how to get cuustomize carbon fiber on porsche gt3 | Supreem Carbon Expert Guide

- How to Get Customized Carbon Fiber on Porsche GT3

- What Are the Benefits of Custom Carbon Fiber Parts for Porsche GT3?

- How Do Manufacturers Ensure Quality and Fit for Customized Carbon Fiber Parts?

- What is the Typical Price Range for Customized Carbon Fiber Parts for a Porsche GT3?

- How to Install Customized Carbon Fiber Parts on a Porsche GT3?

- Where to Find Reliable Suppliers for Customized Carbon Fiber Parts for Porsche GT3?

How to Get Customized Carbon Fiber on Porsche GT3

Carbon fiber customization for the Porsche GT3 involves selecting high-quality materials, trusted manufacturers, and understanding your vehicle’s specifications to ensure a perfect fit. Start by researching specialized companies that offer tailor-made carbon fiber components such as aerodynamic kits, interior trims, and exterior panels. Websites like Vorsteiner, 3D Carbon, and Anderson Composites are known for their expertise in producing precise carbon fiber parts specifically for Porsche models.

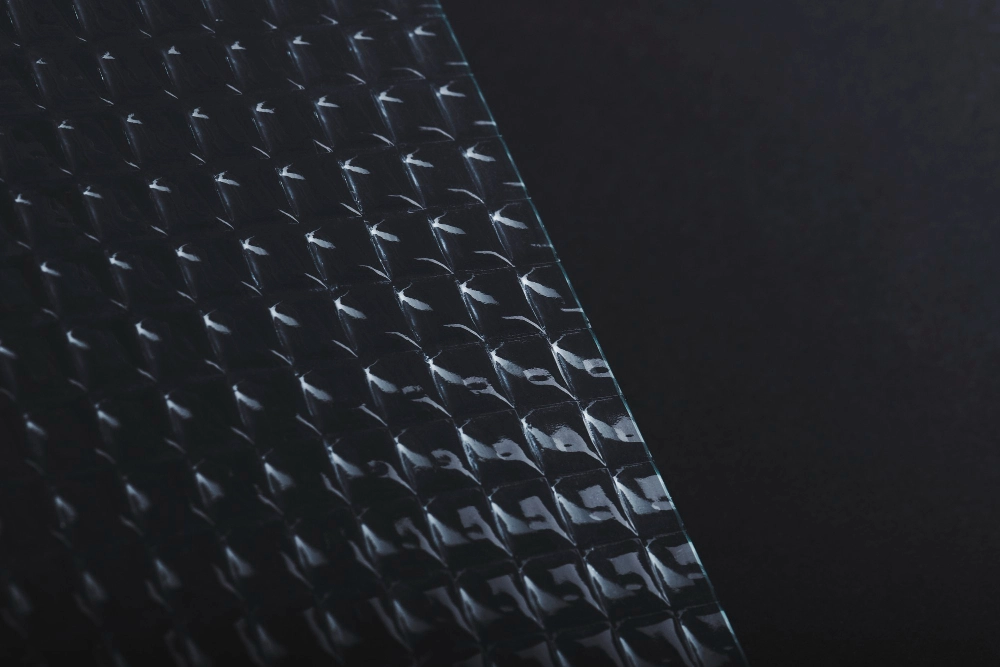

Customization begins with understanding the type of carbon fiber fabric used: typically, 3K or 12K weave patterns are preferred for a balance of aesthetics and strength. You can request specific weave styles, finishes (glossy or matte), and even incorporate brand logos or personalized design elements. Ensure the manufacturer uses high-quality pre-preg carbon fiber with an autoclave curing process to guarantee durability and strength.

What Are the Benefits of Custom Carbon Fiber Parts for Porsche GT3?

Custom carbon fiber parts significantly reduce vehicle weight—up to 50% lighter than traditional materials like steel and aluminum—leading to improved handling, acceleration, and braking performance. Additionally, carbon fiber parts enhance the aesthetic appeal with their High Quality look and can increase the vehicle's resale value. For the Porsche GT3, weight savings contribute to better track and street performance, aligning with the car’s high-performance engineering.

How Do Manufacturers Ensure Quality and Fit for Customized Carbon Fiber Parts?

Top manufacturers utilize 3D scanning and CAD modeling tailored to the Porsche GT3’s specifications to ensure perfect fitment. They opt for aerospace-grade pre-preg carbon fibers and cure parts in autoclaves at upwards of 120°C (248°F) under high pressure to eliminate resin voids and ensure structural integrity. Quality checks include dimensional verification and finish inspections to meet OEM standards. Harmonization with existing GT3 components like mounting points and aerodynamic functionality is also tested in wind tunnels when applicable.

What is the Typical Price Range for Customized Carbon Fiber Parts for a Porsche GT3?

Pricing depends on the complexity of parts and customization level. Basic trim pieces can range from $500 to $1500, while full aerodynamic kits (bumpers, spoilers, side skirts) may range from $5000 to over $15,000. High-end bespoke projects incorporating unique design features or functional enhancements often command High Quality pricing. Consider the cost-benefit ratio: durability, weight savings, and performance gains may justify the investment.

How to Install Customized Carbon Fiber Parts on a Porsche GT3?

Professional installation is recommended to avoid damage to expensive carbon fiber components and ensure safety. Certified shops familiar with Porsche assembly protocols provide service including removal of original parts, precise installation using reinforced fasteners and adhesives, and post-installation inspections. Some lighter components, like interior trims, can be installed by experienced enthusiasts with the right tools and manuals. Proper installation ensures long-lasting performance and maintains warranty conditions.

Where to Find Reliable Suppliers for Customized Carbon Fiber Parts for Porsche GT3?

Reputable suppliers often have strong track records in motorsports and luxury car aftermarket parts. Companies like Vorsteiner, 3D Carbon, Anderson Composites, and Klairs Performance specialize in Porsche carbon fiber products. Verify supplier credentials by checking customer reviews, warranty offers, and certifications such as ISO 9001. Direct communication and consultation help clarify customization options and lead times, typically ranging from 4 to 12 weeks depending on part complexity.

Kawasaki ZX10R 2020+ Full sets carbon fiber products finished testing!

Best 10 car carbon fiber customization suppliers brands in Asia

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

Carbon Fiber Helmet produced by Supreem Carbon.

Supreem Carbon New arrivals alert!

Fabricante de fibra de carbono para motocicletas de alta calidad de China

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

For Order Delivery

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

For Facotry

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

Honda NSX Carbon Fiber Interior Door Handles Replacement

Aprilia Tuono V4 Carbon Fiber Exhaust Cover

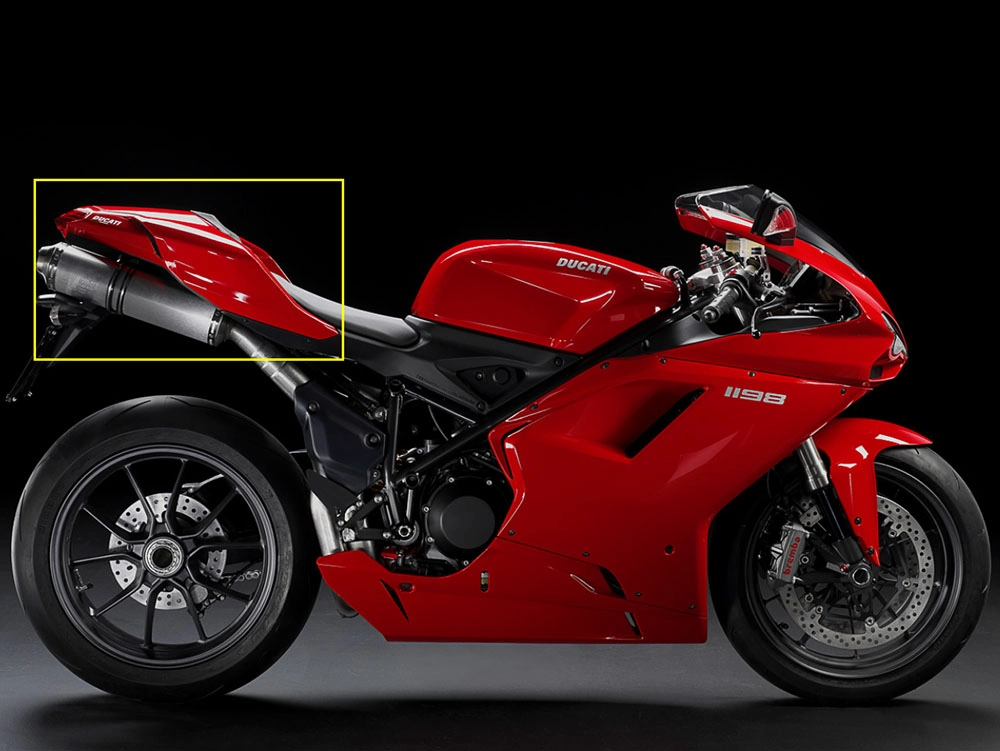

Ducati Panigale 1199 1299 899 959 V2 Carbon Fiber Suspension Cover

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram