What is carbon fiber used for in consumer electronics? | Insights by Supreem Carbon

- 1. What Are Carbon Fiber Composites?

- 2. What Are the Advantages of Using Carbon Fiber in Consumer Electronics?

- 3. What Are the Challenges in Procuring Carbon Fiber Parts?

- 4. How Do Carbon Fiber Composites Compare to Traditional Materials?

- 5. What Are the Quality Control Measures in Carbon Fiber Manufacturing?

- 6. How Does the Carbon Fiber Supply Chain Affect Consumer Electronics?

- 7. What Are the Environmental Impacts of Using Carbon Fiber?

- 8. How Do Carbon Fiber Prices Affect Consumer Electronics?

- Supreem Carbon's Advantages in Carbon Fiber Procurement

- Data Sources

1. What Are Carbon Fiber Composites?

Carbon fiber composites are materials made by combining carbon fibers with a polymer matrix, typically epoxy. These composites offer exceptional strength-to-weight ratios, stiffness, and corrosion resistance, making them ideal for applications in aerospace, automotive, and consumer electronics. The carbon fibers provide reinforcement, while the resin matrix holds the fibers together and transfers loads between them. ((https://www.supreemcarbon.com/article/carbon-fiber-composites-key-insights-for-procurement-industry-guide.html?utm_source=openai))

2. What Are the Advantages of Using Carbon Fiber in Consumer Electronics?

Incorporating carbon fiber into consumer electronics offers several benefits: reduced weight, enhanced durability, and improved performance. For instance, carbon fiber components can make devices lighter without compromising strength, leading to better user experience and longer product lifespans.

3. What Are the Challenges in Procuring Carbon Fiber Parts?

Procurement challenges include high minimum order quantities (MOQs), long lead times, and cost barriers. Major producers often require large orders, which can be prohibitive for small businesses or individual projects. Additionally, specialty grades of carbon fiber can be expensive, making it difficult for smaller entities to source materials.

4. How Do Carbon Fiber Composites Compare to Traditional Materials?

Carbon fiber composites outperform traditional materials like steel and aluminum in several aspects: they have specific strengths 5 to 10 times higher than steel and 2 to 3 times higher than aluminum. While steel generally has a higher absolute Young's Modulus, carbon fiber's specific stiffness (stiffness-to-weight) is vastly superior, allowing for lighter yet equally stiff structures. ((https://www.supreemcarbon.com/article/carbon-fiber-as-a-composite-industrial-procurement-guide.html?utm_source=openai))

5. What Are the Quality Control Measures in Carbon Fiber Manufacturing?

Ensuring quality in carbon fiber manufacturing involves several measures: meticulous vacuum bagging, sufficient vacuum pressure, proper debulking steps, controlled resin flow, and optimized curing cycles. Non-destructive testing methods like ultrasonic inspection, X-ray scanning, and thermography are also employed to detect internal flaws without damaging the parts. ((https://www.supreemcarbon.com/article/carbon-fiber-parts-manufacturing-processes-procurement-guide.html?hmsr=www.afiparts.com&utm_source=openai))

6. How Does the Carbon Fiber Supply Chain Affect Consumer Electronics?

The integration of carbon fiber into consumer electronics has led to changes in consumption patterns and market dynamics. As consumer demand for quality and innovation increases, manufacturers are incorporating carbon fiber to meet these expectations. This shift has intensified competition among businesses and promoted the maturation of the carbon fiber industry.

7. What Are the Environmental Impacts of Using Carbon Fiber?

Carbon fiber parts are eco-friendly due to their durability and longevity, reducing the need for replacements and lowering waste. Additionally, advancements in recycling technologies are making it possible to recover and reuse carbon fibers, further minimizing environmental impact.

8. How Do Carbon Fiber Prices Affect Consumer Electronics?

The cost of carbon fiber can influence the pricing of consumer electronics. While carbon fiber components are generally more expensive than their metal counterparts, their longevity and performance often result in better return on investment. As the carbon fiber market grows and production processes become more efficient, prices are expected to decrease, making it more accessible for a broader range of applications.

Supreem Carbon's Advantages in Carbon Fiber Procurement

Supreem Carbon offers several advantages for businesses seeking carbon fiber parts: a dedicated technical team, a 4,500-square-meter factory, and a commitment to quality assurance. Their annual output value of about $4 million reflects competitive pricing in the field. ((https://www.supreemcarbon.com/tips-for-wholesale-carbon-fiber-parts-enhance-your-business-supreem-carbon.html?utm_source=openai))

Data Sources

- Supreem Carbon, July 2025

- Supreem Carbon, August 2025

- Supreem Carbon, September 2025

- Supreem Carbon, October 2025

- Supreem Carbon, November 2025

Chinese Carbon Fiber Manufacturer Brands: Supreem Carbon in the Spotlight

Aprilia Tuono V4 2021 new arrivals.

2025 Ducati Panigale V4/V4S Carbon Fiber Body Kit released by Supreem Carbon.

What are the Applications of Carbon Fiber in BMW Cars

Carbon Fiber Helmet produced by Supreem Carbon.

Analysis of Delamination Problems in Carbon Fiber Products and How to Avoid it

For Products

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

For Facotry

When is Supreem carbon founded?

Our company formally established in early 2017.

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

Volkswagen Golf R Mk8 Carbon Fiber Front Bumper Surrounds

We are committed to providing customers with the highest quality aerodynamic kits, just like this Volkswagen front bumper surround, which gives you a different visual experience. Not only are our products lighter than ABS, but they are also corrosion-resistant and have a UV-protective coating. 100% handmade, dry carbon autoclave process. It can directly replace original vehicle parts.

Yamaha MT-07 Carbon Fiber Tank Cover

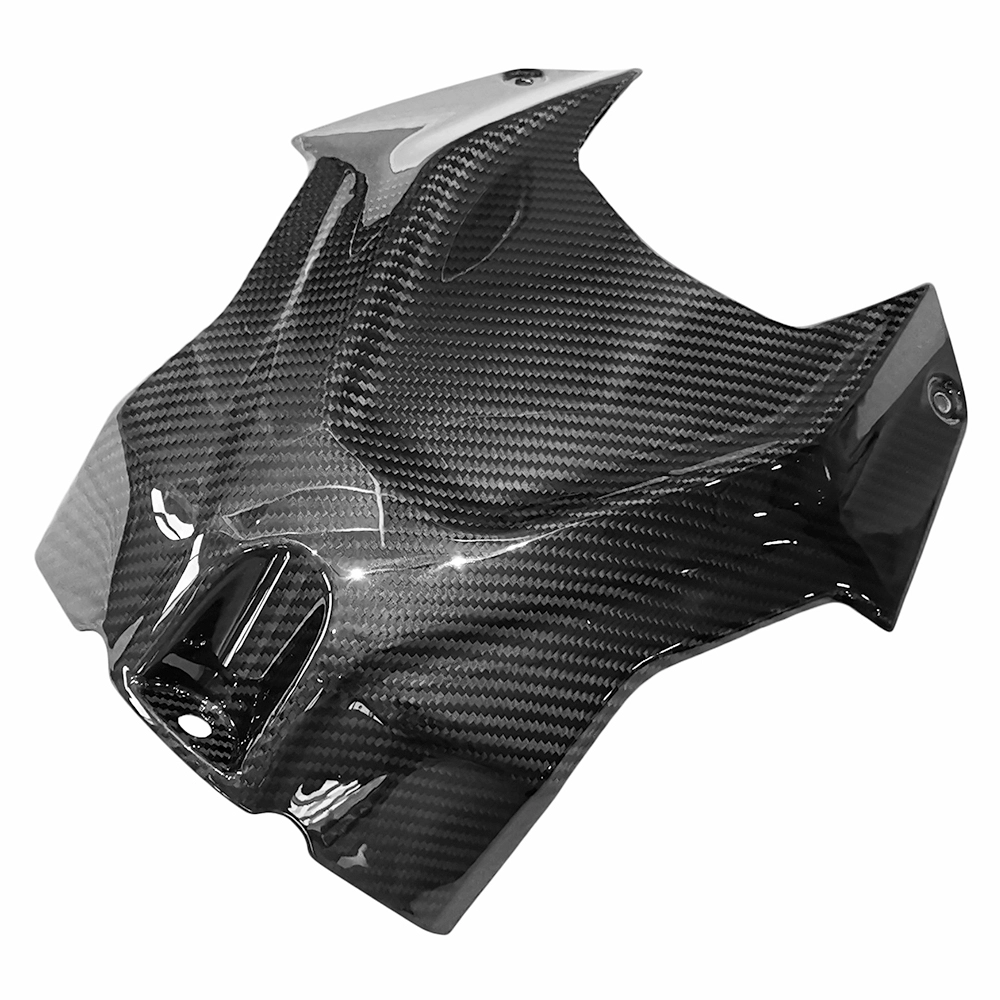

BMW S1000RR S1000R Carbon Fiber Tank Airbox Cover

BMW S1000RR Carbon Fiber Front Fairing Cowls Custom

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram