What can you make out of carbon fiber? | Supreem Carbon Guide

What Can You Make Out of Carbon Fiber?

Choosing the right material for your next project is crucial. This article explores the diverse applications of carbon fiber, addressing common questions and highlighting its unique capabilities for professionals in the carbon fiber parts industry. We'll delve into the possibilities of carbon fiber fabrication, from the intricate to the massive.

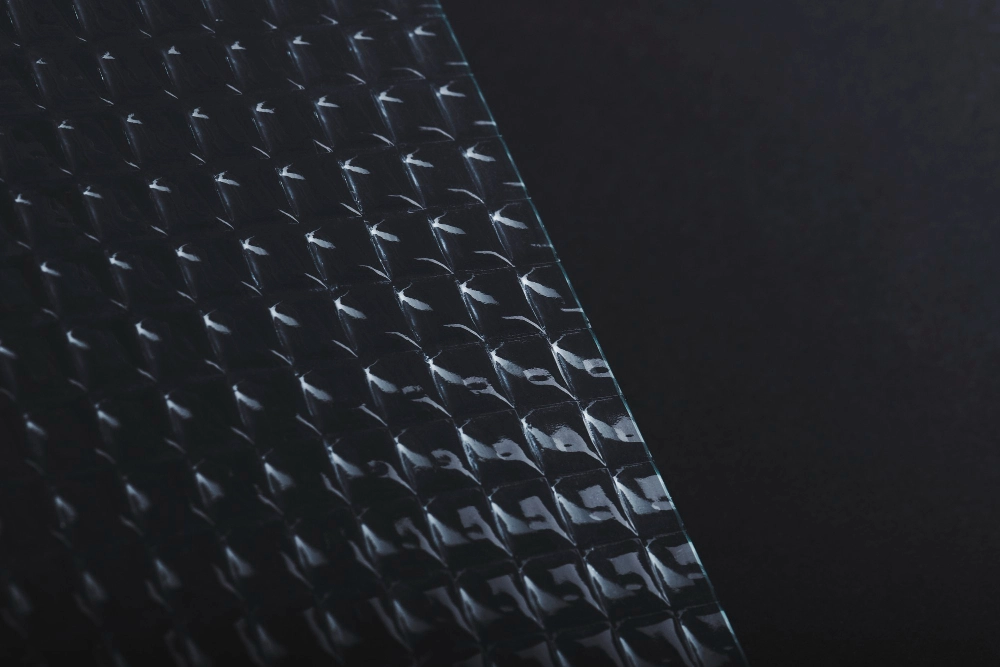

The Versatility of Carbon Fiber Parts

Carbon fiber's exceptional strength-to-weight ratio makes it ideal for a vast array of applications. Its high tensile strength, stiffness, and resistance to fatigue make it a superior material for high-performance components. This leads to its use in various sectors.

Industries Utilizing Carbon Fiber Parts

* Aerospace: Carbon fiber is a cornerstone of modern aircraft and spacecraft construction, used in everything from airframes to internal components. Its lightweight nature significantly improves fuel efficiency.

* Automotive: High-performance vehicles frequently incorporate carbon fiber parts in body panels, chassis components, and internal structures to enhance performance and reduce weight.

* Sporting Goods: From bicycle frames to tennis rackets, the unique properties of carbon fiber improve performance and durability in sporting goods. This makes for lighter, stronger equipment.

* Medical Devices: In the medical field, carbon fiber’s biocompatibility and strength are valuable in the creation of prosthetics and other medical implants.

* Industrial Applications: The strength and durability of carbon fiber make it suitable for industrial applications, including pressure vessels, robotic components, and structural reinforcement.

Designing with Carbon Fiber: Considerations and Techniques

Designing with carbon fiber requires specialized knowledge. The process involves careful consideration of fiber orientation, resin selection, and manufacturing methods. Common methods include:

* Autoclave molding: This method uses high pressure and temperature to cure the carbon fiber composite, resulting in high-quality parts.

* Resin transfer molding (RTM): This process is cost-effective for high-volume production, providing consistent quality.

* Pultrusion: A continuous process ideal for producing long, consistent profiles.

Understanding these techniques and their suitability for different project requirements is essential for success.

Beyond the Basics: Advanced Carbon Fiber Applications

The possibilities extend beyond standard applications. Advanced techniques are unlocking new possibilities, including:

* 3D-printed carbon fiber parts: Additive manufacturing is revolutionizing the creation of complex carbon fiber components with intricate designs.

* Carbon fiber nanotubes: These extremely small structures offer even greater strength and potential for specialized applications.

Choosing the right carbon fiber material and manufacturing process requires expertise. Supreem Carbon offers solutions for your specific needs. Contact us today.

Die einflussreichste Marke eines Kohlefaserherstellers in Asien

Supreem Carbon Auto parts new arrivals!

The Ultimate Guide to Carbon Fiber in Aerospace Applications

Research on the Causes of Yellowing of Carbon Fiber Products.

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

The 5 Questions You've Always Had About Carbon Fiber

For Facotry

When is Supreem carbon founded?

Our company formally established in early 2017.

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What custom customer need to prepare?

1. Send Your Design/Idea/3D drawing.

2. Supplier Quotation Confirmation.

3. Firts Sample Feedback.

For After-sales Service

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

For Products

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

Yamaha R1 R1M Carbon Fiber Undertail

Ducati Panigale 1199 1299 899 959 V2 Carbon Fiber Suspension Cover

Ducati Monster 937 Carbon Fiber Rear Fender

Ducati Panigale V4 Carbon Fiber Side Fairings

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram