Tips for Wholesale how to make carbon fiber car parts

- Elevate Your Business with Carbon Fiber Car Parts

- Understanding Carbon Fiber

- The Versatility and Demand for Carbon Fiber

- Setting Up a Manufacturing Process

- Integrating R&D into Production

- Designing High-Performance Parts

- Crafting Carbon Fiber Car Parts

- The Crafting Process: Start to Finish

- Ensuring Quality Control

- Scaling Up for Wholesale

- Efficient Production for Bulk Manufacturing

- Building Clientele and Distribution Channels

- FAQs

- Frequently Asked Questions about Making Carbon Fiber Car Parts

- Q1: What are the initial steps in learning how to make carbon fiber car parts?

- Q2: How can carbon fiber enhance automotive performance?

- Q3: What challenges might a business face in carbon manufacturing?

- Q4: How does Supreem Carbon ensure customization meets client specifications?

- Conclusion

- Partnering with Supreem Carbon for Wholesale Success

Introduction

Elevate Your Business with Carbon Fiber Car Parts

In the competitive landscape of the automotive industry, manufacturing carbon fiber car parts presents an exciting opportunity for businesses to elevate their offerings. As a leader in carbon fiber technologies, Supreem Carbon has been pioneering the customization and production of high-quality automobile and motorcycle accessories since its foundation in 2017. This article provides comprehensive insights into making carbon fiber car parts, offering valuable tips for wholesale manufacturers aiming at innovation and efficiency.

Understanding Carbon Fiber

The Versatility and Demand for Carbon Fiber

Carbon fiber is renowned for its strength-to-weight ratio, durability, and aesthetic appeal, making it a High-Quality choice in automotive design. Knowing how to make carbon fiber car parts not only broadens product portfolios but also meets escalating consumer demand for cutting-edge components. This fiber's unique properties make it ideal for varied applications, a niche that Supreem Carbon has successfully capitalized on by offering a vast array of over 1,000 proprietary products.

Setting Up a Manufacturing Process

Integrating R&D into Production

A successful carbon fiber production strategy begins with robust research and development. At Supreem Carbon, integrating R&D with production ensures that innovation translates seamlessly into high-quality products. To do this, businesses should invest in skilled personnel, state-of-the-art technology, and constant market analysis, which brings new product innovation and improves existing offerings.

Designing High-Performance Parts

Effective design is crucial in carbon fiber manufacturing. Utilizing advanced CAD software and simulation tools can help streamline the design process, cutting down on both time and trial-and-error in the production phase. This approach has empowered Supreem Carbon to maintain a leading edge in customization, addressing specific client needs effectively.

Crafting Carbon Fiber Car Parts

The Crafting Process: Start to Finish

The process of how to make carbon fiber car parts involves multiple meticulous steps. Begin with selecting high-quality carbon fiber fabric, followed by creating precise molds that shape the final product. Employ various layering techniques for maximum strength and finish, such as the wet lay-up or resin transfer method. Businesses should aim for precision and uniformity at every stage to ensure consistent quality and performance.

Ensuring Quality Control

In any manufacturing business, particularly with carbon fiber, maintaining rigorous quality control checks is indispensable. Testing for structural integrity, weight, and finish guarantees that products meet industry standards and customer expectations. Supreem Carbon thrives on adhering to stringent quality policies, resulting in trusted products across various markets.

Scaling Up for Wholesale

Efficient Production for Bulk Manufacturing

When scaling from small-scale manufacturing to wholesale, strategizing production processes is fundamental. Streamlining processes through machinery upgrades, employee training, and efficient supply chain management can significantly bolster output capacity. Supreem Carbon’s investment in a 4,500 square meters facility is an exemplar of scaling up to meet growing demands without compromising on quality.

Building Clientele and Distribution Channels

To succeed in wholesale markets, building strong relationships with dealerships and automotive retailers extends the reach of carbon fiber car parts. Furthermore, having a diversified marketing strategy that includes online marketplaces and international clients expands potential revenue streams.

FAQs

Frequently Asked Questions about Making Carbon Fiber Car Parts

Q1: What are the initial steps in learning how to make carbon fiber car parts?

A1: Begin by understanding the fundamental properties of carbon fiber, followed by acquiring materials and learning basic molding techniques.

Q2: How can carbon fiber enhance automotive performance?

A2: Carbon fiber’s lightweight and strength lower vehicle weight, improving speed and fuel efficiency.

Q3: What challenges might a business face in carbon manufacturing?

A3: Some challenges include high initial costs, the need for specialized equipment, and maintaining consistent quality.

Q4: How does Supreem Carbon ensure customization meets client specifications?

A4: Supreem Carbon relies on a team of expert designers and advanced technology to cater to specific client requests, consistently delivering precise products.

Conclusion

Partnering with Supreem Carbon for Wholesale Success

Supreem Carbon is committed to advancing the technology of carbon fiber car parts production, offering unparalleled expertise for businesses looking to capitalize on this burgeoning sector. Through comprehensive R&D, stringent quality control, and an unwavering focus on innovation, we stand as a reliable partner for those venturing into the realms of wholesale carbon fiber manufacturing.

Embrace the potential of carbon fiber, and let Supreem Carbon guide your business to new heights of performance and profitability.

Transform Your Project Car with Custom Carbon Fibre Parts - Supreem Carbon

Enhance Your Vehicle and Lifestyle with Custom Carbon Fiber Pieces from Supreem Carbon

Best professional carbon fiber rod manufacturers and supplier brands

Install Guide: Kawasaki ZX10R Carbon Fiber Belly Pan Fast Fit

For Facotry

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

For After-sales Service

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

For Products

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

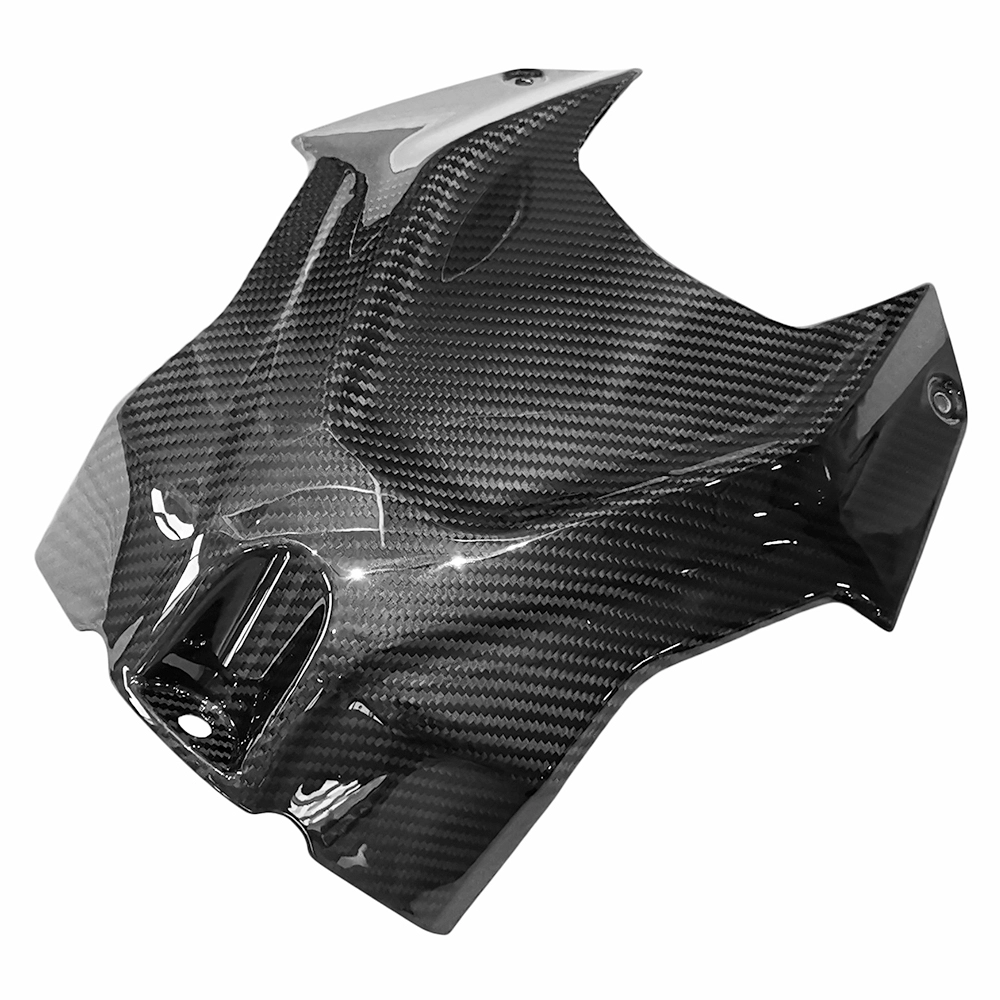

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

This carbon fiber rear seat panel is engineered for the BMW S1000R and M1000RR, offering superior rigidity, reduced weight, and a premium racing finish. Produced with autoclave technology and strict QC standards, the part ensures consistent OEM-level fitment. Supreem Carbon provides wholesale supply, stable bulk production, and customized solutions for global clients.

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Engineered for distributors, tuning brands, and motorcycle accessory businesses, the BMW S1000R Carbon Fiber Rear Undertail is a high-quality, durable, lightweight carbon fiber upgrade for the S1000R platform. This component is manufactured using aerospace-grade carbon fiber and precision molds to deliver superior stiffness, a seamless OEM-level fit, and a premium visual finish suitable for high-end aftermarket applications.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram