How can custom carbon fiber parts reduce product weight?

- What Are the Advantages of Using Custom Carbon Fiber Parts?

- How Do Custom Carbon Fiber Parts Reduce Product Weight?

- What Are the Cost Implications of Custom Carbon Fiber Parts?

- What Manufacturing Processes Are Used for Custom Carbon Fiber Parts?

- How Do Custom Carbon Fiber Parts Enhance Product Performance?

- What Are the Durability and Maintenance Considerations for Carbon Fiber Parts?

- How Do I Choose a Reliable Supplier for Custom Carbon Fiber Parts?

- Conclusion

- About Supreem Carbon

Custom carbon fiber parts have become a popular choice in various industries due to their unique combination of strength, lightweight properties, and aesthetic appeal. This article addresses common questions and provides essential information for professionals considering the procurement of custom carbon fiber components.

What Are the Advantages of Using Custom Carbon Fiber Parts?

Custom carbon fiber parts offer several benefits:

Lightweight Construction: Carbon fiber components are significantly lighter than traditional materials like steel and aluminum, leading to improved performance and fuel efficiency.

Exceptional Strength and Durability: Despite their lightness, carbon fiber parts possess high tensile strength and resistance to corrosion, enhancing the longevity and safety of products.

Design Flexibility: The malleability of carbon fiber allows for complex and customized designs, enabling parts to be tailored to specific performance requirements and aesthetic preferences.

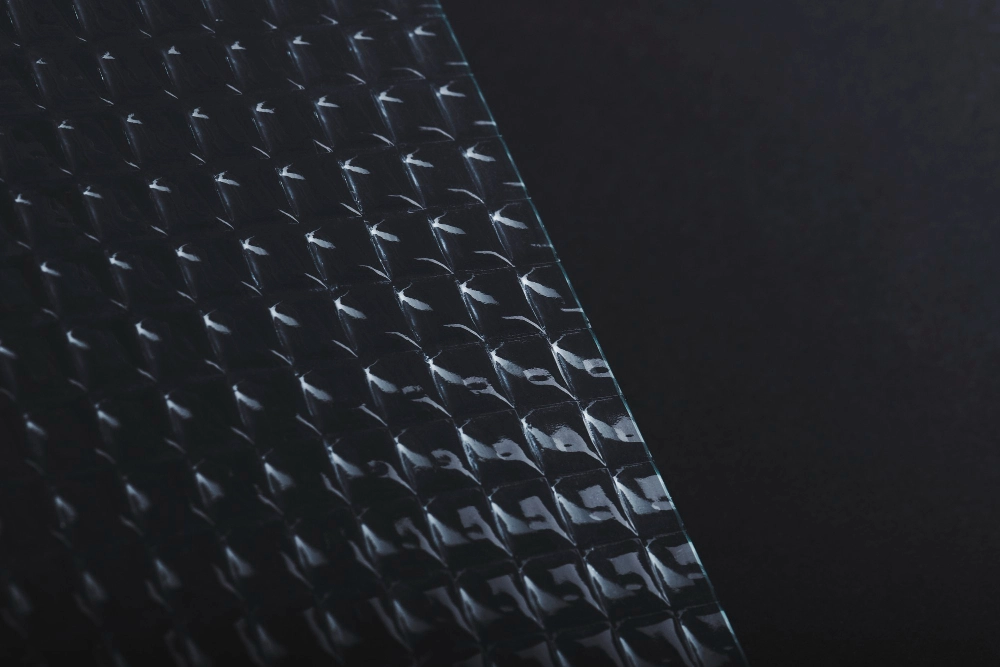

Enhanced Aesthetics: The distinctive weave pattern of carbon fiber imparts a modern, high-tech appearance, adding visual appeal to products.

How Do Custom Carbon Fiber Parts Reduce Product Weight?

The lightweight nature of carbon fiber is due to its low density and high strength-to-weight ratio. By substituting heavier materials with carbon fiber, manufacturers can significantly reduce the overall weight of a product. This reduction leads to improved acceleration, handling, and fuel efficiency in vehicles, and enhanced performance in other applications.

What Are the Cost Implications of Custom Carbon Fiber Parts?

Custom carbon fiber parts generally come with a higher upfront cost compared to traditional materials. This is due to the expense of raw materials and the specialized manufacturing processes required. However, the investment can be justified by the performance enhancements, durability, and potential for weight reduction, which can lead to long-term savings and increased product value. ((https://www.supreemcarbon.com/are-carbon-fiber-parts-worth-cost.html))

What Manufacturing Processes Are Used for Custom Carbon Fiber Parts?

Several manufacturing techniques are employed to produce custom carbon fiber parts:

Hand Lay-Up: A manual process where carbon fiber sheets are layered and impregnated with resin, suitable for large parts like body panels.

Resin Transfer Molding (RTM): Involves injecting resin into a mold containing carbon fiber fabric, offering better control over material distribution and part quality.

Autoclave Molding: Utilizes high pressure and temperature in an autoclave to cure the resin, resulting in parts with superior strength and surface finish.

Prepreg Lamination: Employs pre-impregnated carbon fiber sheets that are cured under heat and pressure, allowing for complex and precise part designs.

How Do Custom Carbon Fiber Parts Enhance Product Performance?

By reducing weight and increasing strength, custom carbon fiber parts can significantly improve product performance. In automotive applications, lighter vehicles experience better acceleration, handling, and fuel efficiency. In aerospace, reduced weight leads to increased payload capacity and fuel savings. Additionally, the stiffness of carbon fiber components can enhance structural integrity and responsiveness.

What Are the Durability and Maintenance Considerations for Carbon Fiber Parts?

Carbon fiber parts are known for their durability and resistance to corrosion, which contributes to a longer service life. However, they can be susceptible to damage from UV exposure and extreme temperatures. Proper coating and maintenance are essential to protect the material and ensure optimal performance.

How Do I Choose a Reliable Supplier for Custom Carbon Fiber Parts?

When selecting a supplier, consider the following factors:

Experience and Expertise: Look for manufacturers with a proven track record in producing high-quality carbon fiber components.

Customization Capabilities: Ensure the supplier can meet your specific design and performance requirements.

Quality Control: Verify that the supplier implements rigorous quality assurance processes to maintain product standards.

Customer Support: Assess the level of after-sales support and responsiveness to inquiries. ((https://www.supreemcarbon.com/top-benefits-custom-carbon-fiber-parts-vehicles.html))

Conclusion

Custom carbon fiber parts offer significant advantages in terms of weight reduction, strength, and design flexibility, leading to enhanced product performance and aesthetics. While they may involve higher initial costs, the long-term benefits often justify the investment. By understanding the manufacturing processes and selecting a reputable supplier, businesses can effectively incorporate carbon fiber components into their products.

About Supreem Carbon

Supreem Carbon, established in 2017, specializes in the customized manufacturing of carbon fiber parts for cars and motorcycles. With a factory spanning approximately 4,500 square meters and a skilled team of 45 production and technical staff, Supreem Carbon offers over 1,000 product types, including more than 500 customized carbon fiber parts. The company focuses on delivering high-quality, reliable components that meet both performance and aesthetic goals. ((https://www.supreemcarbon.com/top-benefits-custom-carbon-fiber-parts-vehicles.html))

For more information or to explore our range of custom carbon fiber parts, visit (https://www.supreemcarbon.com/).

How Long Do Carbon Fiber Parts Last? | Supreem Carbon

Carbon Fiber Helmet produced by Supreem Carbon.

New arrivals---Carbon Fiber Slam Panel Replacement for BMW M3 M4

Best 10 Carbon Fiber Parts Manufacturers in 2026: Industry Leaders Ranked

Rev Up Your Ride: Supreem Carbon - China's Finest Custom Motorcycle Carbon Fiber Parts

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

For Facotry

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

For After-sales Service

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

For Products

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

Custom Carbon Fiber Watch

Carbon fiber is becoming a preferred material in the watch industry thanks to its exceptional strength, lightweight structure, and modern aesthetic. Its advanced performance properties make it ideal for producing durable, high-precision watch components.

BMW M2 M3 Carbon Fiber Engine Cover Replacement

Volkswagen Golf R Mk8 Carbon Fiber Front Bumper Surrounds

We are committed to providing customers with the highest quality aerodynamic kits, just like this Volkswagen front bumper surround, which gives you a different visual experience. Not only are our products lighter than ABS, but they are also corrosion-resistant and have a UV-protective coating. 100% handmade, dry carbon autoclave process. It can directly replace original vehicle parts.

Honda NSX Carbon Fiber Interior Door Handles Replacement

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram