Tips for Wholesale carbon fiber parts

- Why Choose Carbon Fiber Parts?

- Tips for Sourcing Wholesale Carbon Fiber Parts

- Understanding Your Needs

- Partnering with Reputable Manufacturers

- Evaluating Cost-Effectiveness

- The Manufacturing Process of Carbon Fiber Parts

- Raw Material Selection

- Layering and Shaping

- Curing and Trimming

- Quality Assurance in Carbon Fiber Manufacturing

- Strategies for Successful Wholesale Purchases

- Bulk Buying Incentives

- Customized Solutions

- FAQs About Wholesale Carbon Fiber Parts

- What are the lead times for production?

- How do carbon fiber parts compare to metal parts?

- Can I see samples before placing a bulk order?

- What are the environmental impacts of using carbon fiber?

- Conclusion: Elevate Your Business with Supreem Carbon

Introduction to Wholesale Carbon Fiber Parts

In the ever-evolving world of manufacturing, carbon fiber parts have emerged as a game-changer across various industries. Known for their lightweight, high-strength, and corrosion-resistant properties, these parts are integral to today’s automotive, aerospace, and sports equipment industries. As a leader in this field, Supreem Carbon, established in 2017, specializes in creating top-tier custom carbon fiber automobile and motorcycle parts. Understanding the intricacies of wholesale procurement can significantly enhance your business's efficiency and profitability.

Why Choose Carbon Fiber Parts?

Carbon fiber parts are renowned for their durability and light weight. But what makes them the material of choice for engineers and designers worldwide? Their exceptional tensile strength means they perform under significant stress without breaking. This reliability makes them invaluable in high-performance areas such as motorsports and aerodynamics, where every gram counts. With over 1,000 types of products and more than 500 customized options, Supreem Carbon stands out as a trusted provider of these advanced materials.

Tips for Sourcing Wholesale Carbon Fiber Parts

Understanding Your Needs

Begin by assessing the specific requirements of your project. Are you looking for intricately designed parts for aesthetic purposes, or are performance-based components more critical? Supreem Carbon's expertise lies in integrating R&D, design, and production to ensure tailored solutions that meet diverse customer needs.

Partnering with Reputable Manufacturers

Partnering with a reliable manufacturer like Supreem Carbon is crucial. Our factory, covering 4,500 square meters with a dedicated technical team, ensures the consistency and quality of your carbon fiber parts. Investigate any potential partner’s production capabilities and their adherence to international quality standards.

Evaluating Cost-Effectiveness

Wholesale procurement should always strike a balance between cost and quality. While carbon fiber parts are generally more expensive than their metal counterparts, their longevity and performance often result in better return on investment. Supreem Carbon's annual output value of about 4 million dollars reflects our competitive pricing in this field.

The Manufacturing Process of Carbon Fiber Parts

Raw Material Selection

The journey begins with selecting high-grade carbon fiber precursors. Supreem Carbon's commitment to quality starts here, ensuring the resulting parts are robust and reliable.

Layering and Shaping

The next step involves layering, where multiple sheets of carbon fibers are laid out in specific orientations. This process is critical, as it defines the final strength and design flexibility of the part. Supreem Carbon uses advanced techniques to achieve the perfect balance for each component.

Curing and Trimming

After shaping, parts undergo a curing process, where resins harden under controlled temperatures. This step is essential for solidifying the structural integrity. Trimming follows, ensuring that each part fits precisely into its intended application.

Quality Assurance in Carbon Fiber Manufacturing

Quality assurance is a cornerstone of Supreem Carbon’s operations. Our rigorous testing procedures guarantee that every part aligns with the highest standards. Regular audits and continuous process improvements help maintain our reputation for excellence.

Strategies for Successful Wholesale Purchases

Bulk Buying Incentives

Bulk buying offers substantial cost benefits. At Supreem Carbon, we provide attractive discounts for large orders, encouraging businesses to scale efficiently while maintaining quality.

Customized Solutions

Customization can set your business apart from competitors. By working with our R&D and design teams, you can create unique carbon fiber parts tailored to specific market needs.

FAQs About Wholesale Carbon Fiber Parts

What are the lead times for production?

Lead times vary depending on the complexity and quantity of the order. Generally, Supreem Carbon ensures timely delivery by maintaining robust production schedules and efficient workflows.

How do carbon fiber parts compare to metal parts?

While more expensive initially, carbon fiber parts offer unmatched strength-to-weight ratios and corrosion resistance, often leading to longer life spans and better performance.

Can I see samples before placing a bulk order?

Yes, Supreem Carbon provides samples to help customers assess the quality and specifications of our products before committing to larger purchases.

What are the environmental impacts of using carbon fiber?

Carbon fiber parts are eco-friendly due to their durability and longevity, reducing the need for replacements and lowering waste. Supreem Carbon also adheres to sustainable practices in manufacturing.

Conclusion: Elevate Your Business with Supreem Carbon

The future of manufacturing lies in innovative materials like carbon fiber. By incorporating wholesale carbon fiber parts into your operations, you position your business at the forefront of industry advancements. Supreem Carbon, with its extensive expertise in customization and production, offers unparalleled services that ensure your growth and success. Our commitment to quality and innovation makes us the ideal partner as you explore the possibilities in carbon fiber technology.

Install Guide: Kawasaki ZX10R Carbon Fiber Belly Pan Fast Fit

Top Benefits of Custom Carbon Fiber Parts for Vehicles

3D Carbon Fiber Wrap: Transform Your Car | Supreem Carbon

Top carbon fiber bmw motorcycle parts Manufacturers and Suppliers

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

For Products

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

For After-sales Service

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

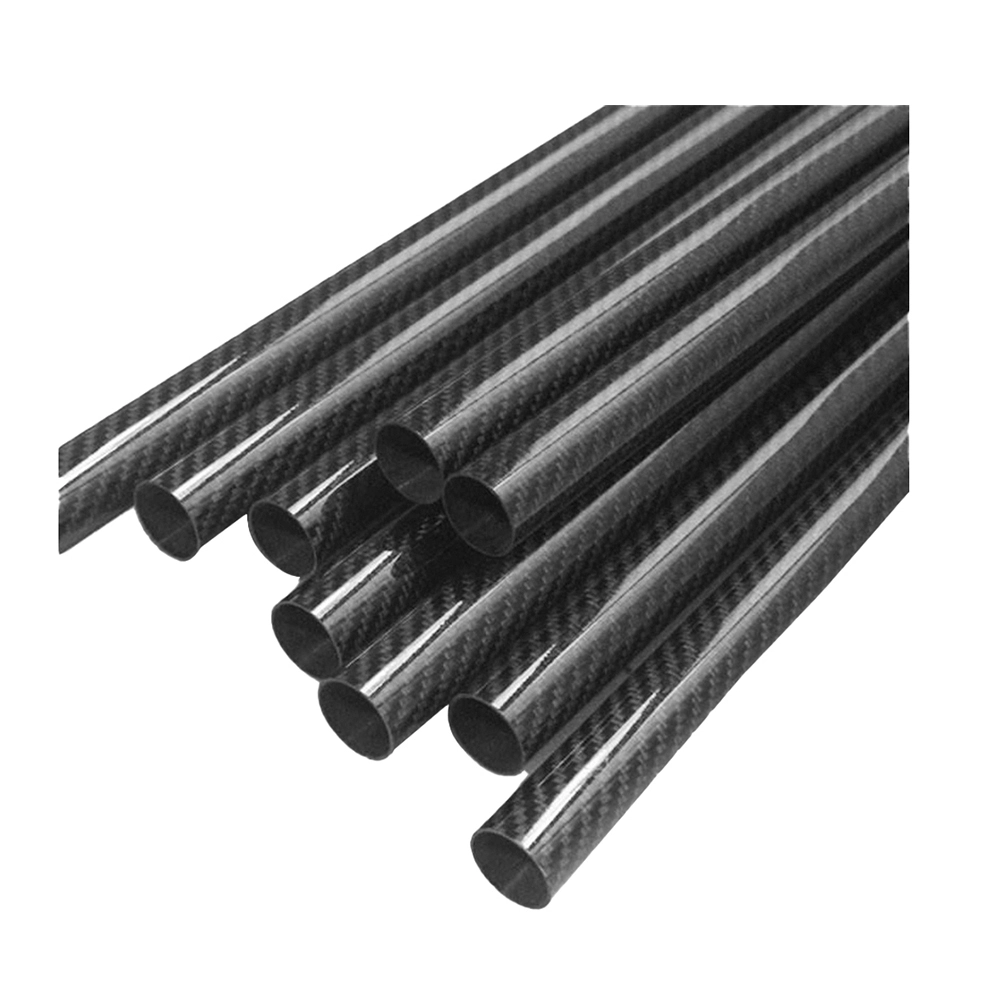

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Yamaha MT-07 Carbon Fiber Tank Cover

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram