Carbon Fiber Producers: Your Guide

- Finding the Right Carbon Fiber Producers: A Comprehensive Guide

- What are the Different Types of Carbon Fiber?

- Where Can I Find Reliable Carbon Fiber Producers?

- What Factors Should I Consider When Choosing a Carbon Fiber Producer?

- What are the Key Applications of Carbon Fiber?

- How Can I Ensure the Quality of Carbon Fiber I Purchase?

Finding the Right Carbon Fiber Producers: A Comprehensive Guide

The carbon fiber industry is booming, with applications spanning aerospace, automotive, sports equipment, and more. Selecting the right carbon fiber producer is crucial for project success. This guide addresses key questions to help you make informed decisions.

What are the Different Types of Carbon Fiber?

* High Modulus Carbon Fiber: Known for its exceptional stiffness and strength-to-weight ratio. Ideal for high-performance applications like aerospace and Formula 1 racing. Manufacturers often specify the modulus (e.g., IM7, IM8, T1000G) to indicate its stiffness.

* High Tensile Carbon Fiber: This type prioritizes tensile strength, making it suitable for applications requiring high load-bearing capacity, such as bridges or large-scale structures.

* Standard Modulus Carbon Fiber: A balance between strength, stiffness, and cost-effectiveness. Commonly used in a wider range of applications, including sporting goods and automotive parts.

Where Can I Find Reliable Carbon Fiber Producers?

Sourcing carbon fiber involves careful consideration. Here are some avenues:

* Online Directories: Industry-specific online directories list carbon fiber manufacturers, often providing detailed company profiles and contact information.

* Trade Shows and Conferences: These events provide a great opportunity to network with producers, see products firsthand, and gather detailed information. Events like JEC World are key industry gatherings.

* Industry Associations: Associations like the American Carbon Fiber Manufacturers Association (though the name may vary by region) often have member directories that can help you find reputable suppliers.

* Direct Supplier Search: Use online search engines and focus on geographic location or specific fiber types to narrow your results.

What Factors Should I Consider When Choosing a Carbon Fiber Producer?

Several key factors influence your choice:

* Quality Certification: Look for certifications like ISO 9001 (quality management) to ensure consistent product quality.

* Production Capacity: Ensure the producer can meet your volume requirements and delivery deadlines.

* Price and Cost-Effectiveness: Balance quality with budget constraints. Get quotes from multiple producers to compare pricing.

* Technical Support and Expertise: Consider the producer's ability to provide technical assistance, especially for complex projects.

* Location and Logistics: Evaluate proximity to your manufacturing facility for ease of supply chain management.

What are the Key Applications of Carbon Fiber?

Carbon fiber's versatility fuels its use across numerous sectors:

* Aerospace: Aircraft components, satellites, and rockets benefit from carbon fiber's lightweight and high-strength properties.

* Automotive: Increased fuel efficiency and improved performance in cars and other vehicles.

* Sports and Recreation: Golf clubs, bicycles, fishing rods, and other sporting equipment use carbon fiber for improved performance.

* Construction: Reinforcement in concrete, bridges, and other structures for increased strength and durability.

* Medical: Prosthetic limbs, surgical instruments, and medical implants.

How Can I Ensure the Quality of Carbon Fiber I Purchase?

* Request Material Testing Reports: Verify the fiber's properties against your project specifications.

* Conduct Independent Testing: If necessary, send samples to an independent testing laboratory for verification.

* Review Supplier's Quality Control Procedures: Understand their quality assurance measures.

This guide provides a starting point for your search for the right carbon fiber producer. Remember, thorough research and due diligence are crucial for a successful outcome. Contact Supreem Carbon to discuss your specific needs and explore our range of high-quality carbon fiber products and services.

Carbon Fibre Custom Made Parts for Your Project Car

Custom carbon fiber cars Manufacturers and Suppliers

The Ultimate Guide to Motorcycle Carbon Fiber Accessories | Supreem Carbon

Enhance Your Ride with a Custom Steering Wheel Carbon Fiber Upgrade from Supreem Carbon

For Products

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

Are you parts have UV protected?

Absolutely! We use multiple layers of premium quality automotive clear (or matt) coats on our products, which ensure that they will remain super pretty for years to come.

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

For After-sales Service

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

BMW F85/ F86 Carbon Fiber Interior Engine Cover Replacement

Crafted with precision, this BMW carbon fiber accessory combines perfect fitment with superior UV protection and clearcoat finishing. Ideal for OEM-quality upgrades and custom builds.

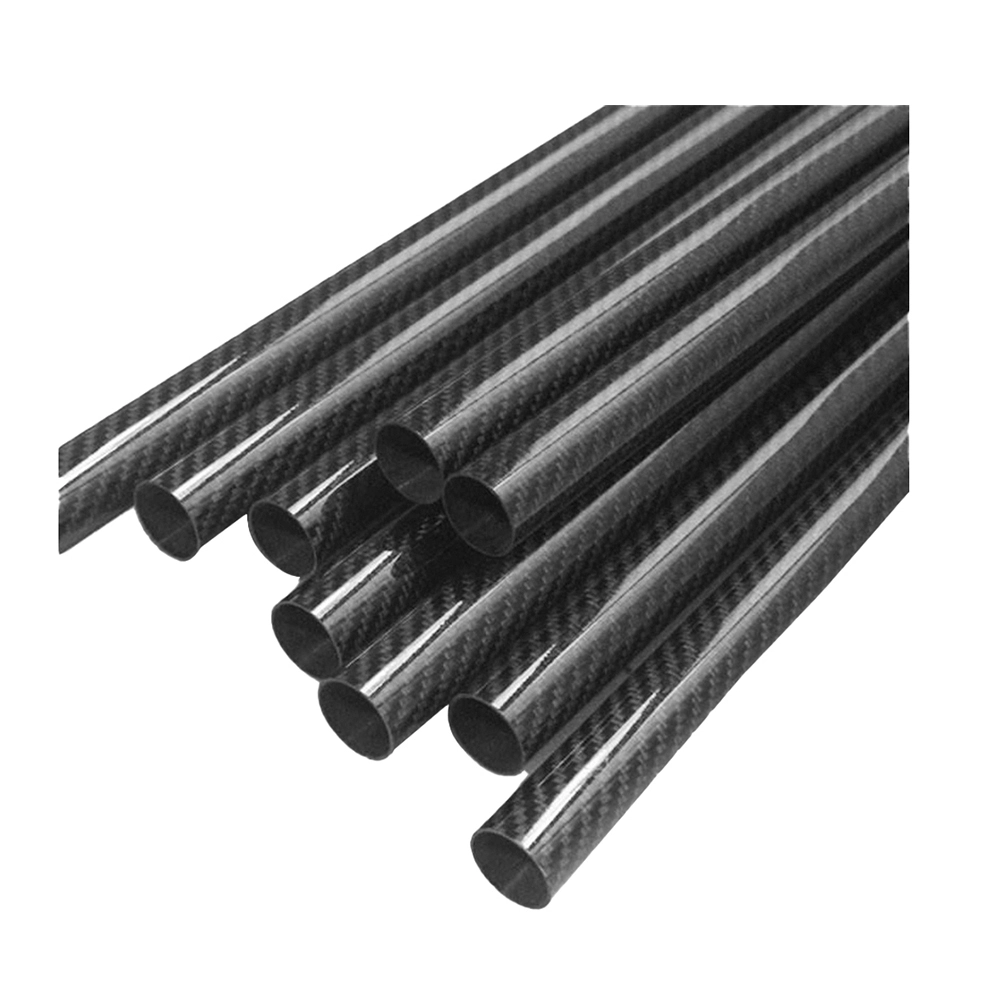

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram