Analysis of Delamination Problems in Carbon Fiber Products and How to Avoid it

Discover insights into delamination in carbon fiber products. Our analysis explores common causes of carbon fiber delamination and effective strategies to prevent it, ensuring the longevity and reliability of your products. Enhance your understanding of delamination challenges and solutions by reading our comprehensive guide tailored for industry professionals.

Delamination is a common issue in carbon fiber products where layers of the composite material separate or fail to bond correctly. This issue compromises the structural integrity, performance, and durability of the product. Understanding the causes of delamination and adopting preventive measures is critical for maintaining product quality in industries such as aerospace, automotive, and sporting goods.

Causes of Delamination in Carbon Fiber Products

1. Manufacturing Defects

Improper Resin Infusion or Distribution: Uneven resin flow during processes like resin infusion can create voids or weak bonds between layers.

Contamination: Dust, oils, or other impurities on the fiber layers or mold can prevent proper bonding.

Insufficient Pressure: Inadequate pressure during the curing process leads to weak interlayer adhesion.

Improper Curing: Incorrect temperature or timing during curing can prevent the resin from fully bonding the fibers.

2. Material Incompatibility

Using incompatible resins and fibers or mixing materials with differing thermal expansion properties can cause internal stress, leading to delamination.

3. Mechanical Stress

Excessive impact, vibration, or fatigue from usage can cause layers to separate over time.

4. Environmental Factors

Moisture Ingress: Prolonged exposure to moisture can weaken the bond between layers.

Thermal Cycling: Repeated heating and cooling can cause expansion and contraction, stressing the layers.

5. Design and Fabrication Issues

l Sharp corners, abrupt thickness transitions, or improper fiber orientation can create stress concentration points that lead to delamination.

Preventing Delamination in Carbon Fiber Products

Optimized Manufacturing Processes

Surface Preparation: Clean and prepare all materials and molds thoroughly to remove contaminants.

Uniform Resin Application: Ensure even resin distribution using controlled infusion or automated processes.

Proper Pressure Application: Use autoclaves or vacuum bags to apply consistent pressure, ensuring layers bond without voids.

Curing Control: Strictly monitor temperature and time during curing to ensure complete bonding.

Material Selection

Choose high-quality, compatible resins and fibers to ensure strong interfacial bonding.

Use pre-preg (pre-impregnated fiber) materials, which are pre-coated with resin and offer more consistent bonding.

Design Optimization

Avoid sharp corners or abrupt transitions in thickness to minimize stress concentration.

Orient fibers strategically to handle anticipated loads and stress directions.

Post-Manufacturing Quality Control

Inspect finished products using non-destructive testing (NDT) methods like ultrasonic testing, X-ray, or thermography to detect voids or weak spots.

Conduct pull tests or interlaminar shear tests on samples to verify layer adhesion strength.

Environmental Protection

Apply protective coatings to shield products from moisture and UV exposure.

Design for thermal stability, considering the operational environment of the product.

Training and Best Practices

Train operators in best practices for handling and fabricating carbon fiber materials.

Regularly calibrate and maintain equipment used in the manufacturing process.

Addressing Delamination During Use

For existing products, addressing delamination depends on the severity of the issue:

Minor Delamination: Apply repair techniques like resin injection or adhesive bonding, followed by re-pressurization or curing.

Severe Delamination: Replace the affected part entirely, as structural integrity may already be compromised.

Delamination is a critical concern in carbon fiber products that can significantly reduce performance and reliability. By identifying its root causes, optimizing manufacturing techniques, selecting appropriate materials, and implementing rigorous quality controls, manufacturers can minimize the risk of delamination. Proactively addressing these challenges ensures the long-term success of carbon fiber products in high-performance applications.

How Long Does Carbon Fiber Last? Unveiling the Durability of a Tech Marvel

Carbon Fibers: What Are They and Why Are They Everywhere? (Production, Properties, and Uses Explained)

Supreem carbon Auto part new arrivals!

Le fabricant leader de fibre de carbone personnalisée en Europe

Supreem Carbon: Asya'nın En İyi Profesyonel Motosiklet Karbon Fiber Üretici Markası

Supreem Carbon new engine cover released!

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

For Products

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

For After-sales Service

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

For Order Delivery

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

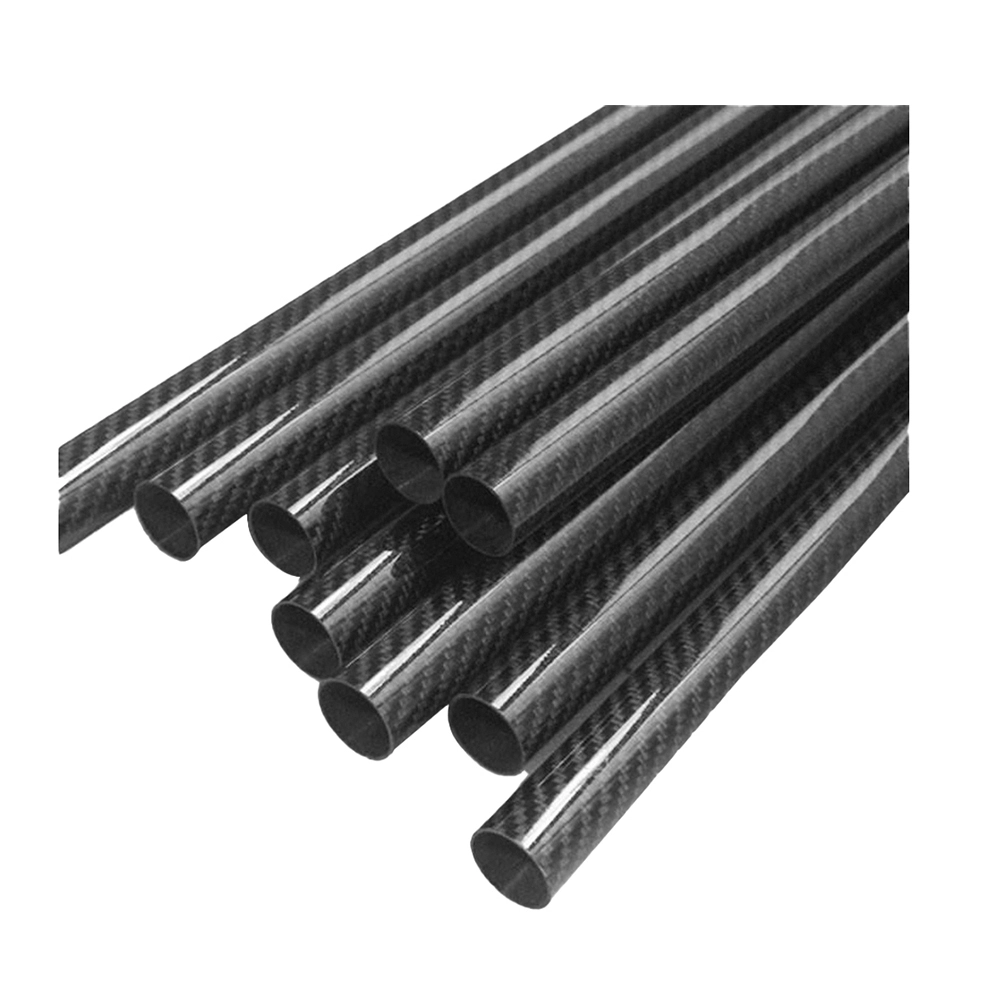

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Yamaha MT-07 Carbon Fiber Tank Cover

Honda CBR1000RR-R Carbon Fiber Tank Side Panels

Honda CBR1000RR-R Carbon Fiber Belly Pan Lower Side Fairings

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram