CFRP vs Pre-Preg Carbon Fiber: What’s the Difference and Which Is Better for Your Project?

Carbon fiber is a highly sought-after material in industries ranging from automotive to aerospace due to its exceptional strength-to-weight ratio. Within the realm of carbon fiber materials, two terms often arise: CFRP (Carbon Fiber Reinforced Polymer) and pre-preg carbon fiber. While they are related, they refer to different stages and types of carbon fiber products, each with unique characteristics and applications.

Carbon fiber is a highly sought-after material in industries ranging from automotive to aerospace due to its exceptional strength-to-weight ratio. Within the realm of carbon fiber materials, two terms often arise: CFRP (Carbon Fiber Reinforced Polymer) and Pre-Preg Carbon Fiber. While they are related, they refer to different stages and types of carbon fiber products, each with unique characteristics and applications.

What Is CFRP (Carbon Fiber Reinforced Polymer)?

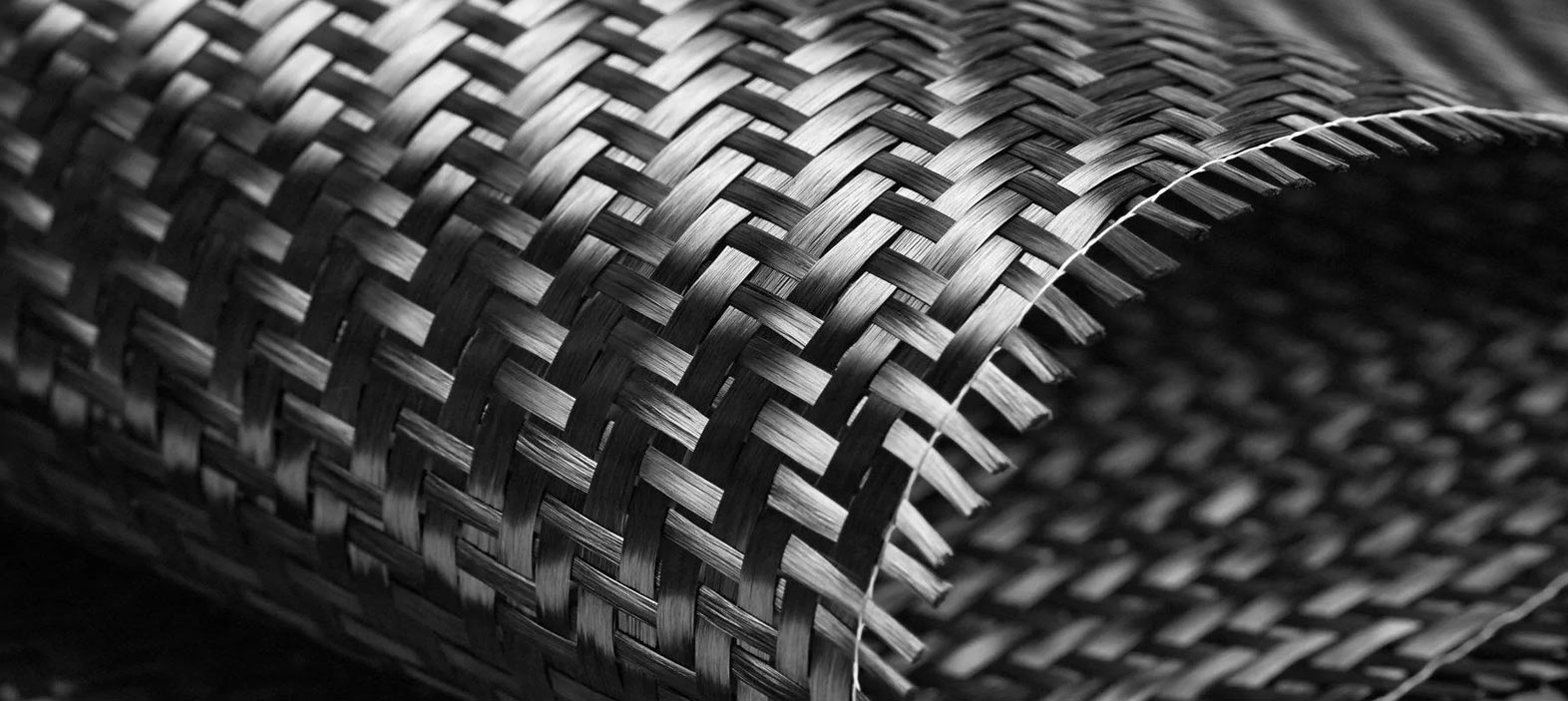

CFRP, or Carbon Fiber Reinforced Polymer, is a composite material composed of carbon fiber reinforcements embedded in a polymer matrix. This combination creates a material that is both incredibly strong and lightweight, making it ideal for high-performance applications. CFRP is commonly used in the production of structural components for cars, aircraft, and sporting equipment, where strength and weight are critical factors.

The manufacturing process of CFRP typically involves layering sheets of carbon fiber fabric, which are then impregnated with a resin (usually epoxy) and cured to form a rigid structure. This process allows for the creation of complex shapes and structures that maintain high tensile strength and stiffness. Once cured, the CFRP component is ready for use and exhibits the durability and performance characteristics that make it so valuable in demanding applications.

What Is Pre-Preg Carbon Fiber?

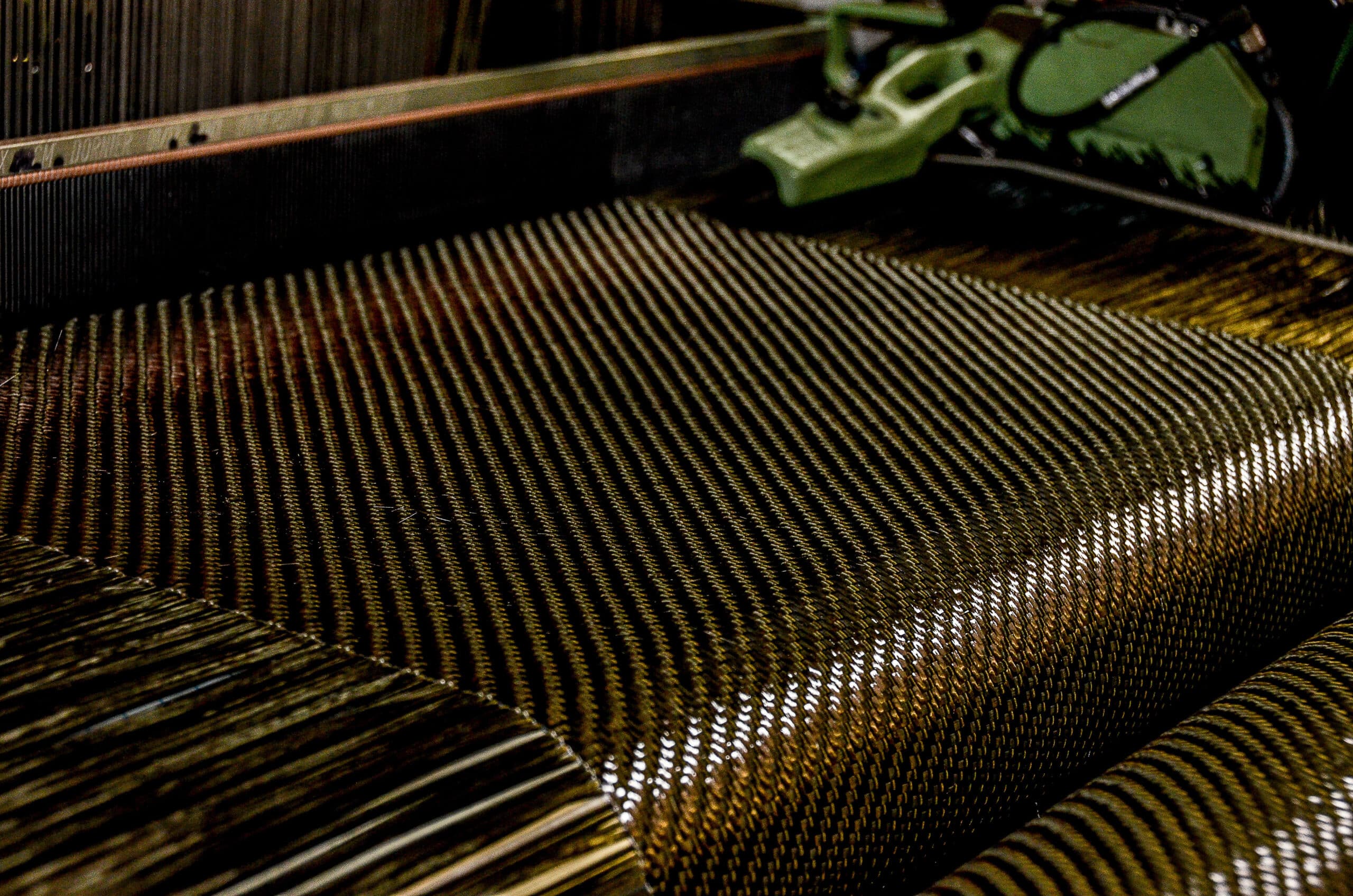

Pre-Preg Carbon Fiber, on the other hand, refers to carbon fiber fabric that has already been impregnated with a specific amount of resin, typically in a controlled factory environment. The term "pre-preg" stands for pre-impregnated, meaning the fabric comes pre-coated with resin, ready to be laid into molds and cured. Pre-preg carbon fiber offers precise resin content, which leads to consistent quality and performance in the final product.

The advantage of pre-preg materials is the level of control they offer over the manufacturing process. Since the resin content and fiber alignment are pre-determined, pre-preg carbon fiber allows for uniform production with minimal waste. This results in higher-quality components with predictable mechanical properties, making it a preferred choice for applications requiring exacting standards, such as aerospace, motorsports, and high-end consumer goods.

CFRP vs Pre-Preg Carbon Fiber: Key Differences

The primary difference between CFRP and pre-preg carbon fiber lies in the manufacturing process and the stage at which the resin is introduced. CFRP involves the manual impregnation of dry carbon fiber fabric with resin during the manufacturing process, while pre-preg carbon fiber comes with the resin already infused.

In summary, both CFRP and pre-preg carbon fiber offer significant advantages, but the choice between them depends on the specific requirements of the application. CFRP offers versatility and can be tailored during production, while pre-preg carbon fiber provides consistency and precision, making it ideal for high-performance and high-precision applications.

Choosing the Right Carbon Fiber Material for Your Application

The choice between CFRP and pre-preg carbon fiber depends on your project's specific requirements, including strength, precision, cost, and production volume.

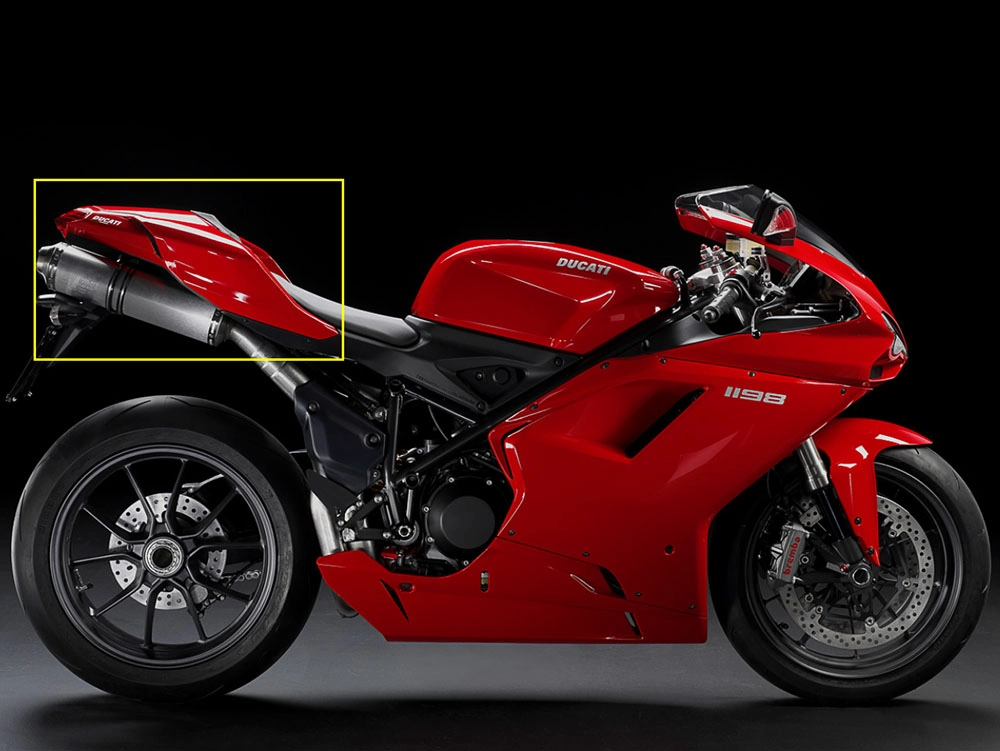

If your design involves complex shapes or custom configurations, traditional CFRP may be the better option. CFRP allows for greater flexibility during the resin impregnation process and is ideal for medium-scale production involving manual craftsmanship. CFRP is widely used for automotive body kits, sports equipment, drones, and structural reinforcements because it offers a great balance between performance and affordability.

On the other hand, pre-preg carbon fiber is ideal for projects that demand high precision, minimal weight variation, and consistent mechanical performance. Because pre-preg materials have controlled resin content, they ensure uniformity and a superior surface finish, making them the preferred choice for aerospace components, racing vehicles, and premium sports gear. Although pre-preg fabrication requires special curing equipment, the results justify the investment with exceptional durability and visual appeal.

Understanding the strengths of each type helps you make the most effective material decision for your project, whether you need flexibility for creative design or unmatched precision for engineering performance.

Why Choose Supreem Carbon as Your Carbon Fiber Partner?

At Supreem Carbon, we combine advanced technology, expert craftsmanship, and premium materials to deliver high-performance carbon fiber solutions. We provide custom CFRP and pre-preg parts with exceptional precision, durability, and finish for applications ranging from automotive to aerospace. Our strong R&D capabilities, strict quality control, and full OEM/ODM support ensure that every product meets international standards.

Whether you need lightweight automotive parts or aerospace-grade composites, contact Supreem Carbon today to discover tailored carbon fiber solutions.

Is carbon fiber good for cars?

Ducati monster 937 and BM S1000RR 2016+ new arrivals released!

Custom Xiaomi SU7 Carbon Fiber Parts – Supreem Carbon

Fabricante de fibra de carbono para motocicletas de alta calidad de China

Supreem Carbon Cross-Country Mountain Bike Seat: The Ultimate Lightweight Carbon Fiber Upgrade

Aprilia Tuono V4 2021 new arrivals.

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

For Products

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

Ducati Monster 937 Carbon Fiber Engine Protect Cover

Ducati Monster 821 797 1200 937 Carbon Fiber Front Fender

Chevrolet Corvette C8 Carbon Fiber Paddle Shifters

BMW S1000RR Carbon Fiber Lower Side Fairings Custom

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram