Supreem Carbon: Expert Carbon Fiber Accessory Suppliers

Discover the expertise of Supreem Carbon, your premier supplier of various types of carbon fiber accessories. Established in 2017, Supreem Carbon has quickly become a leader in the customized manufacturing of carbon fiber automobile and motorcycle parts. By integrating research and development, design, production, and sales, we guarantee high-quality services and products that exceed your expectations.

Our dedication to innovation is evident in our robust technology research and development for carbon fiber composite products. Whether you're looking to enhance your vehicle with customized and modified carbon fiber automobile and motorcycle accessories or seeking High Quality carbon fiber home luggage and sports equipment, Supreem Carbon has you covered.

With a sprawling factory space of 4,500 square meters, equipped with a skilled workshop production team and technical staff of 45 professionals, we prioritize excellence in every piece. Our impressive annual output value of approximately $4 million speaks volumes about our commitment and capability.

Supplying over 1,000 distinct carbon fiber products, we proudly cater to both customized and standard demands, ensuring that every client feels valued and receives tailored solutions. Let Supreem Carbon be your trusted partner in superior carbon fiber craftsmanship, where practicality meets elegance, and consumers come first.

Detailed display

Our Advantages

After-sales support

The professional after-sales team can quickly solve some problems that customers have during product use and provide corresponding solutions.

Rich R&D Experience

Our R&D team members are all professional and technical personnel who have been working in the carbon fiber industry for more than 10 years. We can understand customer needs as soon as possible and provide development technical support.

Free samples

For specific product development projects, we will provide customers with a set of free samples.

Project consultation

Our designers will provide customers with project feasibility analysis and quotations based on the ideas and design concepts or drawings provided by customers.

Frequently Asked Questions

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

Ducati Monster 821 797 1200 937 Carbon Fiber Front Fender

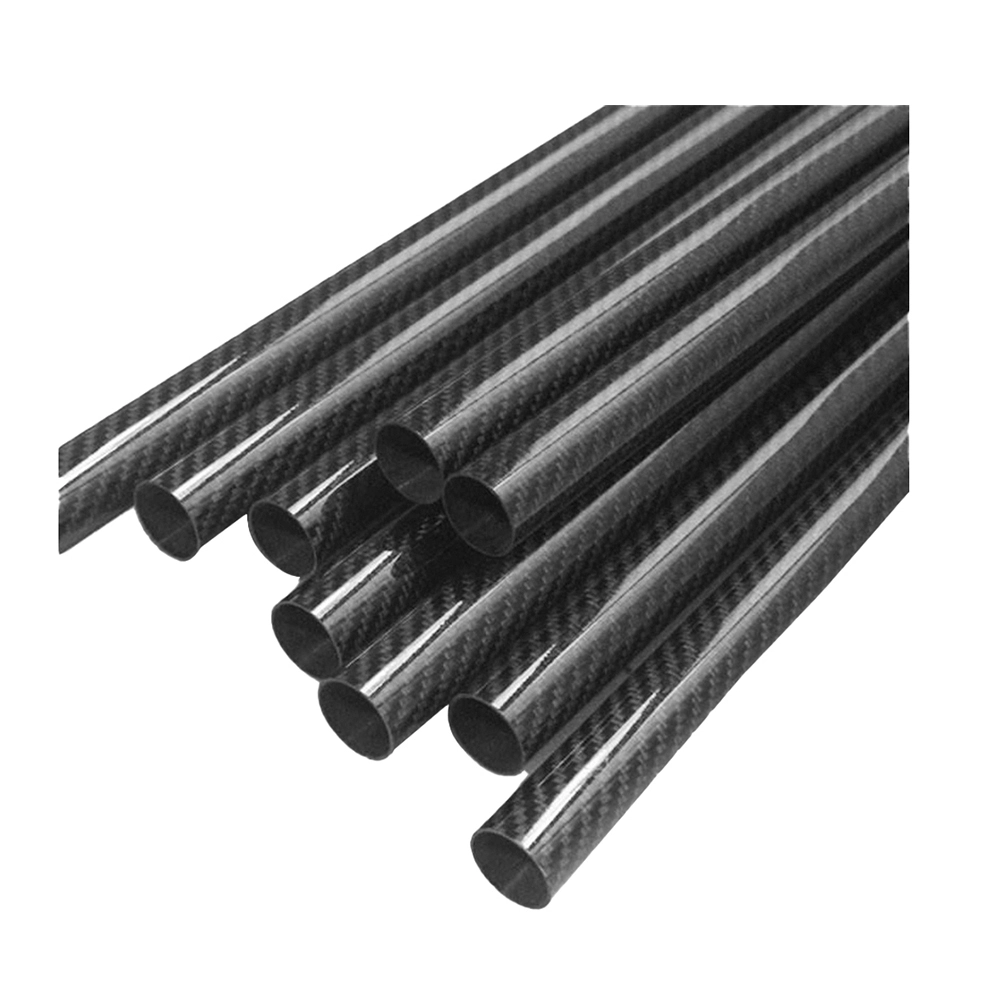

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

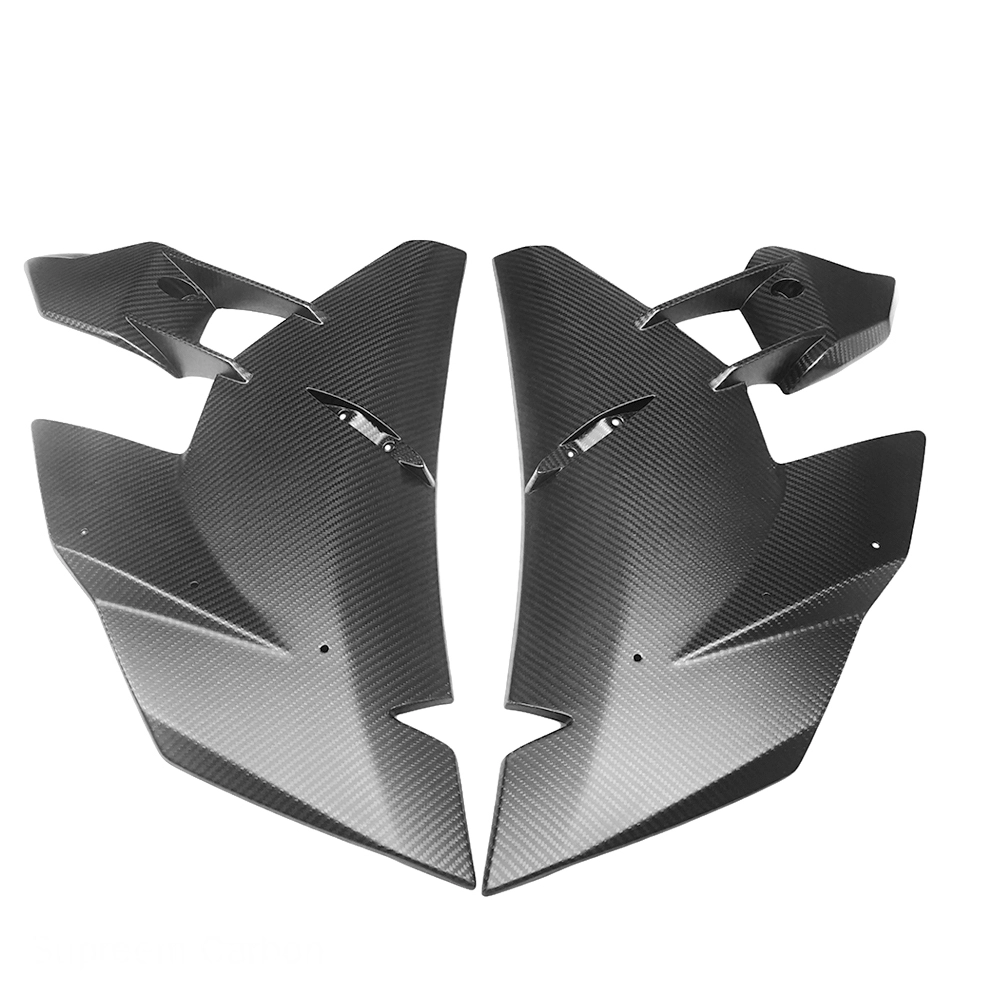

Kawasaki H2/H2R Carbon Fiber Side Fairing

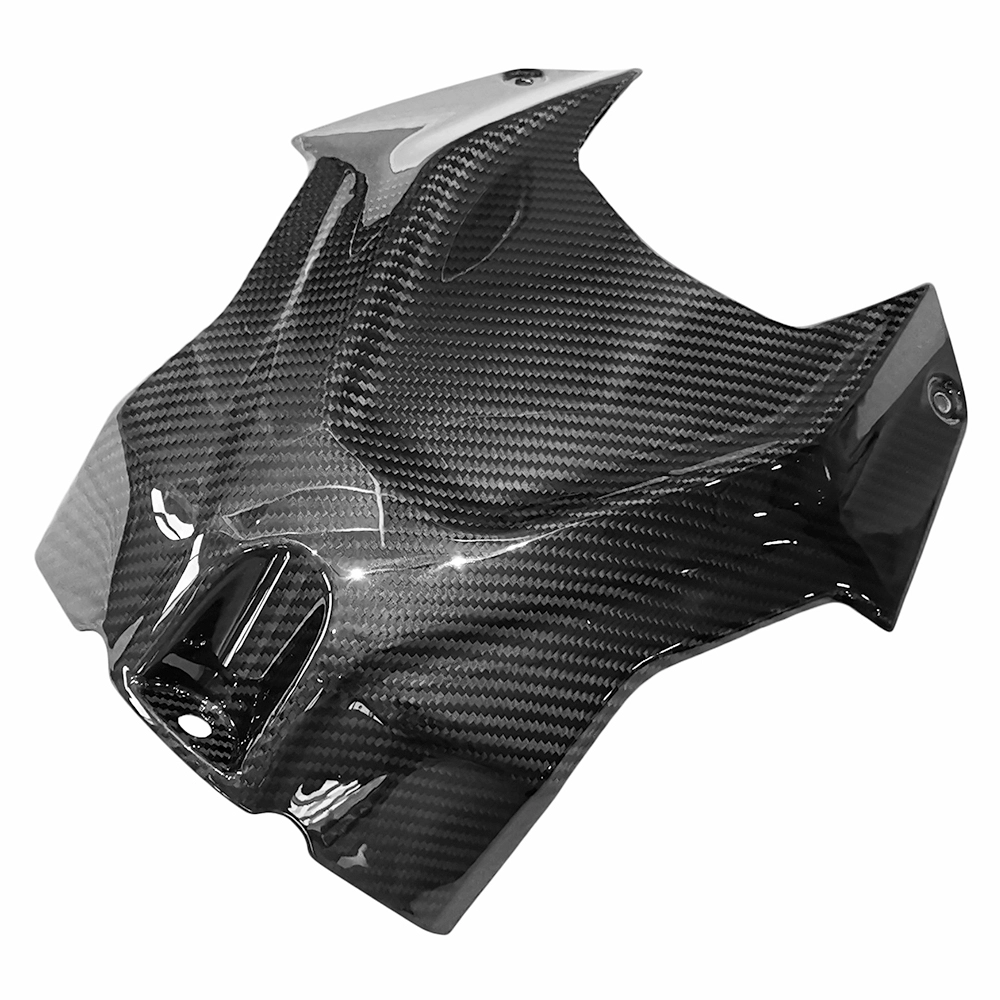

BMW S1000RR S1000R Carbon Fiber Tank Airbox Cover

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram