How to Manufacture Carbon Fiber Parts | Supreem Carbon Guide

How to Manufacture Carbon Fiber Parts

In the highly specialized field of carbon fiber parts manufacturing, mastering the intricacies is crucial for producing durable, lightweight components. This article delves into the step-by-step process of manufacturing carbon fiber parts, addressing key industry pain points such as cost-efficiency, material handling, and achieving superior performance.

Understanding Carbon Fiber

Carbon fiber is a composite material known for its high strength-to-weight ratio. Essential for aerospace, automotive, and sports industries, understanding its nature is pivotal.

Key Materials and Tools

Materials

Carbon fiber manufacturing starts with selecting the right materials: carbon fiber fabric, resin matrices, and additional reinforcements as needed for the specific application.

Tools

The precision of tools, from cutting files to autoclaves, directly impacts the final carbon fiber part's quality.

Step-by-Step Manufacturing Process

Cutting and Laying

1. Cutting the Preforms: Utilizing templates and precision tools, cut carbon fiber sheets to the desired shape.

2. Lay-Up Process: Layer the sheets according to design specifications to create desired thickness and strength.

Resin Impregnation

The resin plays a crucial role in binding the carbon fibers. Ensure an even distribution for optimal strength.

Molding Techniques

Multiple methods such as vacuum bagging, compression molding, and filament winding help achieve the required form and finishes for different applications.

Curing Process

Autoclaving

An essential step, autoclaving ensures that the part attains its full mechanical properties through high pressure and temperature.

Alternative Curing

Cost-effective alternatives like oven curing may be employed, depending on part requirements.

Quality Control

Rigorous inspection protocols must be followed to certify that the carbon fiber parts meet industry standards, including nondestructive testing and visual inspections.

Conclusion: Ensuring Excellence in Manufacturing

Every step in manufacturing carbon fiber parts must be executed with precision and care. Understanding the process is key to producing high-quality, cost-effective components that meet industry demands.

How Long Do Carbon Fiber Parts Last? | Supreem Carbon

Research on the Causes of Yellowing of Carbon Fiber Products.

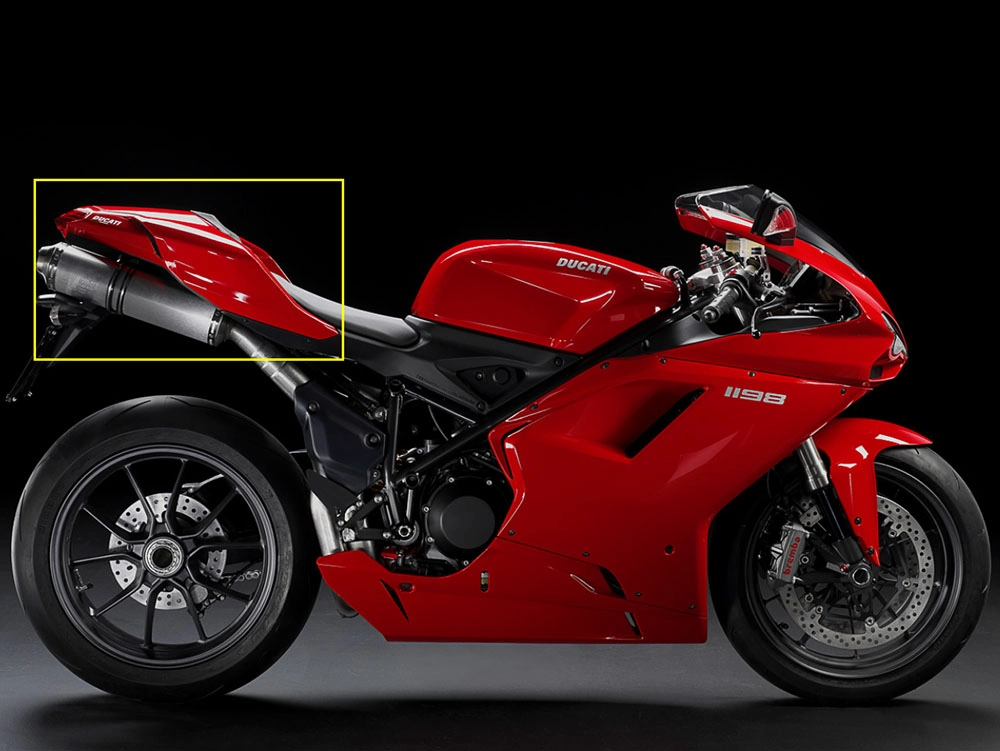

2025 Ducati Panigale V4/V4S Carbon Fiber Body Kit released by Supreem Carbon.

Лучший производитель углеродного волокна в Китае

Ducati monster 937 and BM S1000RR 2016+ new arrivals released!

Fabricante de fibra de carbono para motocicletas de alta calidad de China

For After-sales Service

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

For Facotry

How many employees of Supreem carbon?

We have over 50 employees, including over 40 skilled workers, 3 R&D designers, and 5 QC professionals and so on.

For Products

Are you parts have UV protected?

Absolutely! We use multiple layers of premium quality automotive clear (or matt) coats on our products, which ensure that they will remain super pretty for years to come.

BMW S1000RR Carbon Fiber Lower Side Fairings Custom

Yamaha MT-07 Carbon Fiber Tank Cover

Chevrolet Corvette C8 Carbon Fiber Bumper Trim Custom

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram