Supreem Carbon: Leading Manufacturer of Carbon Fiber Solutions

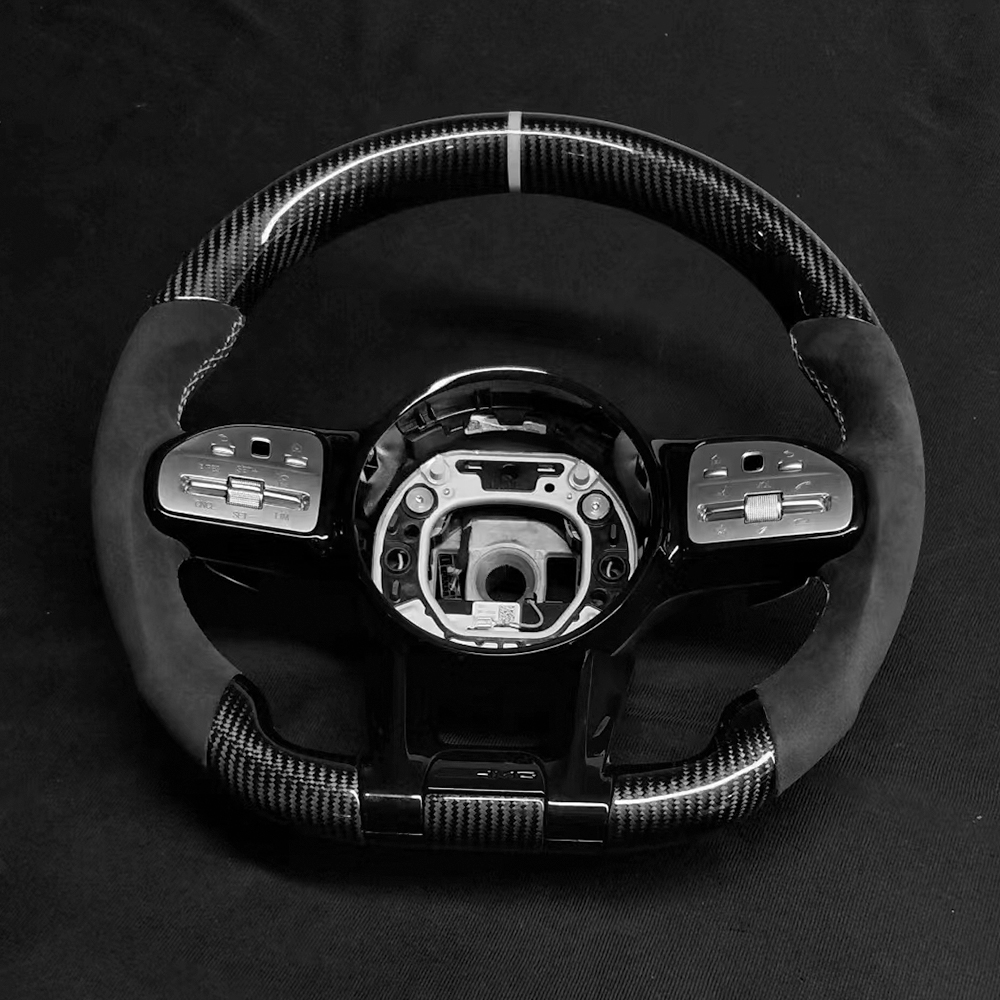

Product Description

Discover unparalleled excellence with Supreem Carbon, a leading Carbon Fiber Solutions Manufacturer. Established in 2017, Supreem Carbon is dedicated to transforming the future of automobiles and motorcycles by offering bespoke carbon fiber parts. Our commitment to innovation is reflected in every product, ensuring unmatched quality and performance.

Supreem Carbon seamlessly integrates R&D, design, production, and sales, delivering a comprehensive suite of services tailored to meet your specific needs. Our expertise lies in the research and development of advanced carbon fiber composite products, resulting in high-performance and visually striking automobile and motorcycle accessories.

Our expansive, state-of-the-art factory spans 4,500 square meters and is home to a highly skilled team of 45 production and technical staff members. This enables us to maintain a robust annual output valued at approximately 4 million dollars. With over 1,000 distinct products and 500 bespoke carbon fiber parts, Supreem Carbon empowers you to innovate and personalize your vehicles and lifestyle products.

Explore our diversified product line, which includes not only carbon fiber automobile and motorcycle accessories but also exquisite home luggage and cutting-edge sports equipment. Every product is meticulously crafted with the utmost precision, embodying our unwavering commitment to quality and customer satisfaction.

Trust Supreem Carbon to enhance your vehicles and lifestyle with our durable, high-performance carbon fiber solutions. Choose Supreem Carbon - where creativity meets craftsmanship.

Product Image

Our Advantages

After-sales support

The professional after-sales team can quickly solve some problems that customers have during product use and provide corresponding solutions.

Our products are meticulously crafted from premium carbon fiber material, renowned for its lightweight yet durable properties.

Strong Production Capacity

We have a substantial daily production capacity to meet the demands of bulk orders, ensuring a smooth supply chain for you. Average monthly production capacity is nearly 3,500 pieces.

Rich R&D Experience

Our R&D team members are all professional and technical personnel who have been working in the carbon fiber industry for more than 10 years. We can understand customer needs as soon as possible and provide development technical support.

Q&A

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

Are you parts have UV protected?

Absolutely! We use multiple layers of premium quality automotive clear (or matt) coats on our products, which ensure that they will remain super pretty for years to come.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

How many employees of Supreem carbon?

We have over 50 employees, including over 40 skilled workers, 3 R&D designers, and 5 QC professionals and so on.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

Ducati 848/1098/796/1198 Carbon Fiber Tail Cowl

Lamborghini Urus Carbon Fiber Engine Bay Panel

Enhance the visual appearance of your Urus engine bay with these custom carbon fiber engine covers. 100% handmade and a 1:1 copy of the original part, which retains all OEM screw mounting points. Elevate your driving experience with this exquisite addition, showcasing unparalleled craftsmanship and enhancing the allure of your Urus’s engine bay.

Ducati Monster 937 Carbon Fiber Engine Protect Cover

Ducati Panigale/Streetfighter V4 Carbon Fiber Heel Guards

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram