Supreem Carbon Fiber Tape – Durable & Lightweight Auto Solutions

Experience unparalleled strength and style with Supreem Carbon’s High Quality carbon fiber tape. Founded in 2017, Supreem Carbon is a trusted leader specializing in the research, design, and production of high-quality carbon fiber composite products tailored for automobiles and motorcycles. Our carbon fiber tape offers exceptional durability, lightweight performance, and a sleek aesthetic, making it the perfect choice for vehicle customization and repair.

Crafted with advanced technology in our 4,500-square-meter facility by 45 skilled professionals, Supreem Carbon’s tape ensures consistent quality and superior adhesion. Whether you are enhancing the look of your car or reinforcing components, our carbon fiber tape stands out for its resistance to wear, heat, and environmental factors, providing long-lasting protection and a modern finish.

As part of our extensive product range of over 1,000 items, including more than 500 customized carbon fiber parts, this tape embodies our dedication to innovation and excellence. Supreem Carbon not only meets but exceeds industry standards, allowing enthusiasts and professionals to elevate their projects with confidence.

Choose Supreem Carbon’s carbon fiber tape for a perfect balance of strength, flexibility, and style — the accessory for automotive and motorcycle customization. Discover more about our tailored solutions and superior craftsmanship at https://www.supreemcarbon.com/.

Advantages

Strong Production Capacity

We have a substantial daily production capacity to meet the demands of bulk orders, ensuring a smooth supply chain for you. Average monthly production capacity is nearly 3,500 pieces.

Rich R&D Experience

Our R&D team members are all professional and technical personnel who have been working in the carbon fiber industry for more than 10 years. We can understand customer needs as soon as possible and provide development technical support.

Professional Production Equipment

Our production facilities including Autoclaves, CNC machine, Heat-press machine to ensure efficient production and product consistency.

Professional development suggestions

Our engineers will provide customers with professional development suggestions based on different products and different uses.

Frequently Asked Questions

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

Aucra NSX Carbon Fiber Nose Beak Replacement

Honda CBR1000RR-R Carbon Fiber Front Fender

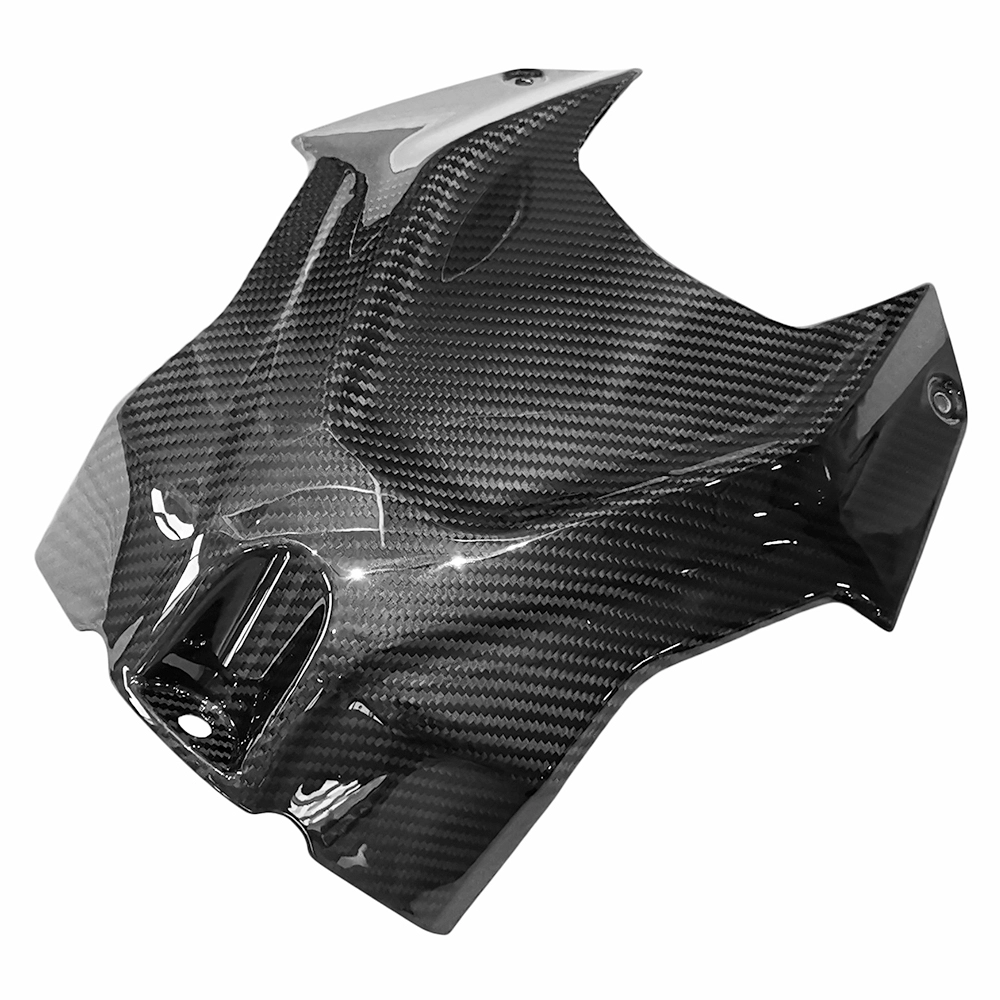

BMW S1000RR S1000R Carbon Fiber Tank Airbox Cover

Yamaha MT10 Carbon Fiber Exhaust cover

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram