Unveiling Carbon Fiber: 10 Surprising Truths and How It's Shaping Our Future

Think you know carbon fiber? Think again. Supreem Carbon reveals 10 unexpected facts about this groundbreaking material—how it’s built, where it’s used, and why it’s redefining performance across industries worldwide.

- What Makes Carbon Fiber So Extraordinary?

- 10 Things You Didn't Know About Carbon Fiber

- 1. Carbon Fiber Can Be Repaired—Not Replaced

- 2. Most Raw Carbon Comes From Asia

- 3. All Carbon Fiber Parts Are Handmade

- 4. It's a Composite Material, Not Pure Carbon

- 5. It's Everywhere (Beyond Bikes and Cars)

- 6. Raw Carbon Fibers Are Brittle, but the Composite Is Exceptionally Stiff

- 7. Its Stiffness Can Be Precisely Manipulated

- 8. Not All Carbon Fiber Is Created Equal

- 9. It Has an Exceptionally Long Lifespan

- 10. Petroleum Is a Key Ingredient

- The future of carbon fiber: Lighter, smarter and greener

- Conclusion

- FAQs About Carbon Fiber

In today's relentless pursuit of the ultimate in performance and lightweight design, carbon fiber is a true marvel of material science. From high-performance sports cars to cutting-edge aircraft and the sports equipment we use every day, carbon fiber is everywhere. But what do you really know about this incredible material beyond its reputation for being light and strong? This article will unveil 10 lesser-known facts about carbon fiber and introduce you to pioneering companies such as Supreem Carbon.

What Makes Carbon Fiber So Extraordinary?

Carbon fiber, often dubbed "black gold" for its composition of carbon atoms, has revolutionized numerous industries thanks to its exceptional strength-to-weight ratio, corrosion resistance, and unique aesthetic. It's more than just a material; it represents an innovative leap in engineering. Join us as we delve into the essence of carbon fiber, exploring everything from its complex manufacturing to its astounding applications, offering you a more comprehensive understanding of this material of the future.

10 Things You Didn't Know About Carbon Fiber

1. Carbon Fiber Can Be Repaired—Not Replaced

A common misconception is that once a carbon fiber component is damaged, it's beyond repair. But that's not true! Specialized carbon fiber repair techniques can effectively restore damaged areas, bringing them back to their original structural integrity and performance. This not only extends the product's lifespan but also reduces replacement costs.

2. Most Raw Carbon Comes From Asia

While carbon fiber products are ubiquitous, you might be surprised to learn that the majority of raw carbon fiber (typically polyacrylonitrile, or PAN-based carbon fiber) production is concentrated in Asia. A select few companies master this intricate manufacturing process, forming the core of the global carbon fiber supply chain.

3. All Carbon Fiber Parts Are Handmade

Unlike the automated production of metal components, manufacturing carbon fiber parts is an incredibly precise and labor-intensive process. Each layer of carbon fiber fabric must be meticulously laid by hand according to design specifications. This hands-on approach ensures that every carbon fiber part has a unique "fingerprint" and guarantees the superior performance of the final product. Companies like Supreem Carbon, which specialize in custom carbon fiber auto and motorcycle parts, truly understand the art of hand-laying—it's key to their high-quality products.

4. It's a Composite Material, Not Pure Carbon

The carbon fiber product you hold isn't pure carbon. It's actually a composite material, made by combining carbon fiber filaments with a matrix material, typically epoxy resin. The carbon fibers provide strength and stiffness, while the resin binds the fibers together and protects them from damage, ultimately forming the light and rigid structure we admire.

5. It's Everywhere (Beyond Bikes and Cars)

Carbon fiber's applications extend far beyond high-performance bikes and automobiles. You can find it in

- Aerospace: Aircraft fuselages and wings, significantly reducing weight and improving fuel efficiency.

- Sports Equipment: Golf clubs, tennis rackets, fishing rods, and racing shells, offering lightweight advantages and efficient power transfer.

- Medical Devices: Prosthetics, X-ray equipment.

- Civil Engineering: Bridge reinforcement, structural components in buildings.

- Electronics: Phone cases, laptop shells.

Supreem Carbon's diverse business scope underscores this widespread applicability. They not only provide custom modification parts for cars and motorcycles but also produce carbon fiber home luggage and sports equipment, showcasing the material's vast potential.

6. Raw Carbon Fibers Are Brittle, but the Composite Is Exceptionally Stiff

Surprisingly, individual carbon fibers are extremely thin and brittle. However, when they are combined with a resin matrix and cured, the resulting composite material exhibits incredible stiffness and strength. This synergy is the true source of carbon fiber's power.

7. Its Stiffness Can Be Precisely Manipulated

One of carbon fiber's unique properties is that engineers can precisely control the material's stiffness and flexibility in different directions by adjusting the orientation and number of fiber layers. This "customizable stiffness" is an unparalleled advantage when designing complex structures, particularly in components that require specific directional energy absorption or rigidity. Supreem Carbon's expertise in the technology research and development of carbon fiber composite products leverages this characteristic to optimize the performance of their automotive, motorcycle, and sports equipment parts.

8. Not All Carbon Fiber Is Created Equal

Not all carbon fiber is created equal. Depending on their performance, production processes, and application needs, carbon fibers come in various types and standards (e.g., standard modulus, intermediate modulus, high modulus). They exist in different forms, such as carbon fiber fabric, chopped fibers, or raw fiber bundles, each with its specific use.

9. It Has an Exceptionally Long Lifespan

Compared to metal materials that can corrode or fatigue, carbon fiber boasts exceptional resistance to corrosion and fatigue. This means that under normal use, carbon fiber products can maintain their performance and structural integrity for extended periods, offering an impressive lifespan.

10. Petroleum Is a Key Ingredient

While carbon fiber and "petroleum" might seem unrelated, the polyacrylonitrile (PAN) fiber used to create carbon fiber is often derived from petroleum. This reveals an unexpected connection between carbon fiber production and the traditional petrochemical industry.

The future of carbon fiber: Lighter, smarter and greener

As manufacturing technologies evolve, carbon fiber is entering a new era of innovation.

Automation, 3D prepreg technology and recyclable composites will make carbon fiber more affordable and accessible, expanding its use in electric vehicles, the aerospace industry and consumer products.

Supreem Carbon is at the forefront of this transformation, investing in research and custom development to deliver high-performance carbon fiber solutions tailored for the next generation.

Conclusion

Through these 10 secrets, we hope you've gained a deeper appreciation for the extraordinary material that is carbon fiber. It's more than just a symbol of lightweight design and high performance; it's a masterpiece that blends advanced engineering, exquisite craftsmanship, and chemical ingenuity. From dedicated manufacturers like Supreem Carbon, who are committed to the R&D, design, production, and sale of carbon fiber automotive and motorcycle parts, to giants in the aerospace industry, carbon fiber is shaping our world in unprecedented ways. Understanding carbon fiber means understanding the trends of the future.

Discover how carbon fiber is shaping the future—explore Supreem Carbon’s innovative solutions today.

FAQs About Carbon Fiber

Q1: What makes carbon fiber stronger than steel?

A: Carbon fiber’s strength comes from its tightly bonded atomic structure, offering exceptional tensile strength while being five times lighter than steel.

Q2: Can carbon fiber parts be customized for different vehicles?

A: Absolutely. Supreem Carbon specializes in custom carbon fiber car and motorcycle parts, engineered for precision fitment and optimized performance.

Q3: Is carbon fiber environmentally friendly?

A: While traditional carbon fiber uses petroleum-based materials, new recycling and bio-fiber innovations are making it increasingly sustainable.

Q4: How long does carbon fiber last?

A: With proper care, carbon fiber can last decades. It resists corrosion, fatigue, and UV damage far better than metal or plastic, making it ideal for long-term use in vehicles and industrial parts.

Q5: Can carbon fiber withstand high temperatures?

A: Yes. Carbon fiber can tolerate extremely high temperatures—typically up to 500°C (932°F)—without losing its structural integrity, depending on the resin system used.

Q6: Is carbon fiber recyclable?

A: Traditional recycling is difficult, but advanced pyrolysis and chemical recovery methods now allow the reuse of carbon fibers from old components, supporting sustainable manufacturing.

Q7: What industries use carbon fiber the most?

A: Major sectors include automotive, aerospace, sports, construction, and medical technology. Its lightweight and high-strength properties make it ideal wherever efficiency and performance matter.

You might be interested in the following articles:

-

Understanding the Difference Between Dry and Wet Carbon Fiber

-

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

What Are the Most Common Uses of Carbon Fiber in 2025?

2020+ Toyota Supra A90 Carbon Fiber Engine Cover released!

New Motorcycle Carbon Fiber Parts released!

Carbon Fiber Helmet produced by Supreem Carbon.

Ducati monster 937 and BM S1000RR 2016+ new arrivals released!

Carbon Fibers: What Are They and Why Are They Everywhere? (Production, Properties, and Uses Explained)

For Facotry

When is Supreem carbon founded?

Our company formally established in early 2017.

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

For After-sales Service

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

For Customized Service

What custom customer need to prepare?

1. Send Your Design/Idea/3D drawing.

2. Supplier Quotation Confirmation.

3. Firts Sample Feedback.

Custom Carbon Fiber Wine Bracket

A carbon fiber wine bracket is a premium display solution engineered to combine modern aesthetics with exceptional structural performance. Manufactured from high-strength carbon fiber composite materials, it offers a lightweight yet rigid support system for securely holding and showcasing wine bottles. Its refined texture, durability, and contemporary design make it ideal for luxury retail environments, custom interior projects, and high-end hospitality applications.

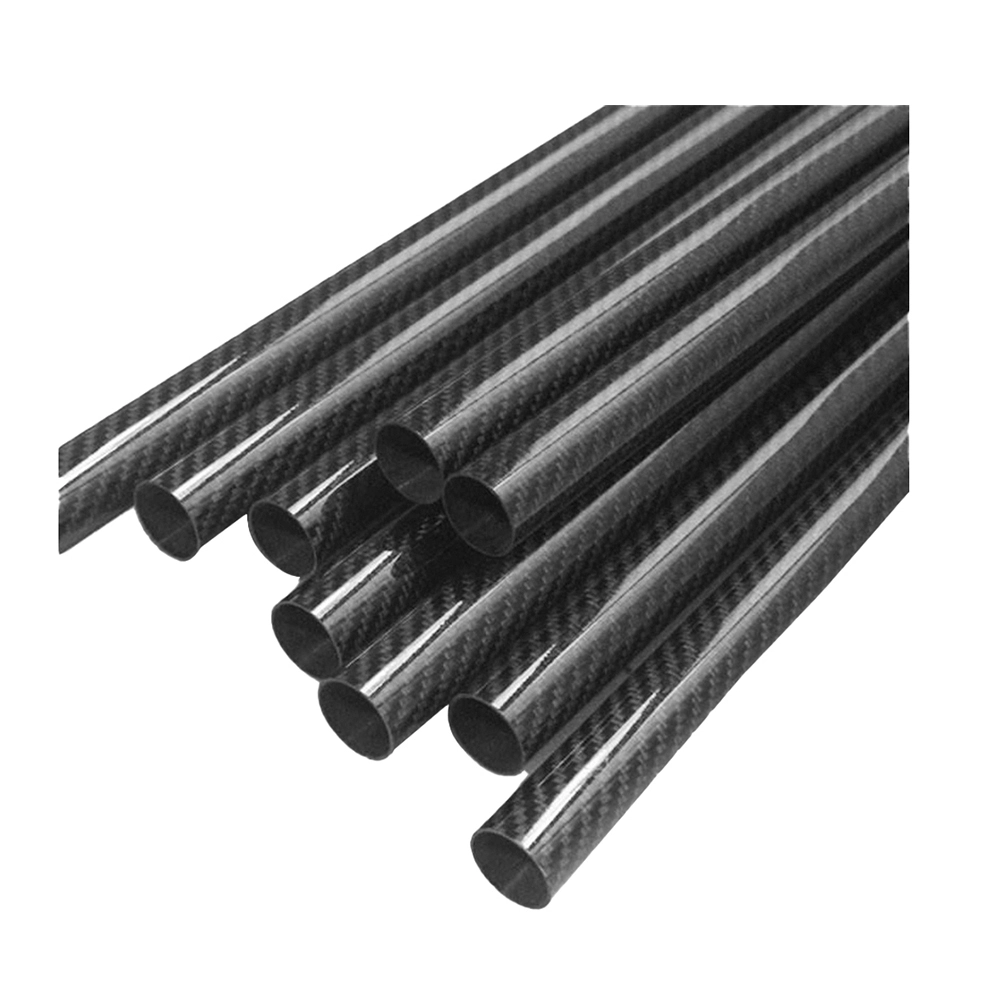

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Custom Carbon Fiber Watch

Carbon fiber is becoming a preferred material in the watch industry thanks to its exceptional strength, lightweight structure, and modern aesthetic. Its advanced performance properties make it ideal for producing durable, high-precision watch components.

Custom Carbon Fiber Drone

Carbon fiber offers several advantages when used in drones (unmanned aerial vehicles, UAVs) due to its unique properties.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram