Are carbon fiber composites recyclable and sustainable in aerospace? | Insights by Supreem Carbon

- 1. What are the environmental impacts of carbon fiber composites in aerospace?

- 2. How recyclable are carbon fiber composites used in aerospace?

- 3. What are the economic implications of recycling carbon fiber composites?

- 4. How do carbon fiber composites compare to other materials in terms of sustainability?

- 5. What advancements are being made in recycling technologies for carbon fiber composites?

- 6. What are the challenges in implementing recycling processes for carbon fiber composites in aerospace?

- 7. How can procurement professionals address sustainability concerns when sourcing carbon fiber composites?

- 8. What is the future outlook for the recyclability and sustainability of carbon fiber composites in aerospace?

- Supreem Carbon's Advantages

- Data Sources

1. What are the environmental impacts of carbon fiber composites in aerospace?

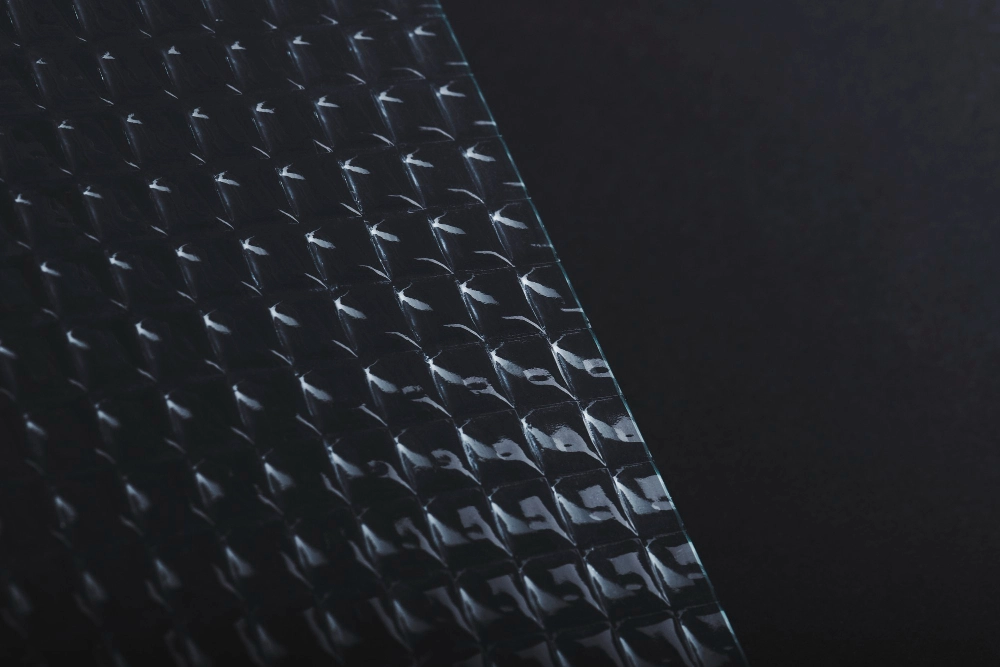

Carbon fiber composites (CFCs) offer significant advantages in aerospace applications, such as high strength-to-weight ratios and corrosion resistance. However, their environmental impact is a growing concern. The production of virgin carbon fiber is energy-intensive and costly, leading to a substantial carbon footprint. Additionally, the disposal of CFCs poses challenges due to their durability and resistance to natural degradation, contributing to landfill accumulation.

2. How recyclable are carbon fiber composites used in aerospace?

Recycling carbon fiber composites is complex due to their robust nature. Traditional mechanical recycling methods, like shredding, often result in reduced mechanical properties of the recycled fibers. Advanced techniques, such as pyrolysis and solvolysis, have been developed to recover fibers with properties closer to those of virgin materials. For instance, a team of scientists from three Chinese universities developed a recyclable carbon fiber-reinforced epoxy composite that maintains mechanical strength and durability, demonstrating the potential for effective recycling in aerospace applications.

3. What are the economic implications of recycling carbon fiber composites?

The economic viability of recycling carbon fiber composites is influenced by factors such as the cost of recycling technologies, the quality of recycled fibers, and market demand. While recycling can reduce material costs and environmental impact, the initial investment in advanced recycling facilities and processes can be substantial. However, as demand for sustainable materials increases and recycling technologies advance, the economic feasibility of recycling CFCs is expected to improve.

4. How do carbon fiber composites compare to other materials in terms of sustainability?

Compared to traditional materials like aluminum, carbon fiber composites offer superior strength-to-weight ratios, leading to fuel efficiency and reduced emissions in aerospace applications. However, the sustainability of CFCs is compromised by challenges in recycling and the environmental impact of their production. Ongoing research aims to develop more sustainable production methods and improve recycling processes to enhance the overall sustainability of CFCs.

5. What advancements are being made in recycling technologies for carbon fiber composites?

Significant progress is being made in developing recycling technologies for carbon fiber composites. For example, Uplift360, an international chemical recycling company, has developed a proprietary chemical process that dissolves and re-spins para-aramid fibers into continuous, high-performance fibers, demonstrating the potential for recycling composite materials.

6. What are the challenges in implementing recycling processes for carbon fiber composites in aerospace?

Implementing recycling processes for carbon fiber composites in aerospace faces several challenges, including the need for specialized recycling facilities, the high cost of advanced recycling technologies, and the variability in composite materials used across different aircraft. Additionally, ensuring the quality and consistency of recycled fibers to meet aerospace standards is a critical concern.

7. How can procurement professionals address sustainability concerns when sourcing carbon fiber composites?

Procurement professionals can address sustainability concerns by collaborating with suppliers who prioritize sustainable practices, investing in technologies that enhance the recyclability of carbon fiber composites, and considering the entire lifecycle impact of materials. Engaging in industry initiatives focused on sustainability and staying informed about advancements in recycling technologies can also support more sustainable sourcing decisions.

8. What is the future outlook for the recyclability and sustainability of carbon fiber composites in aerospace?

The future outlook for the recyclability and sustainability of carbon fiber composites in aerospace is promising, with ongoing research and technological advancements aimed at improving recycling processes and reducing environmental impact. As these technologies mature and become more cost-effective, the adoption of sustainable practices in the aerospace industry is expected to increase, leading to more environmentally friendly and economically viable use of carbon fiber composites.

Supreem Carbon's Advantages

Supreem Carbon stands at the forefront of sustainable aerospace materials, offering advanced carbon fiber composites that are engineered for recyclability and high performance. Our commitment to innovation ensures that our products not only meet the stringent demands of the aerospace industry but also contribute to environmental conservation efforts. By choosing Supreem Carbon, procurement professionals can access cutting-edge materials that align with sustainability goals without compromising on quality or performance.

Data Sources

- Wikipedia: "Aircraft Recycling". Last modified: October 2025.

- Wikipedia: "Carbon Fibers". Last modified: October 2025.

- Wikipedia: "Toray Advanced Composites". Last modified: September 2025.

- Wikipedia: "Hy-Bor". Last modified: October 2025.

- Wikipedia: "Lamborghini Lab". Last modified: October 2025.

- Wikipedia: "Hexcel". Last modified: October 2025.

- Wikipedia: "Firm | SBIR". Last modified: November 2025.

- Wikipedia: "Recyclable Composites | ecobees.in". Last modified: November 2025.

- Wikipedia: "Uplift360 transforms composite waste into high-quality aramid fibers continuously". Last modified: November 2025.

- Wikipedia: "Recyclable Composites | ecobees.in". Last modified: November 2025.

- Wikipedia: "Recyclable Composites | ecobees.in". Last modified: November 2025.

Lamborghini Urus engine compartment carbon fiber kit released by Supreem Carbon.

Supreem Carbon: Asya'nın En İyi Profesyonel Motosiklet Karbon Fiber Üretici Markası

Carbon Fiber Helmet produced by Supreem Carbon.

New Arrivals of BMW S1000RR 2020+ full carbon fiber sets.

Supreem carbon new carbon fiber engine cover for GR Yaris.

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

For Products

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

Ducati Panigale/Streetfighter V4 Carbon Fiber Heel Guards

Honda CBR1000RR-R Carbon Fiber Airbox Cover Custom

Aprilia Tuono V4 Carbon Fiber Exhaust Cover

Carbon Fiber Wine Bracket Custom

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram