How hard is it to make carbon fiber car parts? | Supreem Carbon Guide

How Hard Is It to Make Carbon Fiber Car Parts?

Manufacturing high-performance carbon fiber car parts presents unique challenges. This article explores the complexities involved, from material selection to final finishing, providing insights for professionals in the carbon fiber industry. Understanding these difficulties is crucial for successful production and achieving desired quality in your carbon fiber components.

Material Selection and Preparation

The journey begins with selecting the right carbon fiber prepreg. The fiber type, resin system, and tow architecture significantly impact the final part's properties. Careful consideration must be given to the desired stiffness, strength, and weight requirements. Proper prepreg storage and handling are also critical to avoid degradation and ensure consistent quality in your carbon fiber parts. Improper handling can lead to reduced performance and manufacturing defects.

Layup and Curing

Precise layup is paramount. Each ply must be meticulously placed according to the design specifications. Variations in ply orientation or compaction can severely compromise the structural integrity and performance of the finished carbon fiber part. The curing process requires precise temperature and pressure control within a dedicated autoclave. Variations here can result in resin-rich or resin-starved areas, affecting both the mechanical properties and the surface finish of the carbon fiber component. Optimization of this process is key to successful manufacturing.

Machining and Finishing

Once cured, the carbon fiber part often requires machining to achieve precise dimensions and surface finishes. This process demands specialized tooling and expertise due to the material’s hardness and abrasive nature. Careful consideration must be given to avoid fiber damage during machining. Final finishing may involve sanding, polishing, and potentially painting or coating to achieve the desired aesthetic and protective qualities. This stage requires precision and patience.

Quality Control and Testing

Rigorous quality control measures throughout the entire process are essential. Non-destructive testing methods, such as ultrasonic inspection, are used to detect internal flaws. Destructive testing, such as tensile and flexural testing, is crucial for verifying the part’s mechanical properties meet design specifications. Consistent quality control ensures that each carbon fiber car part meets the stringent standards demanded by the automotive industry.

Application of 3D Printing in Carbon Fiber Accessories

Лучший производитель углеродного волокна в Китае

New arrivals---Carbon Fiber Slam Panel Replacement for BMW M3 M4

Chinese Carbon Fiber Manufacturer Brands: Supreem Carbon in the Spotlight

The Application of Carbon Fiber in Daily Household Products

100% Carbon fiber dash panel and window door trims set for NSX

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

For Order Delivery

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

For Customized Service

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

For Facotry

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

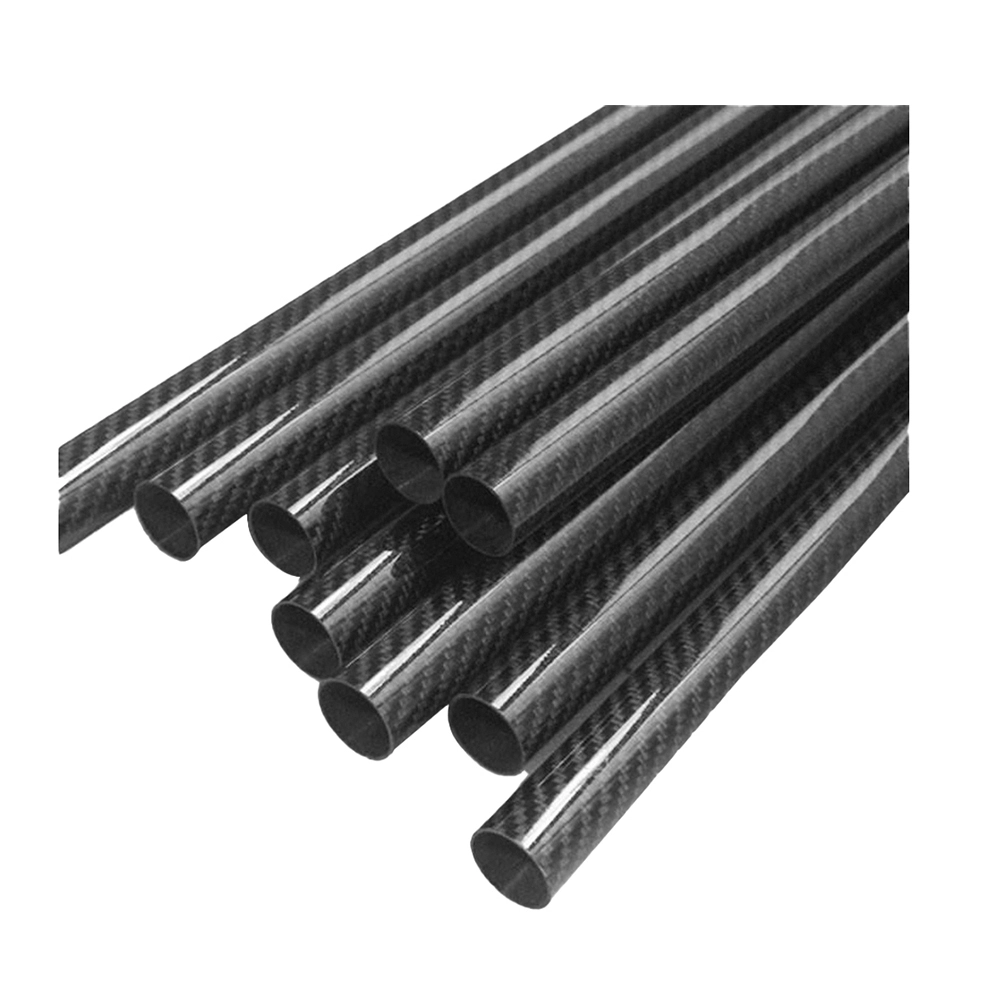

Carbon Fiber Sheet and Tube Custom

Ducati Panigale V4 Carbon Fiber Belly Pan Custom

Kawasaki Z650 Carbon Fiber Tank Side Panels

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram