Application Advantages of Carbon Fiber in Automobile Chassis Brackets

In the automotive industry, the continuous pursuit of higher performance, increased safety, and weight reduction has led to the widespread adoption of advanced materials such as carbon fiber. Among its many applications, carbon fiber has become a key component in the design and manufacture of automobile chassis brackets. These components, crucial for supporting various mechanical parts of a vehicle, benefit significantly from the unique properties of carbon fiber. Below, we explore the key advantages of using carbon fiber in automobile chassis brackets and how this material contributes to the overall improvement of automotive performance and safety.

1. Lightweight Construction

One of the most significant advantages of carbon fiber in automotive applications is its exceptional lightweight nature. Compared to traditional materials such as steel or aluminum, carbon fiber is much lighter while offering comparable or even superior strength. This reduction in weight plays a crucial role in improving the performance of a vehicle. Lighter chassis brackets help reduce the overall weight of the car, which directly impacts the car’s acceleration, fuel efficiency, and handling.

By reducing the weight of the vehicle’s chassis, manufacturers can achieve a better power-to-weight ratio, which is particularly important in sports cars, luxury vehicles, and performance-driven models. The lighter the car, the less effort is required to propel it forward, resulting in improved acceleration and enhanced overall driving dynamics. Additionally, reduced vehicle weight can also contribute to improved fuel efficiency and lower CO2 emissions, which are increasingly important in today’s environmentally-conscious market.

2. Enhanced Strength and Rigidity

Despite its lightweight nature, carbon fiber is known for its remarkable strength-to-weight ratio. In the case of automobile chassis brackets, carbon fiber offers superior tensile strength, ensuring that the brackets can withstand high-stress loads and forces during driving without deforming or failing. The rigid structure of carbon fiber components enhances the overall stability and performance of the vehicle, especially in high-performance driving situations.

The strength and rigidity provided by carbon fiber help maintain the structural integrity of the chassis, which is critical in ensuring that the vehicle remains safe and stable even in extreme conditions. This is particularly advantageous in motorsports and high-performance vehicles, where chassis brackets must endure significant forces without compromising the vehicle’s control or safety.

3. Corrosion Resistance

A significant issue with metal chassis brackets, particularly those made of steel, is susceptibility to corrosion. Metals can rust over time when exposed to moisture, road salts, and other environmental factors. This can lead to the deterioration of the components, reducing their strength and, ultimately, the safety of the vehicle.

Carbon fiber, on the other hand, is naturally resistant to corrosion. It does not rust, and it is highly resistant to degradation from environmental factors such as moisture, UV rays, or chemicals. This makes carbon fiber chassis brackets a durable and long-lasting solution, reducing the need for frequent maintenance or replacement. The corrosion resistance of carbon fiber is especially beneficial in regions where vehicles are subjected to harsh weather conditions or salty environments, such as coastal areas or locations with heavy winter road salting.

4. Improved Vehicle Handling and Safety

The use of carbon fiber in chassis brackets also contributes to improved handling and safety. Carbon fiber’s high strength, combined with its light weight, results in a more balanced and stable chassis. This contributes to better vehicle handling, as the car responds more efficiently to steering inputs and suspension adjustments. Lighter chassis components can also reduce the overall body roll of the car, allowing for more precise control and a smoother driving experience.

In terms of safety, the rigidity of carbon fiber allows for greater impact resistance. In the event of a collision, the strength of carbon fiber components helps distribute impact forces more evenly throughout the structure of the vehicle, reducing the likelihood of significant damage to the chassis. This enhanced safety feature is crucial in performance vehicles where high-speed driving can increase the risk of accidents.

5. Customization and Design Flexibility

Another advantage of using carbon fiber in chassis brackets is the material's design flexibility. Carbon fiber can be molded into complex shapes, allowing for custom-designed chassis brackets that meet specific performance requirements. Manufacturers can create lightweight, optimized components tailored to the unique needs of each vehicle model, whether it’s for enhancing aerodynamics, improving handling, or optimizing crash protection.

Additionally, the ability to mold carbon fiber into different shapes and sizes gives manufacturers the opportunity to reduce the overall number of components required in the chassis, leading to a more streamlined and efficient manufacturing process. This reduction in part complexity can also result in cost savings, especially in high-volume production.

6. Aesthetic Appeal

While functional benefits are at the forefront of using carbon fiber in chassis brackets, the material’s aesthetic qualities cannot be ignored. Carbon fiber is often associated with high-performance and luxury vehicles, and its distinctive woven pattern adds a touch of modernity and exclusivity to the car's design. Many automobile manufacturers choose to showcase their carbon fiber components, as the sleek, polished look of carbon fiber helps convey a sense of cutting-edge technology and craftsmanship.

For customers who prioritize both performance and aesthetics, carbon fiber chassis brackets provide a compelling solution that combines function with style. The lightweight yet visually striking material is a hallmark of luxury sports cars and high-performance vehicles.

Conclusion

The use of carbon fiber in automobile chassis brackets offers significant advantages, from reducing vehicle weight to enhancing strength, durability, and safety. These benefits make carbon fiber an ideal material for high-performance and luxury vehicles, where every detail counts in achieving optimal performance, safety, and aesthetics. With its lightweight properties, impressive strength-to-weight ratio, corrosion resistance, and customization potential, carbon fiber is transforming the automotive industry and driving innovation in vehicle design and manufacturing. As automotive technology continues to evolve, carbon fiber will undoubtedly play an increasingly pivotal role in the development of the next generation of vehicles.

Supreem Carbon: Asya'nın En İyi Profesyonel Motosiklet Karbon Fiber Üretici Markası

Best 10 Carbon Fiber Parts Manufacturers in 2026: Industry Leaders Ranked

Understanding the Difference Between Dry Carbon and Wet Carbon Products

2023 BMW S1000RR Carbon Fiber Body Kit released by Supreem Carbon

Great News!!! Ducati V4 SP new arrivals released.

What does carbon fiber do for a motorcycle?

For Facotry

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

Porsche GT3RS Carbon Fiber Full Sets Aerodynamics Kits

Chevrolet Corvette C8 Carbon Fiber Bumper Trim Customization

This carbon fiber front grill trim fits C8 OEM parts. Our products are not only lighter than ABS, but they are also corrosion-resistant and have a UV-protective coating. 100% handmade, dry-carbon autoclave process. It can directly replace original vehicle parts.

Volkswagen Golf R Mk8 Carbon Fiber Front Bumper Surrounds

We are committed to providing customers with the highest quality aerodynamic kits, just like this Volkswagen front bumper surround, which gives you a different visual experience. Not only are our products lighter than ABS, but they are also corrosion-resistant and have a UV-protective coating. 100% handmade, dry carbon autoclave process. It can directly replace original vehicle parts.

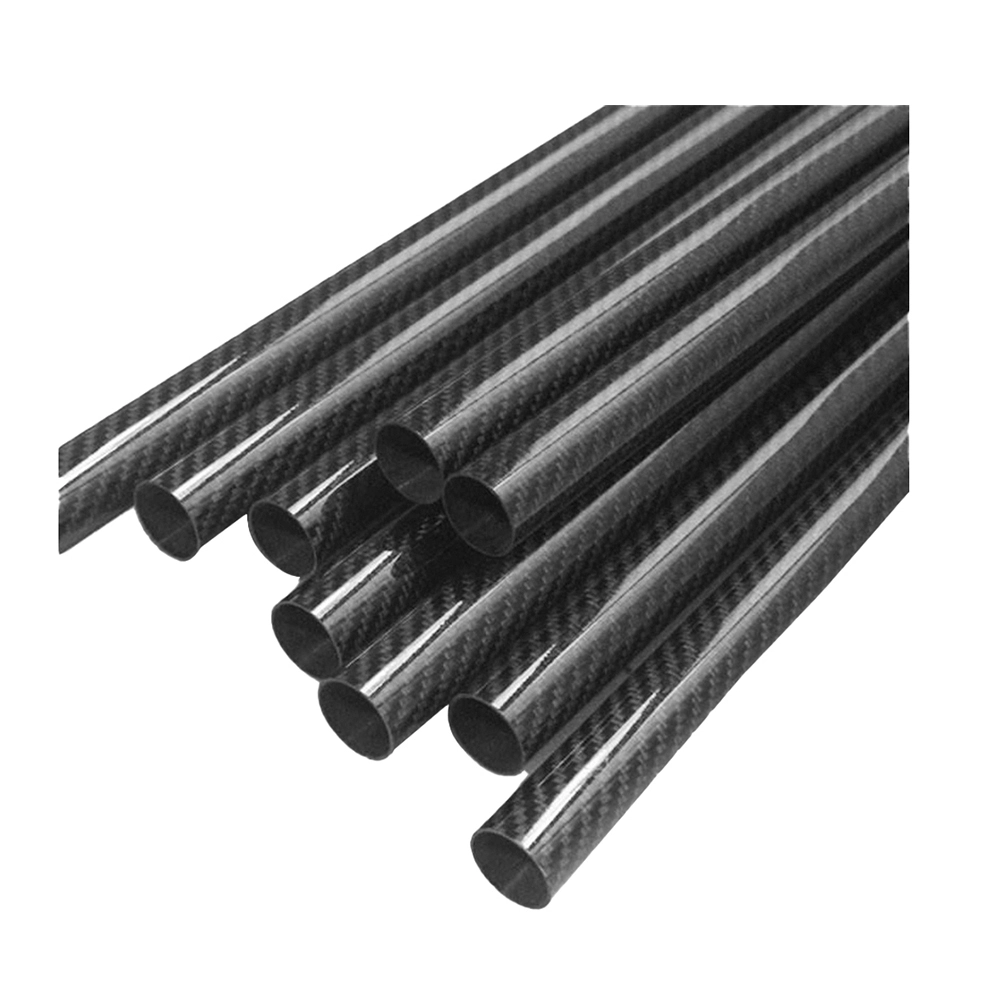

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram