How to Make Carbon Fiber Car Parts?

Learn how carbon fiber transforms from raw material into advanced automotive components. This guide walks through each production stage.

- 1. What Exactly Is Carbon Fiber?

- Why it’s perfect for automotive parts:

- Common Types of Carbon Fiber

- 2. How Carbon Fiber Car Parts Are Manufactured

- 2.1 The Design Phase – Where Everything Begins

- 2.2 Material Preparation – Choosing the Right Carbon Fiber

- 2.3 Forming Techniques – Shaping the Carbon Fiber

- Hand Layup Method

- Molding

- Vacuum Bagging

- 3. Curing and Post-Processing

- Curing Options

- Post-Processing Includes:

- 4. Quality Control: Ensuring Strength & Reliability

- 5. Real Applications of Carbon Fiber in Automotive Manufacturing

- Exterior Components

- Interior Components

- Structural Parts

- 6. The Future of Carbon Fiber in the Automotive World

- Conclusion: Why Partner with Supreem Carbon?

Have you ever wondered how carbon fiber car parts are made? Over the past decade, carbon fiber materials have become one of the most sought-after solutions in the automotive industry—and for good reason. They are incredibly lightweight and strong, resistant to corrosion, and provide an aesthetic that instantly elevates any vehicle.

Carbon fiber is now widely used in supercars, race cars, premium motorcycles, electric vehicles (EVs), and aftermarket performance upgrades. In this article, we will walk through the entire carbon fiber manufacturing process, explore how automotive components are produced, and learn why Supreem Carbon has become a trusted leader in delivering custom carbon fiber parts to clients around the world.

1. What Exactly Is Carbon Fiber?

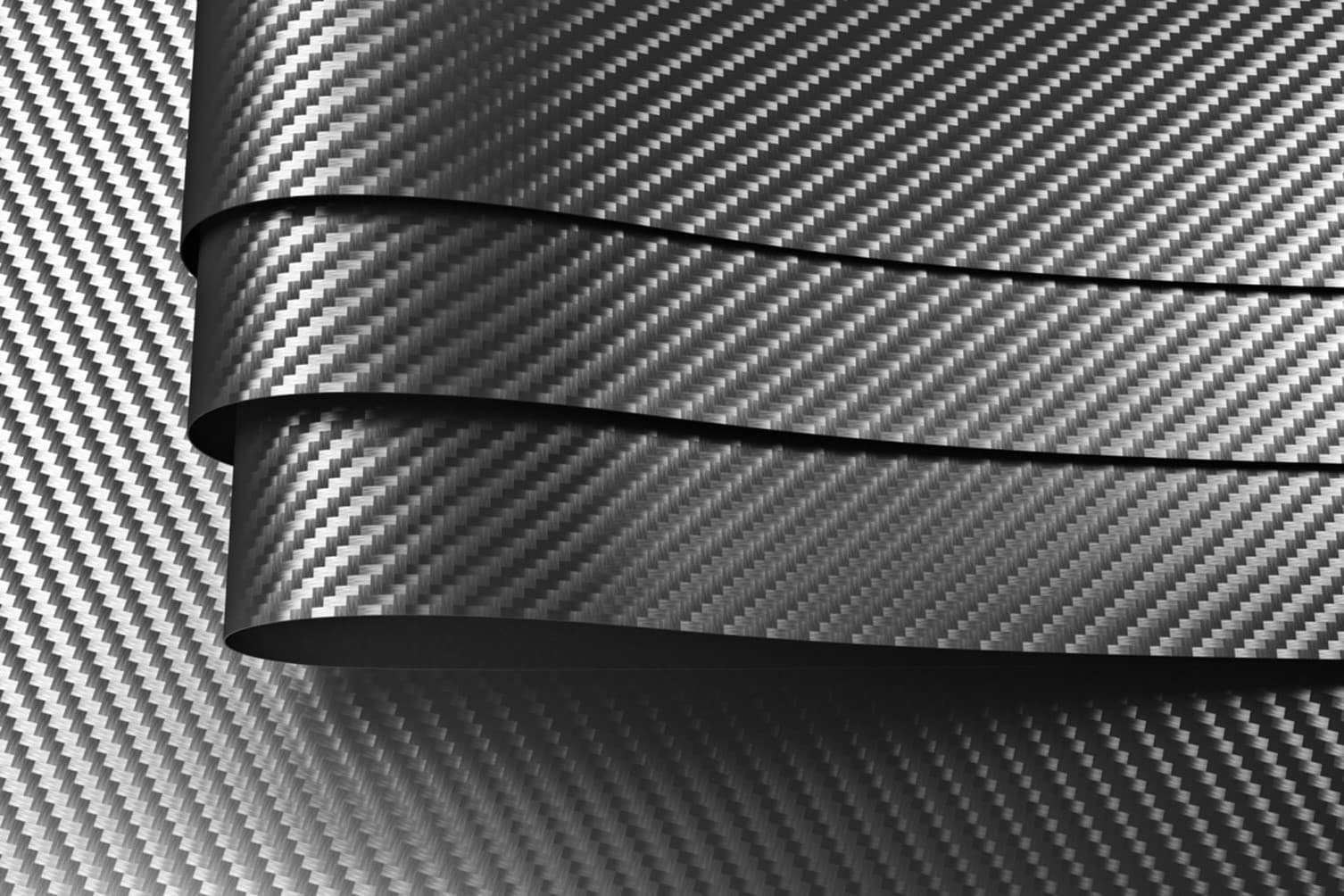

Carbon fiber is a high-strength composite material consisting of extremely thin strands of carbon atoms. These strands are tightly bonded in a crystalline alignment, which gives carbon fiber its renowned combination of light weight and exceptional strength.

Why it’s perfect for automotive parts:

- 5X stronger than steel but much lighter

- Resistant to corrosion and rust

- High thermal and chemical resistance

- Premium layered carbon weave aesthetic

- Excellent stiffness for performance engineering

Automotive manufacturers typically use different grades of carbon fiber depending on the application:

Common Types of Carbon Fiber

- Twill Weave – popular for exterior parts and performance styling

- Plain Weave – great for structural strength

- UD (Unidirectional) – used for high-strength load-bearing components

- Prepreg Carbon – premium-grade, pre-impregnated with resin for maximum quality

Understanding these material differences helps you select the right option based on performance needs, appearance, and budget.

2. How Carbon Fiber Car Parts Are Manufactured

Creating high-quality carbon fiber components is a precise and highly controlled process. Below, we break down the main stages used by professional manufacturers like Supreem Carbon.

2.1 The Design Phase – Where Everything Begins

Before any production starts, the part must be engineered using CAD modeling.

This step determines:

- Shape and fitment

- Strength requirements

- Weight optimization

- Layer orientation

- Tooling and mold design

Supreem Carbon’s engineering team uses advanced computer-aided design (CAD) and simulation tools to ensure that each custom carbon fiber part meets performance and durability requirements. Additionally, they evaluate surface aesthetics and weave alignment to deliver a flawless final appearance.

2.2 Material Preparation – Choosing the Right Carbon Fiber

The material used directly impacts the performance of the final part. Manufacturers typically select from:

- Fiber sheets pre-coated with resin

- Highest quality option

- Used for performance and motorsport parts

Dry Carbon Cloth

- Requires manual resin application

- More economical

- Ideal for large body parts

Resin Types

- Epoxy Resin: superior strength and heat resistance

- Polyester Resin: cost-effective for non-structural components

Supreem Carbon provides material selection consulting for B2B clients, ensuring each project uses the optimal combination of fiber grade, weave type, and resin system.

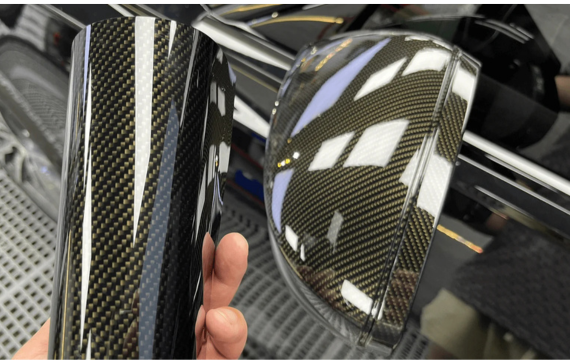

2.3 Forming Techniques – Shaping the Carbon Fiber

Hand Layup Method

A traditional but highly effective method where technicians manually:

- Cut the fabric

- Lay each layer on the mold

- Align the weave

- Apply resin (if not prepreg)

- Compact the layers

Used for body panels, interior trims, fairings, and aesthetic parts.

Molding

Precision molds ensure the final product matches exact OEM dimensions. Supreem Carbon develops molds from:

- CNC-machined aluminum

- Steel

- High-temperature composite tooling

This guarantees dimensional stability, perfect fitment, and consistent quality.

Vacuum Bagging

Once layers are applied, the material is enclosed in a vacuum bag and pressure is applied to:

- Remove trapped air

- Compact layers evenly

- Improve structural integrity

- Enhance resin flow

Vacuum bagging is considered an essential step for achieving a strong and smooth carbon fiber part.

3. Curing and Post-Processing

After forming, the part is moved into a curing oven or autoclave. This stage hardens the resin and bonds all layers into a rigid composite.

Curing Options

- Room-temperature curing: for non-structural parts

- Oven curing: stronger and more stable

- Autoclave curing: maximum performance (used in aerospace & motorsports)

Post-Processing Includes:

- Trimming excess edges

- Precision machining

- Surface finishing

- UV-protection clear coating

- Polishing for cosmetic-grade parts

Supreem Carbon’s finishing process ensures that every part achieves a flawless high-gloss or matte surface, depending on customer requirements.

4. Quality Control: Ensuring Strength & Reliability

We understand the importance of quality control. That's why we ensure our carbon fiber car parts meet industry standards. At Supreem Carbon, we dedicate ourselves to ensuring that each product we manufacture meets the highest standards. We use ultrasonic testing and X-ray inspection to ensure our components are top-notch.

5. Real Applications of Carbon Fiber in Automotive Manufacturing

Carbon fiber is used in an ever-growing range of vehicle components:

Exterior Components

- Hoods

- Fenders

- Front lips

- Spoilers

- Side skirts

- Rear diffusers

Interior Components

- Dashboard trims

- Door handles

- Center console covers

Structural Parts

- Chassis reinforcements

- Seat frames

- Crash structures (for racing)

- Carbon fiber improves:

- Performance

- Acceleration

- Fuel efficiency

- Heat resistance

- Aesthetics and resale value

6. The Future of Carbon Fiber in the Automotive World

Innovation is moving fast. With improved automated processes, lower raw material costs, and rising EV adoption, carbon fiber parts will continue expanding into mainstream automotive production.

Upcoming trends include:

- Carbon fiber battery housings

- Structural EV components

- Lightweight aerodynamic kits

- Hybrid composite-metal designs

- Recycled carbon fiber applications

Supreem Carbon continues investing in new technologies to stay at the forefront of this rapidly evolving industry.

Conclusion: Why Partner with Supreem Carbon?

Carbon fiber has evolved from a material used exclusively for race cars to a cornerstone of modern automotive engineering. Its unmatched strength-to-weight ratio, durability, and aesthetic appeal make it one of the most valuable materials for automotive customization and original equipment manufacturing (OEM).

Supreem Carbon has nearly a decade of experience providing:

- Custom carbon fiber parts

- OEM/ODM manufacturing

- Advanced composite engineering

- High-quality finishing and QC

- Global B2B supply and logistics

Whether you’re a tuning brand, automotive manufacturer, motorsports team, or aftermarket distributor, Supreem Carbon offers the expertise and production capability to bring your carbon fiber projects to life.

If you’re ready to enhance performance, reduce weight, and upgrade your vehicle with premium composite materials, Supreem Carbon is your trusted partner for custom carbon fiber parts.

Carbon Fiber Helmet produced by Supreem Carbon.

The Advantages of Carbon Fiber Materials—Insights from Industry Experts

Asia's Top Carbon Fiber Motorcycle Accessory Brand

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

Ducati DesertX 2022 new arrivals!

Best 10 Carbon Fiber Parts Manufacturers in 2026: Industry Leaders Ranked

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

For Facotry

When is Supreem carbon founded?

Our company formally established in early 2017.

For Products

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

For Order Delivery

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

Chevrolet Corvette C8 Carbon Fiber Bumper Trim Customization

This carbon fiber front grill trim fits C8 OEM parts. Our products are not only lighter than ABS, but they are also corrosion-resistant and have a UV-protective coating. 100% handmade, dry-carbon autoclave process. It can directly replace original vehicle parts.

Custom Carbon Fiber Wine Bracket

A carbon fiber wine bracket is a premium display solution engineered to combine modern aesthetics with exceptional structural performance. Manufactured from high-strength carbon fiber composite materials, it offers a lightweight yet rigid support system for securely holding and showcasing wine bottles. Its refined texture, durability, and contemporary design make it ideal for luxury retail environments, custom interior projects, and high-end hospitality applications.

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Engineered for distributors, tuning brands, and motorcycle accessory businesses, the BMW S1000R Carbon Fiber Rear Undertail is a high-quality, durable, lightweight carbon fiber upgrade for the S1000R platform. This component is manufactured using aerospace-grade carbon fiber and precision molds to deliver superior stiffness, a seamless OEM-level fit, and a premium visual finish suitable for high-end aftermarket applications.

Honda NSX Carbon Fiber Interior Door Handles Replacement

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram