What Are the Most Common Uses of Carbon Fiber in 2025?

In 2025, carbon fiber continues to redefine industries from aerospace to automotive manufacturing. This guide explores its most common applications, from lightweight aircraft structures to advanced EV components, and explains why custom carbon fiber solutions are driving global innovation.

- Introduction

- 1. Aerospace and Aviation

- The Role of Carbon Fiber in Aerospace Innovation

- 2. Automotive Industry

- Lightweight, Strength, and Speed

- The Rise of Custom Carbon Fiber Modifications

- 3. Sports Equipment and Performance Gear

- Performance Beyond Limits

- Customization and Ergonomics

- 4. Construction and Architecture

- Redefining Structural Engineering

- Sustainability and Longevity

- 5. Marine and Wind Energy

- Lighter, Stronger, and More Efficient

- 6. Consumer Electronics

- Modern Design Meets Functionality

- 7. Medical Devices and Robotics

- Revolutionizing Healthcare Equipment

- Precision in robotic

- 8. Future Trends: What's Next for Carbon Fiber in 2025 and Beyond

- Smart integration and mass customization

- Conclusion

Introduction

In the rapidly evolving world of modern materials, carbon fiber is a symbol of strength, precision and innovation. From lightweight aircraft components to durable consumer electronics, this advanced composite material continues to transform industries around the globe.

However, before we explore its modern applications, it is important to understand what carbon fiber is and why it has become such a crucial material in various sectors. Carbon fiber is made from thin strands of carbon atoms tightly woven together and bound with a resin matrix. This combination gives carbon fiber an exceptional strength-to-weight ratio, corrosion resistance and flexibility, making it ideal for industries that require durability and performance.

By 2025, carbon fiber parts will be used in many more sectors than just aerospace and automotive. They have also found their way into sports equipment, construction materials, electronic devices, and even medical technologies. Let's explore the most common applications of carbon fiber this year and why it continues to be the go-to material for engineers and designers worldwide.

1. Aerospace and Aviation

Few industries have embraced carbon fiber parts as much as the aerospace and aviation sectors. The demand for materials that are both light and strong has prompted engineers to incorporate carbon fiber composites into the frames, wings and interior structures of aircraft.

The Role of Carbon Fiber in Aerospace Innovation

In the aerospace industry, every kilogram of carbon fiber used translates into significant fuel efficiency and performance gains. The strength of carbon fiber enables aircraft to withstand extreme flight conditions while maintaining aerodynamic precision. Modern jets, such as Boeing’s Dreamliner and Airbus models, rely heavily on carbon fiber for up to 50% of their structures.

Helicopters, drones and space vehicles also benefit from the resilience of carbon fiber against high stress and temperature variations. Additionally, its corrosion resistance extends the lifespan of aircraft parts, dramatically reducing maintenance costs.

By 2025, custom carbon fiber manufacturing will have become commonplace in aviation, enabling engineers to design specialized parts optimized for aerodynamics, efficiency and reduced noise emissions. This flexibility enables aerospace companies to innovate more quickly while maintaining safety and sustainability standards.

To explore how carbon fiber is revolutionizing every corner of the aerospace field, read The Ultimate Guide to Carbon Fiber in Aerospace Applications.

2. Automotive Industry

The automotive industry is one of the largest consumers of carbon fiber parts, and its influence is growing as the demand for sustainable and high-performance products increases.

Lightweight, Strength, and Speed

The lightweight nature of carbon fiber helps to improve fuel efficiency and vehicle performance. Supercar brands such as Ferrari, Lamborghini and McLaren use custom carbon fiber panels, chassis and interior trims to optimize aerodynamics and handling. However, thanks to advancements in production efficiency, carbon fiber is now also being integrated into the structural components of mid-range electric vehicles (EVs) to extend their driving range.

Beyond aesthetics and speed, carbon fiber parts also contribute to safety. The material absorbs impact energy effectively, providing enhanced crash protection compared to steel or aluminum. As automotive designers move towards electric and autonomous vehicles, demand for adaptable, lightweight materials like carbon fiber will only increase.

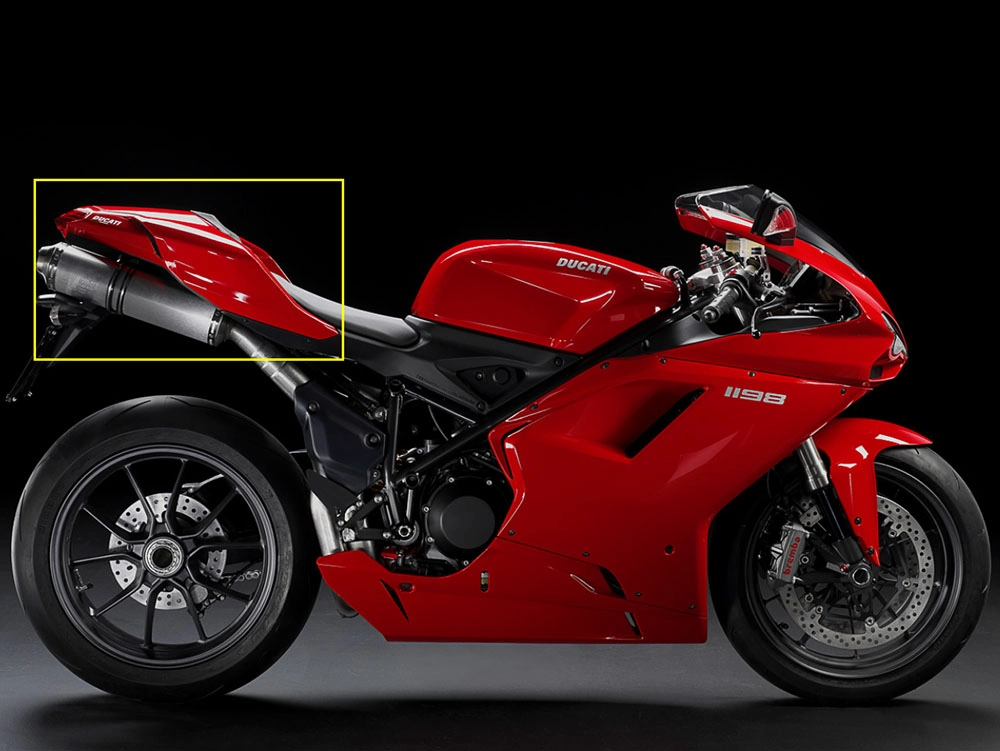

The Rise of Custom Carbon Fiber Modifications

An increasing number of automotive enthusiasts are turning to custom carbon fiber modifications to personalize their vehicles. These modifications range from mirrors and spoilers to entire body kits, reflecting both functionality and style. The combination of performance and luxury has established carbon fiber as a defining feature of modern car design.

3. Sports Equipment and Performance Gear

Carbon fiber has transformed how athletes perform and how sporting goods are made. Its strength and flexibility give sports equipment the edge in performance, precision, and comfort.

Performance Beyond Limits

By 2025, carbon fiber parts will be found in bicycles, tennis rackets, golf clubs, hockey sticks and surfboards. For cyclists, carbon fiber frames offer unbeatable speed for minimal weight, improving acceleration and stability. Similarly, in tennis and golf, the material improves swing control and reduces vibration, helping athletes to perform at their best.

Customization and Ergonomics

Manufacturers now use custom carbon fiber designs to create equipment tailored to an athlete’s unique biomechanics. Whether it's a cyclist's aerodynamic posture or a golfer's preferred swing speed, the adaptability of carbon fiber ensures maximum efficiency.

The continued integration of smart sensors in carbon fiber sports equipment further highlights its importance in modern sports, as it enables motion and performance to be tracked without adding unnecessary weight.

4. Construction and Architecture

Carbon fiber isn’t just for high-speed or high-tech industries—it’s also revolutionizing how we build and reinforce structures.

Redefining Structural Engineering

Carbon fiber parts are increasingly being used by architects and civil engineers in bridges, buildings and restoration projects. The high tensile strength of carbon fiber means it can reinforce concrete, steel or wood without adding bulk. In regions prone to seismic activity, carbon fiber-reinforced polymers (CFRP) are used to reinforce columns and beams, thereby improving the overall resilience of the structure.

Sustainability and Longevity

Carbon fiber is not only strong but also resistant to corrosion, temperature and environmental wear, making it ideal for long-term infrastructure projects. Its low maintenance requirements and long lifespan align with modern green building principles and contribute to sustainability goals in urban development.

5. Marine and Wind Energy

Beyond construction and architecture, carbon fiber is also playing a crucial role in industries that rely on strength, efficiency, and resistance to extreme environments. Two of the most notable examples are marine engineering and wind energy.

Lighter, Stronger, and More Efficient

In marine engineering, carbon fiber composites are essential for constructing lightweight yet durable vessels. From luxury yachts to racing boats, custom carbon fiber hulls reduce drag, enhance speed and resist corrosion caused by exposure to saltwater.

In the field of wind energy, the high stiffness and fatigue resistance of carbon fiber make it indispensable for turbine blades. Lighter blades rotate more efficiently, generating more energy with less mechanical stress. This makes carbon fiber parts vital for the growth of the renewable energy sector, helping to reduce the global carbon footprint.

6. Consumer Electronics

Carbon fiber has also made its way into the devices we use every day, combining style with structural integrity.

Modern Design Meets Functionality

Manufacturers are adopting carbon fiber for phone cases and laptop shells, both for their aesthetic appeal and for the protection they provide. These sleek, lightweight cases are highly resistant to impact, making them popular among tech enthusiasts.

Carbon fiber’s conductive properties also aid thermal management, keeping high-performance electronics cool and efficient. Additionally, custom carbon fiber accessories, such as headphone frames, drone bodies and gaming devices, add a premium touch while ensuring durability.

7. Medical Devices and Robotics

The precision, biocompatibility and lightness of carbon fiber parts make them invaluable in healthcare and robotics.

Revolutionizing Healthcare Equipment

By 2025, carbon fiber will be widely used in prosthetics, wheelchairs, surgical instruments and imaging tables. In prosthetics, for example, the combination of strength and low weight offered by carbon fiber improves patient mobility and comfort.

Precision in robotic

In robotics, custom carbon fiber frames enable robots to move faster and more efficiently without compromising strength. Medical robots in particular benefit from the material's stiffness, which ensures precise movements during surgeries and delicate operations. The material's non-magnetic and radiolucent properties also make it suitable for MRI and X-ray environments.

8. Future Trends: What's Next for Carbon Fiber in 2025 and Beyond

As industries continue to innovate, the potential applications of carbon fiber are expanding all the time. The future lies in sustainable production of carbon fiber through recycled composites and bio-based resins. These innovations will increase the accessibility of carbon fiber parts while reducing environmental impact.

Smart integration and mass customization

Integrating nanotechnology, AI-based manufacturing and 3D printing will further enhance the flexibility of custom carbon fiber designs. From adaptive car panels that respond to environmental changes to aerospace parts that self-monitor for stress, the possibilities are endless.

By 2030, we can expect carbon fiber to become a mainstream material in everything from wearable technology to space infrastructure, continuing its role as one of the most versatile materials of the 21st century.

Conclusion

The journey of carbon fiber from its origins in aerospace innovation to its use in everyday consumer products highlights its incredible adaptability and value. Whether it is used in automotive engineering, sports equipment, architecture or medical technology, the versatility of carbon fiber continues to transform industries and push the boundaries of what is possible.

For those looking to explore the benefits of custom-made carbon fiber solutions, Supreem Carbon is a trusted partner. Founded in 2017, Supreem Carbon specializes in bespoke carbon fiber manufacturing for automobiles, motorcycles, luggage and sports equipment. With a portfolio of over 1,000 product types and 500 customizable parts, Supreem Carbon is committed to innovation, quality and precision, striving to become the world’s leading manufacturer of carbon fiber products.

Carbon Fibers: What Are They and Why Are They Everywhere? (Production, Properties, and Uses Explained)

Custom Xiaomi SU7 Carbon Fiber Parts – Supreem Carbon

Fabricante de fibra de carbono para motocicletas de alta calidad de China

Supreem Carbon New Motorcycle Carbon Parts Development Plan.

Lamborghini Urus engine compartment carbon fiber kit released by Supreem Carbon.

Chinese Carbon Fiber Manufacturer Brands: Supreem Carbon in the Spotlight

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

When is Supreem carbon founded?

Our company formally established in early 2017.

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

Kawasaki ZX10R Carbon Fiber Belly Pan

The carbon fiber belly pan reduces the weight of the car body and provides a unique visual effect. It improves motorcycle performance and provides an excellent driving experience. It is handmade with 100% dry carbon technology and perfectly matches the original car accessories. You can replace the ABS directly.

Kawasaki H2/H2R Carbon Fiber Side Fairing

BMW S1000RR Carbon Fiber Front Fairing Cowls Custom

Chevrolet Corvette C8 Carbon Fiber Bumper Trim Customization

This carbon fiber front grill trim fits C8 OEM parts. Our products are not only lighter than ABS, but they are also corrosion-resistant and have a UV-protective coating. 100% handmade, dry-carbon autoclave process. It can directly replace original vehicle parts.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram