where can i buy carbon fiber sheets | Supreem Carbon Expert Guide

- Navigating the Purchase of Carbon Fiber Sheets: A Buyer's Guide

- Where are the best places to purchase carbon fiber sheets?

- What different types of carbon fiber sheets are available, and how do they differ?

- What factors influence the cost of carbon fiber sheets?

- What are the common applications for carbon fiber sheets, and how do they impact material choice?

- What key specifications should I consider when buying carbon fiber sheets for my project?

Navigating the Purchase of Carbon Fiber Sheets: A Buyer's Guide

Carbon fiber sheets have revolutionized industries from aerospace to automotive, sports equipment to robotics, due to their exceptional strength-to-weight ratio, stiffness, and aesthetic appeal. As the global carbon fiber market continues its robust growth – projected to exceed USD 10 billion by 2029 according to some market reports – understanding where and how to procure these advanced materials is crucial for engineers, manufacturers, and hobbyists alike. This guide aims to answer the most pressing questions for anyone looking to purchase carbon fiber sheets, ensuring an informed decision that meets project demands.

Where are the best places to purchase carbon fiber sheets?

The sourcing of carbon fiber sheets largely depends on your project's scale, budget, and quality requirements. Here are the primary avenues:

- Specialized Composites Suppliers: For professional-grade materials and technical support, suppliers like Fibre Glast Developments, Composites One, Rock West Composites, or McMaster-Carr are excellent choices. They offer a wide range of types, thicknesses, and weave patterns, often with detailed datasheets and quality certifications. These are ideal for industrial applications, prototyping, and high-performance projects.

- Online Marketplaces & Retailers: For smaller projects, hobbyists, or quick purchases, platforms like Amazon, eBay, or dedicated online composite material shops (e.g., Carbon Fiber Tube, Carbon Fiber Sheet Store) offer a convenient selection of pre-cut sheets. While accessible, verify seller reputation and product specifications carefully.

- Direct from Manufacturers: For large-volume orders, custom specifications, or highly specialized applications, direct engagement with carbon fiber manufacturers can provide competitive pricing and tailored solutions. Major global fiber producers include Toray Industries, Hexcel, and Teijin, though you'd typically buy sheets from fabricators using their fibers.

- Local Material Distributors: Some regions have local composite material distributors that can offer personalized service, immediate availability, and may cater to specific industry needs (e.g., marine or automotive composites).

What different types of carbon fiber sheets are available, and how do they differ?

Carbon fiber sheets come in various forms, each offering distinct properties and aesthetics:

- Weave Patterns:

- Twill Weave (e.g., 2x2 Twill): The most common and recognizable pattern, offering good drapability and a classic look. It's strong in multiple directions.

- Plain Weave: A tighter, symmetrical weave, offering high stability but less drapability than twill.

- Unidirectional (UD): Fibers run in a single direction, maximizing strength and stiffness along that axis. Ideal for applications requiring strength in one specific direction, like spars or beams.

- Satin Weave: A less common weave, offering a smoother surface and good drapability, often used for aesthetic finishes.

- Fiber Modulus: This refers to the stiffness of the carbon fiber filaments themselves. Higher modulus means greater stiffness.

- Standard Modulus (SM): E.g., Torayca T300, widely used, good balance of strength and cost.

- Intermediate Modulus (IM): E.g., Torayca T700, offering higher stiffness.

- High Modulus (HM) & Ultra High Modulus (UHM): Used in aerospace and high-performance applications where maximum stiffness is critical, but they come at a higher cost.

- Construction Method:

- Pre-preg Sheets: Carbon fiber fabric pre-impregnated with a precisely measured resin system (usually epoxy). They require heat and pressure (often in an autoclave) to cure, resulting in the highest strength-to-weight ratio and minimal void content, commonly used in aerospace (e.g., Boeing 787 uses over 50% composites by weight).

- Dry Fabric + Resin Infusion/Hand Layup: Users buy dry carbon fiber fabric and then infuse it with epoxy, vinyl ester, or polyester resin using vacuum bagging or hand layup techniques. More DIY-friendly but can result in higher void content and variable mechanical properties compared to pre-preg.

- Cured Carbon Fiber Plates/Panels: These are sheets that have already been manufactured and cured, ready for cutting, machining, and direct use. They are the most convenient for end-users, requiring no further curing process.

What factors influence the cost of carbon fiber sheets?

The price of carbon fiber sheets can vary significantly based on several factors:

- Thickness and Ply Count: Thicker sheets, composed of more layers (plies) of carbon fiber, naturally cost more due to increased material usage. Common thicknesses range from 0.25mm up to 6mm or more.

- Fiber Grade/Modulus: High-modulus fibers are more expensive due to their complex manufacturing process and superior stiffness.

- Weave Pattern and Finish: While subtle, certain complex weaves or specialized surface finishes (e.g., high-gloss, matte, polished) can slightly increase costs.

- Resin System and Curing Process: Pre-preg sheets cured in an autoclave (which provides optimal compaction and minimal voids) are generally more expensive than sheets made via wet layup or vacuum infusion processes, reflecting the higher manufacturing precision and equipment costs.

- Raw Material Costs: The price of polyacrylonitrile (PAN), the primary precursor for most carbon fiber, and petroleum-based resins (like epoxy) directly impacts final product cost, making the industry susceptible to global commodity price fluctuations.

- Quantity Purchased: Bulk orders typically qualify for significant per-unit discounts compared to small, one-off purchases.

- Customization: Custom dimensions, specific layups, or unique finishes will incur higher costs due to specialized production runs.

What are the common applications for carbon fiber sheets, and how do they impact material choice?

Carbon fiber's versatility means it's used across a multitude of sectors, with specific applications driving material selection:

- Aerospace & Defense: Used for aircraft structures (e.g., fuselage, wings, tail sections of the Boeing 787), missiles, and satellites. Requires high strength-to-weight, stiffness (often HM/UHM fibers), fatigue resistance, and temperature stability. Pre-preg materials and autoclave curing are standard for these critical applications.

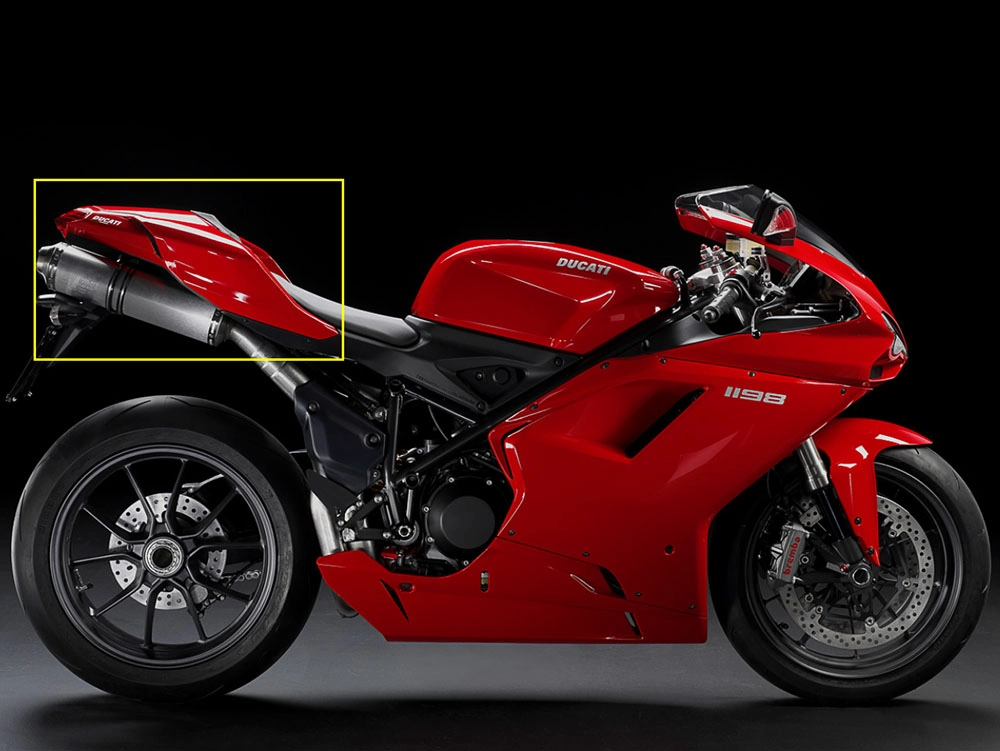

- Automotive: Found in high-performance sports cars (chassis, body panels, interior trims), motorsport (F1 components), and increasingly in electric vehicles for weight reduction and increased range. Balance of strength, stiffness, impact resistance, and aesthetics (often 2x2 twill) is key.

- Sports & Leisure: Widely used in bicycles, tennis rackets, golf clubs, fishing rods, skis, and marine vessels (hulls, masts). Emphasis on lightweight, stiffness, and durability. Specific weave patterns and fiber orientations are chosen to optimize performance for different types of athletic impact or flex.

- Industrial & Robotics: For robotic arms, drone frames, X-ray equipment, and specialized machinery components. Focus on lightweight for faster movement, precision, and vibration damping.

- Medical: Used in prosthetic limbs, surgical instruments, and MRI tables due to its X-ray transparency and strength.

The application dictates the necessary mechanical properties (tensile strength, compressive strength, modulus), environmental resistance (UV, chemical, temperature), and even aesthetic requirements, all of which inform the choice of fiber type, weave, resin, and manufacturing process.

What key specifications should I consider when buying carbon fiber sheets for my project?

Making an informed purchase requires evaluating several critical specifications:

- Dimensions & Thickness: Crucial for fit and structural integrity. Ensure the sheet dimensions (length x width) meet your needs, and the thickness (often expressed in millimeters or as ply count) provides sufficient strength for the intended load.

- Fiber Type & Modulus: Match the fiber's stiffness (standard, intermediate, high modulus) to your project's stiffness requirements. For instance, a drone frame might use a good balance of strength and stiffness (e.g., T700 equivalent), while a satellite component might demand ultra-high modulus.

- Resin System: Most carbon fiber sheets are epoxy-based due to superior mechanical properties and chemical resistance. For marine applications, vinyl ester might be considered for better water resistance.

- Weave Pattern & Finish: Beyond aesthetics, weave can slightly influence properties and machinability. A 2x2 twill offers good all-around performance and a classic look, while plain weave is very stable. Consider if you need a high-gloss, matte, or textured (e.g., peel ply) finish for subsequent bonding or painting.

- Temperature & Chemical Resistance: If the part will be exposed to extreme temperatures or harsh chemicals, ensure the resin system is rated for those conditions.

- UV Stability: For outdoor applications, UV-resistant clear coats or resins are essential to prevent degradation over time.

- Quality Standards & Tolerances: For critical applications (e.g., aerospace), verify that the material meets specific industry standards (e.g., ASTM, aerospace grade certifications) and comes with tight thickness tolerances and low void content.

Understanding these aspects will empower you to select the right carbon fiber sheets, ensuring optimal performance and cost-effectiveness for your project.

Supreem Carbon Advantage: Precision, Performance, and Purity

When it comes to sourcing top-tier carbon fiber sheets, Supreem Carbon stands out as a premier choice. Our commitment to excellence is reflected in our meticulous manufacturing processes, primarily utilizing high-pressure, high-temperature autoclave curing. This advanced technique ensures minimal void content, yielding sheets with superior mechanical properties, unparalleled strength-to-weight ratios, and exceptional durability, making them ideal for the most demanding applications.

Supreem Carbon uses only the highest quality carbon fiber raw materials, guaranteeing consistent performance across our diverse product range. We offer a comprehensive selection of weave patterns, thicknesses, and fiber modulus options to cater to a wide array of industrial, automotive, aerospace, and sports applications. Our stringent quality control measures ensure every sheet meets precise specifications, providing you with reliable and repeatable results. With Supreem Carbon, you gain access to custom solutions, competitive pricing without compromising quality, and dedicated technical support, ensuring your project achieves its full potential.

How Long Does Carbon Fiber Last? Unveiling the Durability of a Tech Marvel

Fabricante de fibra de carbono para motocicletas de alta calidad de China

What Are the Most Common Uses of Carbon Fiber in 2025?

New arrivals- BMW CSL style carbon fiber front grille released by Supreem carbon!!

Supreem Carbon new engine cover released!

Supreem Carbon New Motorcycle Carbon Parts Development Plan.

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

For Facotry

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

For Products

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

Yamaha MT-07 Carbon Fiber Tank Cover

Kawasaki Z650 Carbon Fiber Tank Side Panels

Kawasaki ZX10R Carbon Fiber Belly Pan

The carbon fiber belly pan reduces the weight of the car body and provides a unique visual effect. It improves motorcycle performance and provides an excellent driving experience. It is handmade with 100% dry carbon technology and perfectly matches the original car accessories. You can replace the ABS directly.

Supreem Carbon Custom Carbon Fiber Airbox Cover for Honda CBR1000RR-R

This carbon fiber tank cover can directly replace the ABS part, giving your CBR1000RR-R a fantastic and unique carbon fiber look.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram