The Advantages of Carbon Fiber Materials—Insights from Industry Experts

Carbon fiber materials are transforming the way industries design and manufacture products. Renowned for their impressive strength-to-weight ratio and corrosion resistance, these advanced composites have become indispensable in the aerospace, automotive and sports industries. Engineers and manufacturers are increasingly relying on carbon fiber for its unmatched performance and sustainability benefits.

In this article, we will explore the major advantages of carbon fiber materials, how they outperform traditional metals, and why they represent the future of engineering innovation.

In today's high-performance industries, the demand for materials that are both lightweight and durable continues to rise. Carbon fibre material has become synonymous with strength, innovation, and precision engineering and is used in everything from aerospace components to automotive parts and sports equipment.

Read on to discover the key advantages of carbon fiber and find out why it is one of the most sought-after materials in modern engineering and design.

What Is Carbon Fiber Material?

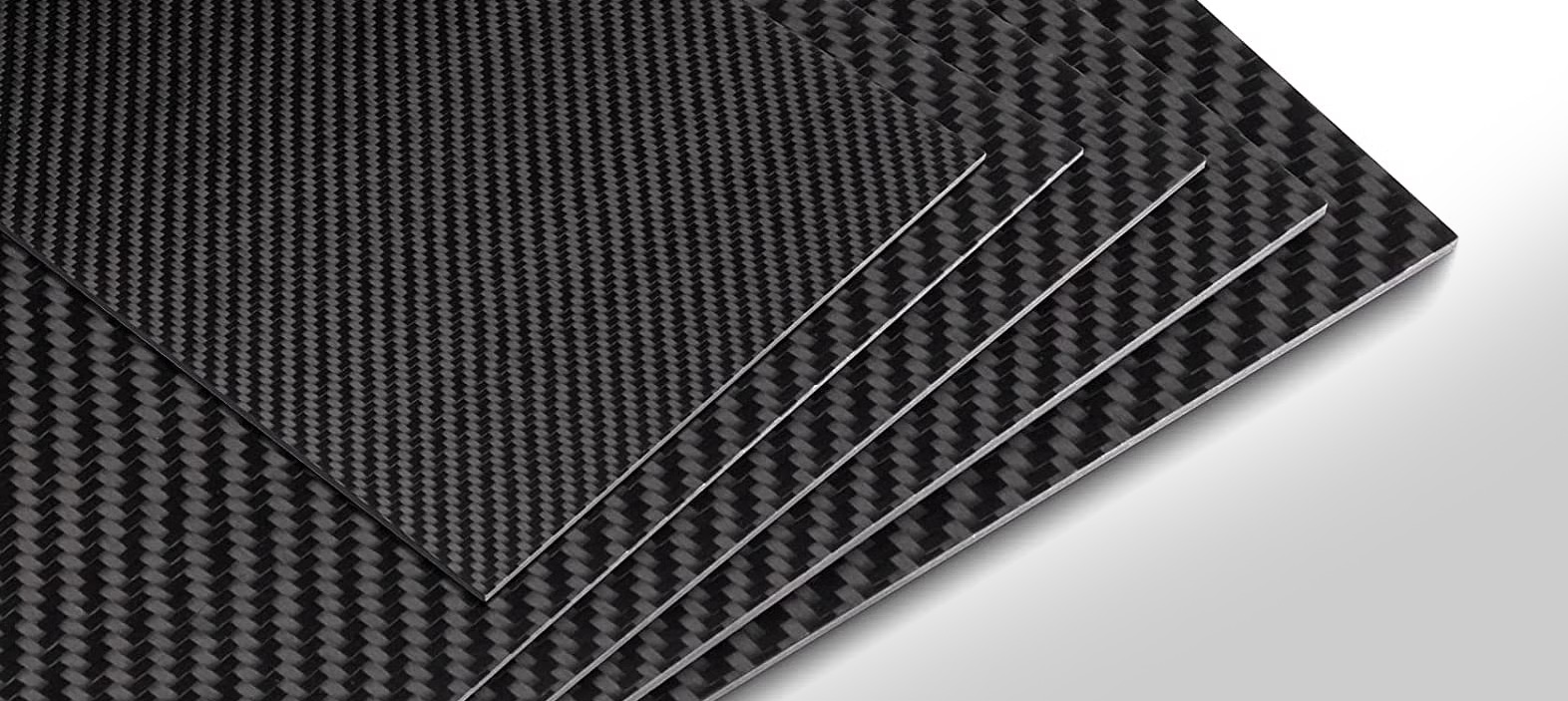

Before we explore its benefits, it’s important to understand what carbon fiber actually is. It is composed of extremely thin strands of carbon atoms that are bonded together in a crystalline structure, resulting in a material that is incredibly strong yet lightweight. These fibers are then woven into fabrics or combined with resin to form carbon fiber reinforced polymers (CFRPs).

This unique composition gives carbon fiber its signature combination of strength, stiffness and lightweight performance—qualities that make it superior to aluminum, steel and plastic in demanding industrial applications.

Unmatched Strength-to-Weight Ratio

One of the most defining advantages of carbon fiber materials is their exceptional strength-to-weight ratio. Despite being five times stronger than steel, carbon fiber weighs only about one-fifth as much. This property enables designers and engineers to create components that are both robust and lightweight, significantly enhancing performance and efficiency.

In automotive engineering, for instance, using carbon fiber in body panels, structural frames, and aerodynamic parts can reduce vehicle mass by up to 50%, leading to faster acceleration, improved fuel efficiency, and better handling. In aerospace and sporting goods, the same advantage translates into greater agility and energy savings.

Excellent corrosion and fatigue resistance

Unlike metals, which rust or fatigue over time, carbon fiber is naturally resistant to corrosion and environmental degradation. It does not oxidize, making it ideal for use in humid, coastal or chemically exposed environments.

In the marine and aviation sectors, this resistance ensures a longer service life and lower maintenance costs. Even when under continuous stress or exposure, carbon fiber maintains its structural integrity, providing a reliable solution for applications that require strength and longevity.

Design Flexibility and Aesthetic Appeal

Another major advantage of carbon fiber is its exceptional design flexibility. As it can be molded into complex shapes without losing strength, carbon fiber enables designers to create advanced structures that combine beauty and performance.

Modern manufacturing techniques allow carbon fiber to be molded into intricate shapes suitable for luxury vehicles, sports equipment and consumer electronics. Its distinctive woven texture also adds a sleek, high-tech aesthetic that has become a visual hallmark of modern engineering.

These design possibilities have made carbon fiber increasingly popular in industries that prioritize both performance and appearance.

Thermal Stability and Low Thermal Expansion

In high-temperature environments, stability and dimensional accuracy are paramount. Carbon fiber materials retain their mechanical properties over a broad temperature spectrum, rendering them ideal for aerospace structures, braking systems, and high-speed motorsport components.

Unlike metals such as aluminum, which expand significantly when heated, carbon fiber's low coefficient of thermal expansion ensures dimensional precision and reliability, even during rapid temperature changes. This stability enables components to perform accurately in challenging operational conditions.

Sustainability and Long-Term Value

Sustainability has become a defining factor in material innovation. Not only does carbon fiber enhance performance, but it also contributes to environmental efficiency by saving energy and reducing emissions. Lightweight structures reduce fuel consumption in vehicles and aircraft, and ongoing advancements in recycling technology are making the material more eco-friendly.

Its long service life minimizes waste and the need for replacement, adding long-term value in industrial and consumer applications. For companies seeking to balance performance with environmental responsibility, carbon fiber represents a forward-looking choice.

Conclusion

The advantages of carbon fiber materials extend far beyond strength and lightness. Its corrosion resistance, design flexibility and sustainability make it an essential component in the development of the next generation of engineering solutions.

As industries continue to seek innovative, energy-efficient and durable solutions, carbon fiber stands out as one of the most advanced and versatile materials available today. Whether used in the aerospace or automotive industries or for consumer products, it offers the perfect balance of performance, durability and modern aesthetics.

Want to learn how carbon fiber is redefining modern engineering? Explore our feature article: Unveiling Carbon Fiber: 10 Surprising Truths and How It's Shaping Our Future.

Supreem Carbon Auto parts new arrivals!

How to Make Carbon Fiber Car Parts?

Carbon Fiber in Everyday Products: Modern Applications & Home Uses | Supreem Carbon

Ducati monster 937 and BM S1000RR 2016+ new arrivals released!

Supreem Carbon: Asya'nın En İyi Profesyonel Motosiklet Karbon Fiber Üretici Markası

Newest Acura NSX Carbon Fiber Hood Vent released!

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

For Products

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

Kawasaki H2/H2R Carbon Fiber Tail Center Fairing

Lamborghini Urus Carbon Fiber Engine Bay Panel

Enhance the visual appearance of your Urus engine bay with these custom carbon fiber engine covers. 100% handmade and a 1:1 copy of the original part, which retains all OEM screw mounting points. Elevate your driving experience with this exquisite addition, showcasing unparalleled craftsmanship and enhancing the allure of your Urus’s engine bay.

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover

Aprilia Tuono V4 Carbon Fiber Exhaust Cover

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram