Wholesale Carbon Fiber BMW Hood

Supreem Carbon Fiber BMW Hood Wholesale – High Quality Customization for Your BMW

Upgrade your BMW with the finest quality carbon fiber BMW hood wholesale from Supreem Carbon. Established in 2017, Supreem Carbon is a leader in customized carbon fiber automobile and motorcycle parts, delivering precision-engineered products that combine style, strength, and performance.

Specializing in the research, development, and manufacturing of carbon fiber composite products, we offer an impressive range of over 1,000 carbon fiber items, with more than 500 customizable parts to meet individual needs. Our state-of-the-art factory covers 4,500 square meters and is staffed by a dedicated team of 45 highly skilled technicians, ensuring every product meets strict quality standards.

The carbon fiber BMW hood by Supreem Carbon is crafted from High Quality composite materials, offering a lightweight alternative to traditional hoods without sacrificing durability or fit. Designed for both personalization and enhanced performance, our hoods reduce vehicle weight, improve aerodynamics, and give your BMW a modern, sporty appearance.

For wholesale customers, Supreem Carbon provides competitive pricing, bulk order support, and flexible customization options. Our seamless process, from R&D to after-sales, ensures reliability, fast lead times, and products tailored exactly to your specifications. Whether you’re a retailer, automotive shop, or enthusiast club, you’ll benefit from our commitment to craftsmanship and customer satisfaction.

Choose Supreem Carbon for all your carbon fiber BMW hood needs — experience the value, innovation, and personalized service that set us apart in the industry.

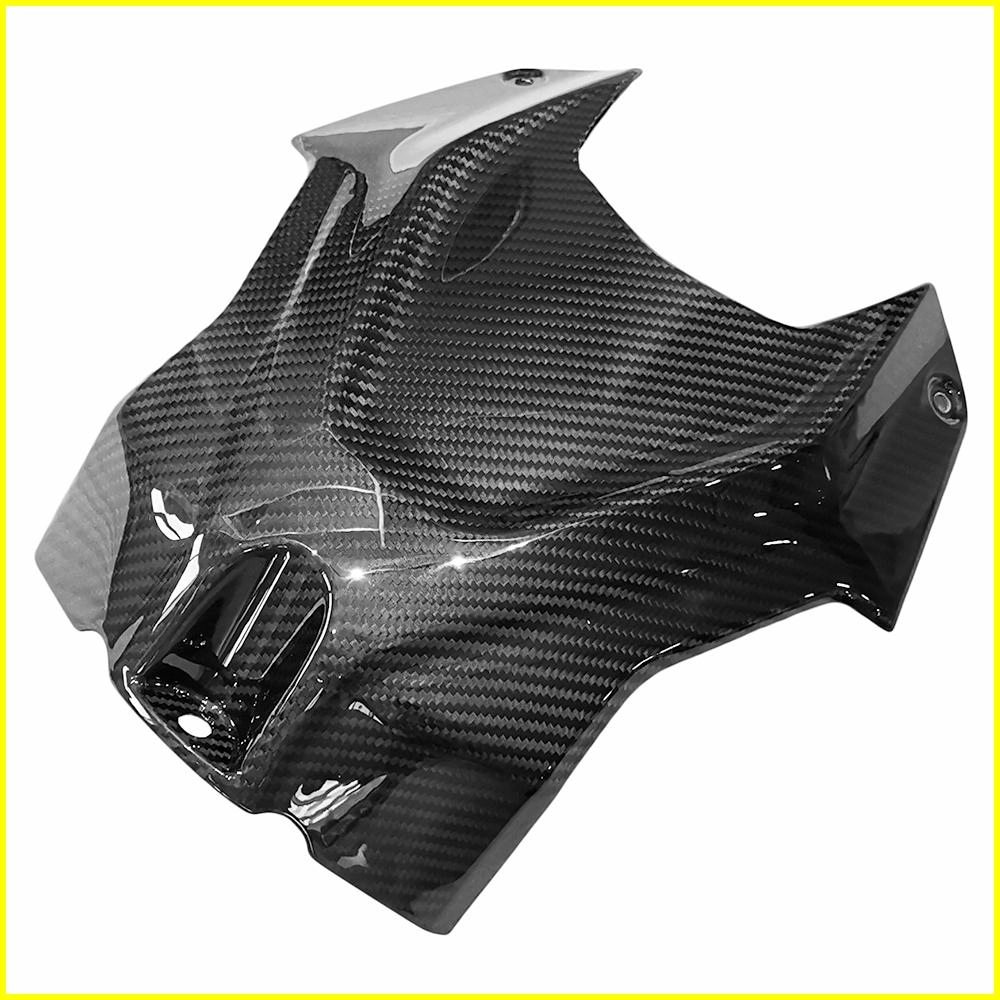

Product Image

Our Advantages

Weight

Engineered to be lightweight for effortless handling and portability without compromising on durability.

Project consultation

Our designers will provide customers with project feasibility analysis and quotations based on the ideas and design concepts or drawings provided by customers.

Professional development suggestions

Our engineers will provide customers with professional development suggestions based on different products and different uses.

Extensive Production Experience

Over 10 years of experience in carbon fiber products production, we are well-versed in various processes and production technologies to guarantee product quality stable and consistency.

FAQ

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

This carbon fiber rear seat panel is engineered for the BMW S1000R and M1000RR, offering superior rigidity, reduced weight, and a premium racing finish. Produced with autoclave technology and strict QC standards, the part ensures consistent OEM-level fitment. Supreem Carbon provides wholesale supply, stable bulk production, and customized solutions for global clients.

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Engineered for distributors, tuning brands, and motorcycle accessory businesses, the BMW S1000R Carbon Fiber Rear Undertail is a high-quality, durable, lightweight carbon fiber upgrade for the S1000R platform. This component is manufactured using aerospace-grade carbon fiber and precision molds to deliver superior stiffness, a seamless OEM-level fit, and a premium visual finish suitable for high-end aftermarket applications.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram