How does manufacturing differ for dry carbon vs wet carbon? | Insights by Supreem Carbon

In the realm of carbon fiber parts manufacturing, understanding the differences between dry and wet carbon processes is crucial for making informed procurement decisions. These methods significantly influence the quality, performance, and cost of the final product.

Dry Carbon Fiber Manufacturing

Dry carbon fiber manufacturing involves the use of pre-impregnated carbon fiber sheets, known as prepregs, which are pre-impregnated with resin. This process offers several advantages:

Enhanced Quality Control: Prepregs provide consistent resin content and fiber alignment, resulting in parts with superior mechanical properties.

Reduced Labor Intensity: The automated nature of prepreg lay-up reduces manual labor and the potential for human error.

Superior Surface Finish: The controlled resin application leads to smoother surfaces, reducing the need for extensive post-processing.

However, this method also presents challenges:

Storage and Handling Requirements: Prepregs require refrigerated storage to maintain resin stability, which can increase operational costs.

Limited Shelf Life: The resin in prepregs has a finite shelf life, necessitating careful inventory management.

Higher Material Costs: The advanced technology and materials involved contribute to higher costs compared to wet lay-up methods.

Wet Carbon Fiber Manufacturing

Wet carbon fiber manufacturing, or hand lay-up, involves manually applying resin to dry carbon fiber sheets. This traditional method offers:

Flexibility: Suitable for low-volume and custom parts, allowing for design modifications without significant cost increases.

Lower Initial Investment: The equipment and setup costs are generally lower, making it accessible for small-scale operations.

However, it also has drawbacks:

Inconsistent Quality: Manual application can lead to variations in resin distribution and fiber alignment, affecting part strength and durability.

Labor-Intensive Process: The reliance on manual labor increases the potential for human error and can lead to higher labor costs.

Surface Imperfections: Achieving a smooth surface finish may require additional post-processing steps.

Key Considerations for Procurement

When sourcing carbon fiber parts, consider the following:

Quality Assurance: Ensure suppliers implement rigorous quality control measures, including material testing and inspection protocols.

Supplier Certifications: Look for certifications such as ISO 9001, indicating adherence to quality management standards.

Customization Capabilities: Assess the supplier's ability to meet specific design requirements and provide customization options.

Lead Times and Minimum Order Quantities (MOQs): Discuss production timelines and order sizes to align with project needs.

Cost Implications: Evaluate the cost-effectiveness of the manufacturing method in relation to the desired part performance and quality.

Supreem Carbon's Advantages

Supreem Carbon stands out in the carbon fiber industry by offering:

High-Quality Manufacturing: Utilizing advanced techniques to produce parts with superior mechanical properties and surface finishes.

Customization Expertise: Providing tailored solutions to meet specific client requirements across various industries.

Efficient Lead Times: Ensuring timely delivery without compromising on quality, supported by streamlined production processes.

Competitive Pricing: Offering cost-effective solutions without sacrificing performance, making high-quality carbon fiber parts accessible.

By understanding the distinctions between dry and wet carbon fiber manufacturing, procurement professionals can make informed decisions that align with their project's technical and budgetary requirements.

Data Sources:

Supreem Carbon's Manufacturing Processes and Procurement Guide

Carbon Fiber Parts Manufacturing: Global Supplier Guide & Selection Tips

Definitive Guide to Carbon Fiber Material Prices

Your Ultimate Guide to Sourcing Carbon Fiber Material Kit

China Carbon Fiber: An In-Depth Procurement Guide

Carbon Fiber's Uniqueness: A B2B Procurement Guide

Carbon Fiber as a Composite: Industrial Procurement Guide

Custom Carbon Fiber Parts: The Ultimate Buyer’s Guide

By leveraging this knowledge, you can enhance your procurement strategy and ensure the acquisition of high-quality carbon fiber components that meet your project's specific needs.

Carbon Fiber in Everyday Products: Modern Applications & Home Uses | Supreem Carbon

2025 Ducati Panigale V4/V4S Carbon Fiber Body Kit released by Supreem Carbon.

Aprilia Tuono V4 2021 new arrivals.

How Long Do Carbon Fiber Parts Last? | Supreem Carbon

Ducati monster 937 and BM S1000RR 2016+ new arrivals released!

New arrivals---Carbon Fiber Slam Panel Replacement for BMW M3 M4

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

For Facotry

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

For Customized Service

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

What custom customer need to prepare?

1. Send Your Design/Idea/3D drawing.

2. Supplier Quotation Confirmation.

3. Firts Sample Feedback.

For Products

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

Honda NSX Carbon Fiber Center Dash Panel Replacement

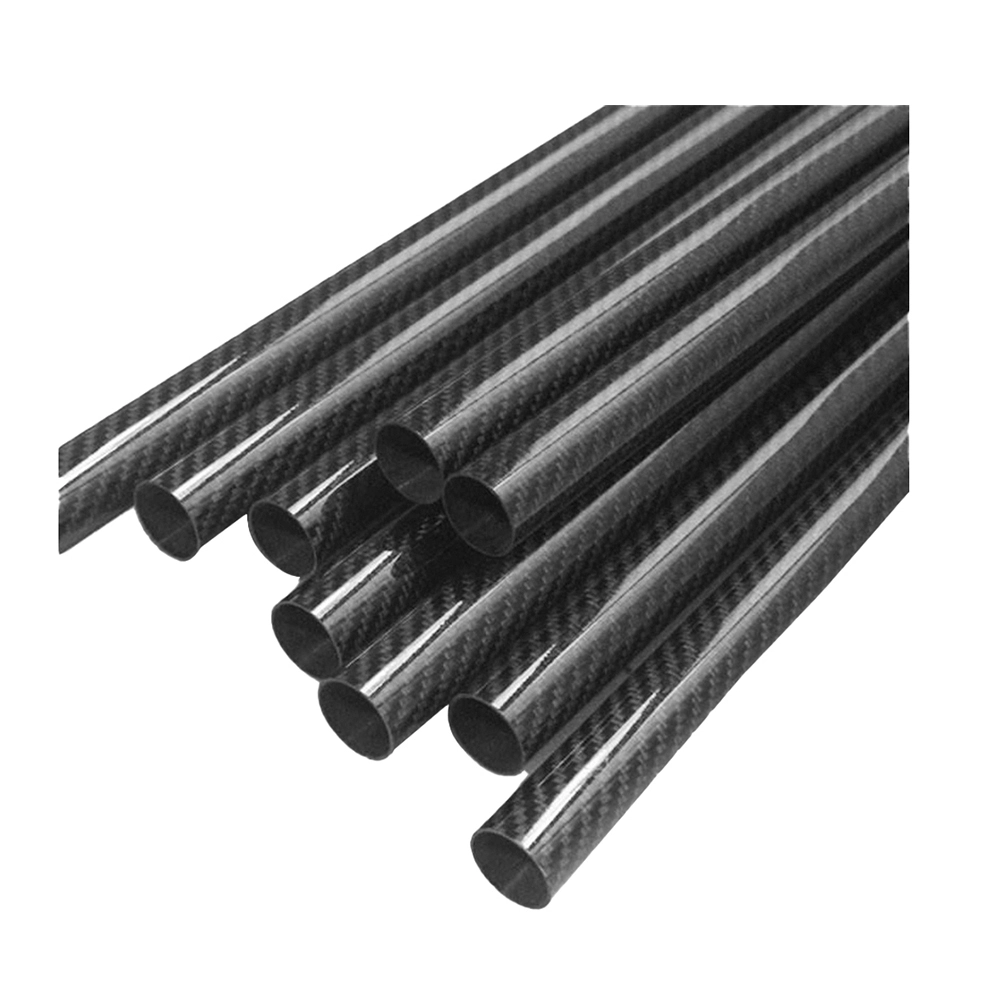

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Aprilia Tuono V4 Carbon Fiber Exhaust Cover

Ducati Panigale/Streetfighter V4 Carbon Fiber Heel Guards

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram