: Top Makers of Automotive Carbon Fiber Parts

Carbon Fibers: What Are They and Why Are They Everywhere? (Production, Properties, and Uses Explained)

Application Advantages of Carbon Fiber in Automobile Chassis Brackets

Asia's Top Carbon Fiber Motorcycle Accessory Brand

Xiaomi SU7 Aerodynamic Carbon Fiber Body Kits Released by Supreem Carbon.

Is carbon fiber good for cars?

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

For After-sales Service

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

For Facotry

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

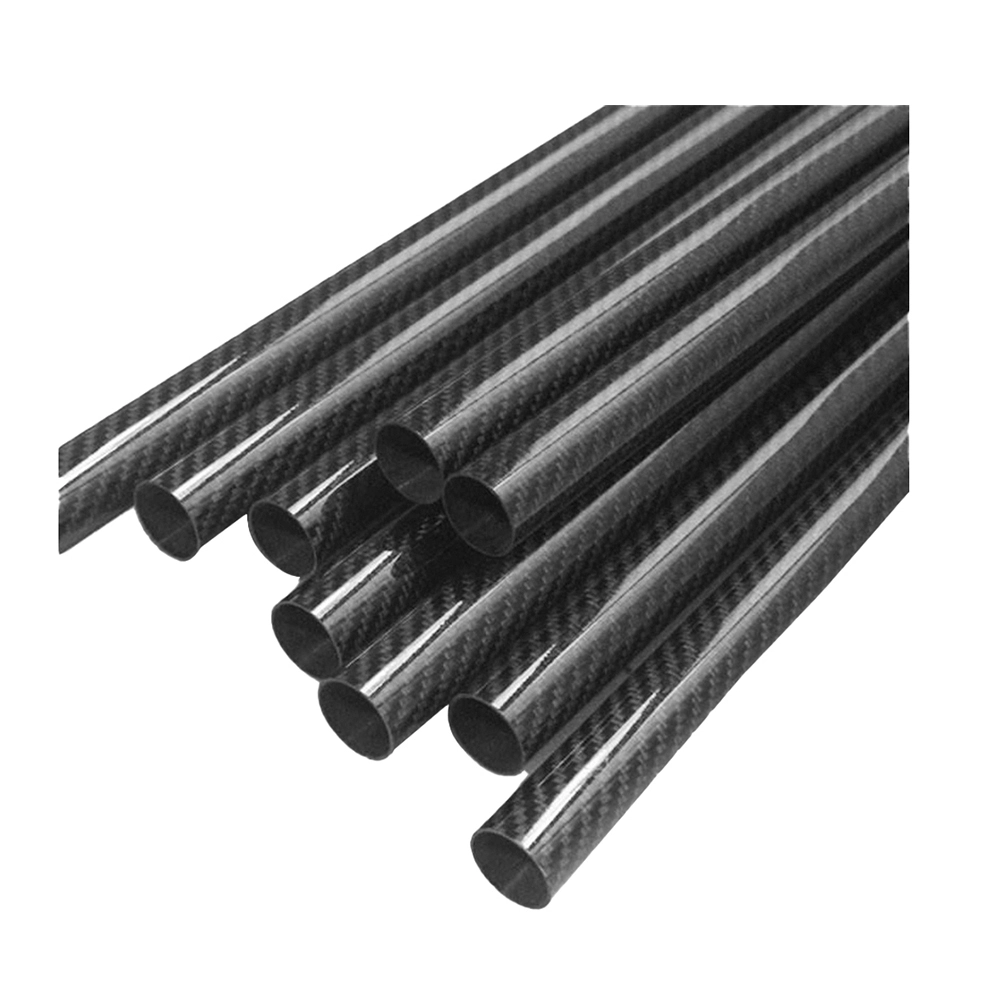

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Carbon Fiber Steering Wheels Wrapping Customization

We can provide customized solutions for different styles of carbon fiber steering wheels according to customer needs. All you need to do is provide us with the original parts. We will provide a variety of material options for you. Upgrade your driving experience!

Kawasaki Z650 Carbon Fiber Tank Side Panels

Porsche GT3RS Carbon Fiber Full Sets Aerodynamics Kits

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram