Benefits of Supreem Carbon Custom Sheets and Tubes

- Benefits of Supreem Carbon Custom Sheets and Tubes

- What are Carbon Fiber Sheets and Tubes?

- Product introduction: Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

- Core Advantages: Strength, Weight, and Stiffness

- Why strength-to-weight matters for your project

- Customization and Design Flexibility

- Design benefits of tailored layups

- Manufacturing Processes and What They Mean for Performance

- Performance Comparison: Carbon Fiber vs Metals

- Key Applications Across Industries

- Case example: automotive driveshaft

- Quality Assurance, Testing, and Standards

- Sustainability and Lifecycle Considerations

- Design and Machining Considerations

- Why Choose Supreem Carbon — Brand Advantages

- Cost Considerations and Value Analysis

- FAQ (Frequently Asked Questions)

- Q: What sizes and tolerances are available for Supreem Carbon custom sheets and tubes?

- Q: Are Supreem Carbon products suitable for structural aerospace use?

- Q: How do I decide between a sheet and a tube for my application?

- Q: What finishing options do you offer?

- Q: How long is the typical lead time?

- Contact and Next Steps

- Authoritative References

- References and Data Sources

- Final Call to Action

Benefits of Supreem Carbon Custom Sheets and Tubes

What are Carbon Fiber Sheets and Tubes?

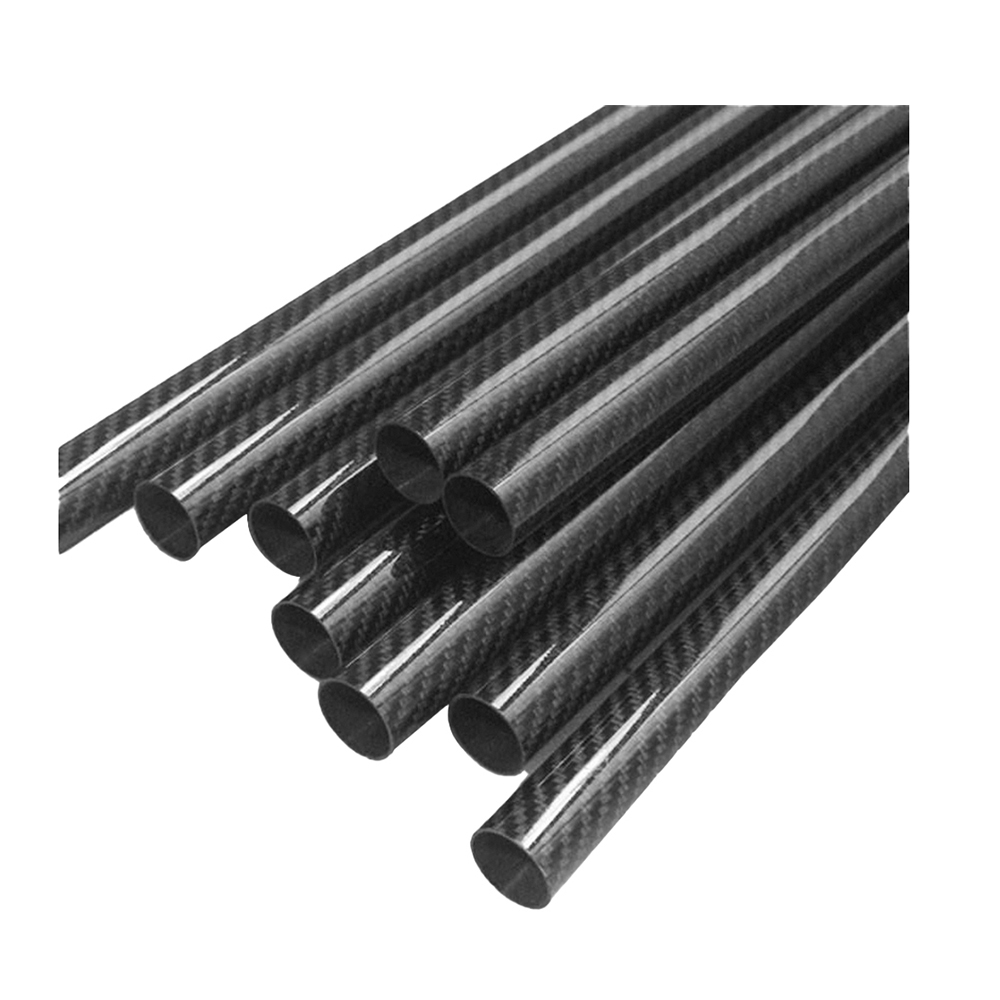

Carbon Fiber Sheets and Tubes are engineered composite components made from carbon fibers embedded in a polymer matrix. They combine high tensile strength, low weight, and corrosion resistance, enabling parts that outperform many metals in specific strength and stiffness. These materials are widely used where performance, precision, and longevity matter.

Product introduction: Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Core Advantages: Strength, Weight, and Stiffness

One of the primary benefits of Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes is their exceptional strength-to-weight ratio. Compared with conventional materials such as steel and aluminum, carbon fiber composites deliver equal or greater performance at a fraction of the mass. For designers, this translates directly to improved efficiency, faster acceleration in vehicles, greater payload capacity in aerospace, and easier handling for consumer equipment.

Why strength-to-weight matters for your project

Reducing mass while maintaining or improving structural performance impacts fuel efficiency, dynamic response, and operational costs. Supreem Carbon's custom layups allow you to orient fibers for load paths, tailoring stiffness where needed and saving weight elsewhere. The result is optimized parts rather than compromise designs.

Customization and Design Flexibility

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes are offered with extensive customization: fiber types (standard modulus, intermediate, high modulus), resin systems (epoxy, toughened epoxy, high-temp), layup patterns (unidirectional, woven, quasi-isotropic), and finishes (matte, glossy, protective coatings). Custom diameters, wall thicknesses, and flat sheet sizes are available to match engineering drawings and production needs.

Design benefits of tailored layups

Customized layups let engineers control directional stiffness and failure modes. For example, a unidirectional tube can be optimized for bending loads, whereas a quasi-isotropic sheet can be used where multi-directional strength is required. Supreem Carbon consults on layup choices to meet performance targets while controlling cost and manufacturability.

Manufacturing Processes and What They Mean for Performance

Supreem Carbon employs multiple manufacturing methods to produce sheets and tubes, each with distinct advantages:

- Prepreg layup and autoclave curing — highest fiber volume fraction and tight tolerances for aerospace-grade components.

- Resin transfer molding (RTM) — repeatable production with good surface finish for medium volumes.

- Filament winding — ideal for pultruded tubes with continuous fiber paths and excellent circumferential strength.

- Pultrusion — cost-effective for high-volume straight profiles with consistent cross-sections.

Choosing the right process affects mechanical properties, dimensional tolerances, cost, and lead time. Supreem Carbon advises customers on the optimal process for the application and volume.

Performance Comparison: Carbon Fiber vs Metals

The following table summarizes typical properties for carbon fiber composites versus aluminum and steel. Values are approximate and depend on specific material grades and processing.

| Property | Typical Carbon Fiber Composite | 6061-T6 Aluminum | A36 Steel |

|---|---|---|---|

| Density (g/cm³) | ~1.55 | 2.70 | 7.85 |

| Tensile strength (MPa) | 600–1200 (depending on fiber) | 290 | 400–550 |

| Young’s modulus (GPa) | 70–250 | 69 | 200 |

| Typical application benefit | High specific strength/stiffness, corrosion resistance | Lightweight metal, easy to machine | High toughness, cost-effective |

Source values vary with fiber type, matrix, and manufacturing process. For mission-critical applications, Supreem Carbon provides material certification and test data specific to the delivered batch.

Key Applications Across Industries

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes serve a broad range of markets:

- Automotive: lightweight body panels, driveshafts, structural braces, aerodynamic components that reduce mass and improve handling.

- Aerospace: interior panels, structural stiffeners, UAV airframes where weight and fatigue resistance are critical.

- Industrial: robotic arms, machine components, fixtures and jigs where precision and wear resistance extend service life.

- Consumer & Sports: high-performance sporting goods, camera rigs, bicycles, and audio equipment requiring stiffness and aesthetic finishes.

Supreem Carbon supports prototyping to full-scale production for each sector, aligning material choices and manufacturing routes with certification requirements.

Case example: automotive driveshaft

Replacing a steel or aluminum driveshaft with a carbon fiber tube can reduce rotational mass, improve vehicle responsiveness, and increase fatigue life. Supreem Carbon can supply balanced, precision-machined tubes that meet dynamic runout and concentricity specifications for drivetrain use.

Quality Assurance, Testing, and Standards

To meet engineering and regulatory requirements, Supreem Carbon applies rigorous QA and testing protocols including:

- Incoming fiber and resin material certification.

- Dimensional inspection using CMM and laser scanning.

- Mechanical testing: tensile, compression, flexural, interlaminar shear.

- Non-destructive inspection (NDI): ultrasonic C-scan, tap-testing, and thermography.

- Environmental and fatigue testing where required by customers.

Parts are delivered with test certificates and process traceability to support traceable supply chains and regulatory compliance.

Sustainability and Lifecycle Considerations

While carbon fiber production has higher upfront energy intensity than some metals, the lifecycle advantages—fuel savings, longer service life, and reduced maintenance—can deliver lower environmental impact over the part life for transportation and aerospace applications. Supreem Carbon works with customers on material selection and end-of-life strategies such as mechanical recycling or reuse of components where feasible.

Design and Machining Considerations

Designing with Carbon Fiber Sheets and Tubes differs from metals: you design the fiber path, not just the shape. Key considerations include:

- Fiber orientation for load paths.

- Allowances for ply drops and ply termination to avoid delamination.

- Tooling and fixturing for curing processes.

- Machining allowances—drilling, tapping, and CNC routing require special tooling and feeds to avoid fiber pull-out.

Supreem Carbon provides DFM (Design for Manufacturing) reviews, CNC machining services, and finishing (edge sealing, surface coating) to deliver ready-to-assemble components.

Why Choose Supreem Carbon — Brand Advantages

Supreem Carbon distinguishes itself in several ways:

- Custom engineering support: design reviews, layup simulation, and prototyping reduce risk and time-to-market.

- Wide process capability: prepreg/autoclave, RTM, filament winding, and pultrusion allow the right balance of performance and cost.

- Traceability and testing: batch-level certification and NDI reporting make Supreem Carbon suitable for safety-critical applications.

- Fast turnarounds: streamlined quoting and production workflows for both prototypes and production runs.

- Global material sourcing: access to high-performance fibers and resins to meet specialized requirements.

These advantages make Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes a reliable choice for engineers and procurement teams seeking performance with accountability.

Cost Considerations and Value Analysis

Carbon fiber components often have higher unit material costs than basic metals, but total cost of ownership (TCO) can favor composites when accounting for:

- Reduced operational costs (e.g., fuel savings).

- Lower maintenance and replacement frequency.

- Performance gains enabling new capabilities or higher value products.

Supreem Carbon offers cost-optimized layups and volume pricing to help customers find the right balance between performance and budget.

FAQ (Frequently Asked Questions)

Q: What sizes and tolerances are available for Supreem Carbon custom sheets and tubes?

A: Supreem Carbon offers a wide range of sheet sizes, thicknesses, tube diameters, and wall thicknesses. Typical dimensional tolerances depend on the manufacturing process: prepreg/autoclave parts can achieve tighter tolerances (±0.1–0.5 mm), while RTM and pultrusion have tolerances suited to their applications. Contact our engineering team for part-specific tolerance capabilities.

Q: Are Supreem Carbon products suitable for structural aerospace use?

A: Yes—Supreem Carbon can manufacture aerospace-grade components using qualified prepreg systems and autoclave curing, along with full material traceability, NDI reports, and certification documentation to meet customer and regulatory requirements.

Q: How do I decide between a sheet and a tube for my application?

A: Sheets are ideal for panels, skins, and machined parts, while tubes are suited to axles, spars, masts, and any application requiring high bending or torsional stiffness in a hollow section. Our engineers can review load cases to recommend the most efficient geometry.

Q: What finishing options do you offer?

A: Finishes include gelcoats, painted topcoats, clear coats, matte finishes, and protective edge treatments. For aesthetic applications, we can supply visible carbon weave finishes or painted surfaces to match brand colors.

Q: How long is the typical lead time?

A: Lead times depend on complexity and volume. Prototype parts can often be delivered in weeks; production runs depend on order size and process. Contact Supreem Carbon for a project-specific lead-time estimate.

Contact and Next Steps

Ready to specify Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes for your project? Contact our sales and engineering team to request a quote, submit drawings, or arrange material samples and test reports. View our product catalog and request custom quoting at: /products or email sales@supreemcarbon.example (replace with actual contact address).

Authoritative References

For further technical background, standards, and material data, see the authoritative sources below:

- Wikipedia — Carbon fiber

- ISO — Composites standards

- ASM International — Materials information

- MatWeb — Material Property Data

- SAE International — Aerospace and automotive standards

- CompositesWorld — Industry news and technical resources

References and Data Sources

Data and performance ranges included in this article are drawn from material property databases, industry handbooks, and composites technical resources listed above. For application-specific performance data and certified test reports, Supreem Carbon provides batch-level test certificates upon request.

Final Call to Action

If you have a specific design, upload your drawings or contact Supreem Carbon for a consultation: request a quote, ask for samples, or schedule a technical review. Our team will guide you to the best Carbon Fiber Sheets and Tubes solution for performance, cost, and manufacturability.

Custom carbon fiber motorcycle helmets Manufacturers and suppliers

What are the application scenarios of carbon fiber fishing pole?

Carbon Fiber Suppliers in China | Supreem Carbon

The Ultimate Guide to Custom Carbon Fiber Products: Everything You Need to Know

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

For After-sales Service

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

This carbon fiber rear seat panel is engineered for the BMW S1000R and M1000RR, offering superior rigidity, reduced weight, and a premium racing finish. Produced with autoclave technology and strict QC standards, the part ensures consistent OEM-level fitment. Supreem Carbon provides wholesale supply, stable bulk production, and customized solutions for global clients.

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Engineered for distributors, tuning brands, and motorcycle accessory businesses, the BMW S1000R Carbon Fiber Rear Undertail is a high-quality, durable, lightweight carbon fiber upgrade for the S1000R platform. This component is manufactured using aerospace-grade carbon fiber and precision molds to deliver superior stiffness, a seamless OEM-level fit, and a premium visual finish suitable for high-end aftermarket applications.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram