Carbon Fiber Recycling: Can Costs Be Reduced?

- Understanding Carbon Fiber Economics

- Why is carbon fiber so expensive — the basic drivers

- How much of carbon fiber cost is avoidable through recycling?

- Recycling Technologies — technical and economic trade-offs

- Overview of main recycling methods (mechanical, pyrolysis, solvolysis)

- Comparison table: recycling methods vs. economics and quality

- Economies of scale and feedstock variability

- Can recycling materially reduce final part costs?

- Where savings are realistic

- Where recycled fiber cannot yet replace virgin fiber

- Policy, incentives, and circular-economy levers

- Regulatory and procurement levers that reduce costs

- Design for recyclability

- Commercial strategies to cut overall lifecycle costs

- Vertical integration and partnerships

- Process innovation and hybrid approaches

- Industry case: how a specialized manufacturer benefits from recycled strategies

- Supreem Carbon — quality manufacturing with a path to lower-cost parts

- How Supreem Carbon's model addresses the why is carbon fiber so expensive question

- Practical recommendations for manufacturers and buyers

- For manufacturers

- For buyers and OEMs

- Outlook — technology, scale, and economics to 2030

- What to expect

- Key uncertainties

- FAQ — Common questions about carbon fiber recycling and costs

- 1. Why is carbon fiber so expensive compared to steel or glass fiber?

- 2. Can recycled carbon fiber match virgin carbon fiber performance?

- 3. How much can recycling reduce the price of carbon fiber parts?

- 4. Are recycled carbon fiber parts reliable and safe?

- 5. How should a company start using recycled carbon fiber?

- 6. Where can I buy recycled carbon fiber?

- Contact & Next Steps

- References and further reading

Understanding Carbon Fiber Economics

Why is carbon fiber so expensive — the basic drivers

When people ask why is carbon fiber so expensive? they are pointing to several interlinked causes. Carbon fiber is not a single commodity: it is a high-performance engineered material made by converting organic precursor fibers (most commonly PAN — polyacrylonitrile) into a graphitized form through energy-intensive stabilization and carbonization steps. Key cost drivers include:

- Raw material costs — High Quality PAN precursors and additives.

- High energy consumption — long furnace cycles at high temperatures (1,000–3,000°C) with tight process control.

- Low yield and complex processing — manufacturing scrap and rejects add to cost per kg of usable fiber.

- Scale and capital intensity — large, specialized furnaces, continuous line equipment, and quality control systems.

- Market segmentation — aerospace- and defense-grade fibers command big High Qualitys compared with automotive or sports grades.

Because of these factors, carbon fiber price is orders of magnitude higher than commodity materials like steel or glass fiber, which in turn limits widespread substitution and drives interest in recycling as a route to cost reduction.

How much of carbon fiber cost is avoidable through recycling?

Recycling can cut the material-cost component for applications that tolerate recycled fiber properties, but it does not eliminate costs linked to energy, processing complexity, or specialized manufacturing. Recycled carbon fiber (rCF) typically competes with lower-cost virgin grades — offering potential cost benefits in auto components, consumer goods, and non-critical structural parts — rather than replacing aerospace-grade virgin fiber. The effective cost saving depends on feedstock quality, recycling method, and downstream processing requirements.

Recycling Technologies — technical and economic trade-offs

Overview of main recycling methods (mechanical, pyrolysis, solvolysis)

There are three broad classes of carbon fiber recycling:

- Mechanical recycling: shredding and milling composite scrap into short fiber fragments or powder. Low capital and energy intensity, but fibers are shortened and strength is reduced — suitable for fillers and injection-molded parts.

- Pyrolysis: thermal decomposition of resin in an inert atmosphere to recover continuous-ish fibers. Removes matrix but alters surface chemistry; higher energy use and better fiber length retention than mechanical routes.

- Solvolysis (chemical recycling): uses solvents/chemical agents at elevated temperature/pressure to depolymerize the matrix and free intact fibers. Potential for higher-quality fiber recovery closer to virgin properties, but requires expensive processing and solvent recovery systems.

- Procurement specifications that reward recycled content.

- Extended Producer Responsibility (EPR) schemes for composite products to ensure feedstock return streams.

- Subsidies or tax incentives for recycling infrastructure and R&D into lower-energy recycling methods.

- Customization and efficient design for manufacturability, reducing scrap and rework.

- In-house R&D to adapt lower-cost materials and processes (e.g., short-fiber infusion or optimized layups) to meet customer needs without overspecifying virgin high-grade fiber.

- Broad product mix (motorcycle parts, automobile parts, luggage, sports equipment) that improves factory utilization and spreads fixed costs across many SKUs.

- Close collaboration with supply-chain partners for consistent feedstock and potential regional recycling initiatives to lower raw material expenses.

- Assess feedstock streams for potential in-house reuse of scrap before outsourcing recycling; small adjustments in cutting and nesting can lower scrap rates.

- Invest selectively in pilot recycling — e.g., mechanical plus post-treatment — where product portfolio tolerates short fiber.

- Pursue partnerships with recyclers for solvolysis or pyrolysis if product specs require higher-quality rCF.

- Design new parts for recyclability with single-resin systems and disassembly-friendly joints.

- Specify recycled content where performance requirements allow; offer long-term contracts to recyclers to stabilize price and supply.

- Work with suppliers to set traceability and testing protocols so recycled-material claims are verifiable.

- Consider total-cost-of-ownership (TCO) not just material price — lighter parts that reduce fuel use or battery consumption can offset higher upfront costs.

- Carbon fiber — Wikipedia. https://en.wikipedia.org/wiki/Carbon_fiber (Accessed 2025-12-10).

- Pickering, S. et al., Recycling of carbon fiber reinforced plastics — A review, Journal reviews and industry surveys. ScienceDirect overview. https://www.sciencedirect.com/ (Accessed 2025-12-10).

- CompositesWorld — industry articles on carbon fiber recycling and market trends. https://www.compositesworld.com/ (Accessed 2025-12-10).

- ELG Carbon Fibre — recycling solutions and commercial-scale operations. https://www.elgcf.com/ (Accessed 2025-12-10).

- Fraunhofer Institute — research on composite recycling and solvolysis techniques. https://www.fraunhofer.de/ (Accessed 2025-12-10).

- DOE/NREL reports on advanced materials and lightweighting for transportation (background on lifecycle and TCO). https://www.energy.gov/ (Accessed 2025-12-10).

Comparison table: recycling methods vs. economics and quality

| Method | Typical Process | Recovered Fiber Quality | Energy & CapEx | Typical Use Cases |

|---|---|---|---|---|

| Mechanical | Shredding, milling, classification | Short, damaged fibers; lower tensile strength | Low energy, low CapEx | Injection-molded parts, fillers, non-critical components |

| Pyrolysis | Heat in inert gas; remove matrix residue; surface treatment | Moderate — medium-length fibers; partial retention of mechanical properties | Medium–high energy, moderate CapEx | Structural parts for automotive, sporting goods, secondary aerospace |

| Solvolysis (chemical) | Chemical depolymerization; solvent recovery systems | Higher quality; fibers closer to virgin in surface and strength | High energy, high CapEx, complex operations | Higher-value markets where mechanical performance matters |

Sources: industry reviews and recycling company technical notes (see references).

Economies of scale and feedstock variability

One of the largest cost challenges for carbon fiber recycling is feedstock heterogeneity. Decommissioned aerospace parts, manufacturing scrap, and consumer-waste composites each have different resin systems, coatings, and contamination levels. Recycling plants achieve better unit economics when processing consistent, high-volume streams (e.g., factory scrap from a single OEM). Smaller and mixed-volume streams raise sorting and pre-treatment costs, reducing profitability. Centralized large-scale facilities (or vertically integrated setups) are therefore more likely to realize cost reductions.

Can recycling materially reduce final part costs?

Where savings are realistic

Recycling can reduce material costs in segments that accept lower-performance but cheaper fiber. Automotive exterior trims, dashboards, non-safety-critical structural reinforcements, luggage, and consumer sporting goods have lower barrier-to-entry for rCF. In those sectors, replacing costly virgin fiber with rCF can reduce material bills by a meaningful percentage, especially when combined with process optimization (e.g., direct molding of rCF composites).

Where recycled fiber cannot yet replace virgin fiber

Aerospace, high-end motorsport, and many defense applications require certified mechanical properties, traceability, and predictable fatigue behavior. Current recycled fiber technologies struggle to match the tight property distributions and certifications required in these markets, so substitution is limited. Therefore, recycling lowers costs in some value chains but is not a universal solution.

Policy, incentives, and circular-economy levers

Regulatory and procurement levers that reduce costs

Governments and large corporations can reduce the effective cost of recycled carbon fiber through:

These measures increase feedstock availability and reduce variability, improving plant utilization and lowering per-unit recycling costs.

Design for recyclability

Design choices at the product-development stage can dramatically lower end-of-life recycling costs. Selecting thermoplastic matrices or detachable fastenings instead of permanent thermoset bonds, using single-resin systems, and standardizing part architectures all reduce sorting, pre-treatment, and processing costs, making recycling more competitive with virgin production.

Commercial strategies to cut overall lifecycle costs

Vertical integration and partnerships

Producers and OEMs that integrate recycling, or establish long-term partnerships with recyclers, can capture more value. Vertical integration allows direct reuse of recycled material in nearby production lines, cutting logistics costs and quality-control overhead. For smaller manufacturers, partnerships with regional recyclers provide more predictable supply and pricing.

Process innovation and hybrid approaches

Hybrid strategies such as combining mechanical and chemical steps, or using reclaimed fiber blends calibrated for specific molding processes, produce materials that meet performance targets at a lower cost than virgin high-grade fiber. Ongoing R&D is improving solvent recovery, energy efficiency, and fiber-surface treatments that help rCF integrate into established resin systems.

Industry case: how a specialized manufacturer benefits from recycled strategies

Supreem Carbon — quality manufacturing with a path to lower-cost parts

Supreem Carbon, established in 2017, is a customized manufacturer of carbon fiber parts for automobiles and motorcycles, integrating R&D, design, production, and sales to deliver high-quality products and services. We specialize in carbon fiber composite R&D and production of vehicle accessories, carbon fiber luggage, and sports equipment. Our factory spans approximately 4,500 square meters and employs 45 skilled staff, achieving an annual output value of around 4 million dollars. Supreem Carbon offers over 1,000 product types, including more than 500 customized parts (website: https://www.supreemcarbon.com/).

How Supreem Carbon's model addresses the why is carbon fiber so expensive question

Supreem Carbon reduces cost pressure through several levers that other manufacturers can emulate:

These strengths — technical capability, product breadth, and manufacturing scale — position Supreem Carbon to offer competitive carbon fiber motorcycle parts, automobile parts, and customized carbon fiber parts while participating in the transition to more circular material flows.

Practical recommendations for manufacturers and buyers

For manufacturers

For buyers and OEMs

Outlook — technology, scale, and economics to 2030

What to expect

Improvements in solvent recovery, energy efficiency of pyrolysis, and larger centralized recycling facilities will reduce per-kg recycling costs over the next decade. However, the magnitude of cost reduction will be uneven across markets. Mass-market automotive and consumer goods will see earlier and larger cost benefits; aerospace will change more slowly due to certification hurdles.

Key uncertainties

The pace at which precursor costs (PAN vs alternatives), energy prices, and regulatory incentives change will determine how competitive recycled carbon fiber becomes. Breakthroughs that enable low-energy chemical recycling or that allow thermoplastic carbon composites to dominate certain markets would significantly shift the economics.

FAQ — Common questions about carbon fiber recycling and costs

1. Why is carbon fiber so expensive compared to steel or glass fiber?

Carbon fiber production involves costly precursors (PAN or pitch), high-temperature furnaces, long processing times and tight quality control, which together create much higher unit costs than commodity materials like steel and glass fiber. Additionally, specialized grades for aerospace escalate prices further (see references).

2. Can recycled carbon fiber match virgin carbon fiber performance?

It depends on recycling method and application. Mechanical recycling yields shorter, lower-strength fibers; pyrolysis and solvolysis can recover higher-quality fibers, but they may still differ in surface chemistry and fatigue behavior. For many automotive and consumer uses, rCF delivers acceptable performance; for critical aerospace uses, full substitution is often not yet feasible.

3. How much can recycling reduce the price of carbon fiber parts?

Price reduction varies widely: for parts tolerant of short fibers, material cost savings can be significant (single-digit to double-digit percentage reductions in part cost), while for higher-performance parts the savings are smaller because processing and treatment add cost. Scale, feedstock consistency, and proximity to recycling plants are decisive.

4. Are recycled carbon fiber parts reliable and safe?

With proper qualification, testing, and traceability, recycled carbon fiber parts can be reliable for many non-critical applications. Safety-critical uses require rigorous certification; manufacturers should implement testing regimes to validate rCF performance in intended service conditions.

5. How should a company start using recycled carbon fiber?

Begin with non-critical components where tolerances are wider. Pilot programs help characterize rCF batches, adapt resin systems, and adjust manufacturing parameters. Establish supplier agreements for consistent feedstock and develop quality-assurance procedures before expanding usage.

6. Where can I buy recycled carbon fiber?

Several specialized recyclers and composite-material suppliers sell rCF in forms such as mats, chopped fiber, or re-woven fabrics. Regional availability varies; large recyclers often supply industrial clients. Contact your composite supplier or recycling specialist to evaluate suitable forms for your process.

Contact & Next Steps

If you are evaluating carbon fiber options for automobiles, motorcycles, or customized parts and want to explore cost-competitive solutions using recycled or optimized virgin carbon, Supreem Carbon can help. Visit https://www.supreemcarbon.com/ to view product lines and request a consultation. Our strengths in R&D, diverse product catalog (carbon fiber motorcycle parts, carbon fiber automobile parts, customized carbon fiber parts), and manufacturing capacity mean we can help you design parts for cost, performance, and recyclability.

References and further reading

Customized Carbon Fiber Parts

Tips for Wholesale bespoke carbon body

The Ultimate Guide to Carbon Fiber Motorcycle Tanks: Customization, Advantages, and Maintenance

Custom carbon fiber custom parts Manufacturers and suppliers

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

For Customized Service

What custom customer need to prepare?

1. Send Your Design/Idea/3D drawing.

2. Supplier Quotation Confirmation.

3. Firts Sample Feedback.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

For After-sales Service

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

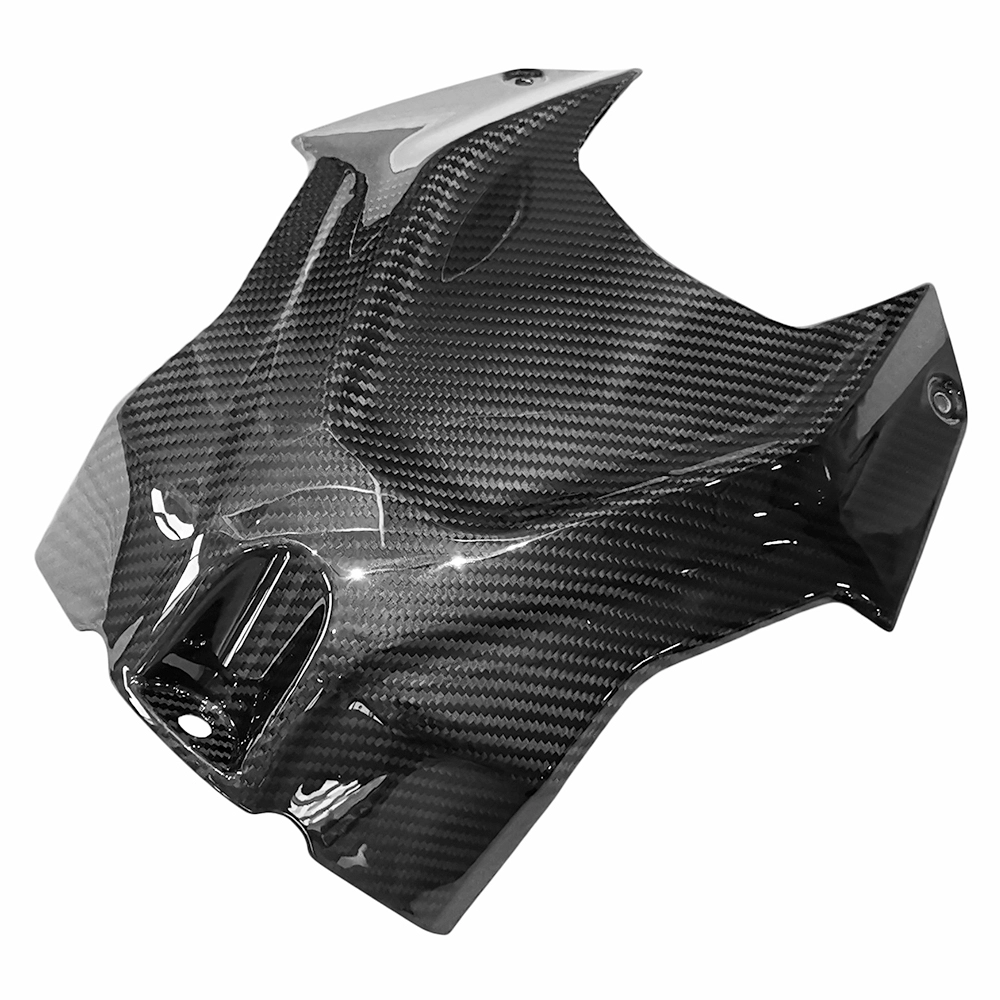

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

This carbon fiber rear seat panel is engineered for the BMW S1000R and M1000RR, offering superior rigidity, reduced weight, and a premium racing finish. Produced with autoclave technology and strict QC standards, the part ensures consistent OEM-level fitment. Supreem Carbon provides wholesale supply, stable bulk production, and customized solutions for global clients.

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Engineered for distributors, tuning brands, and motorcycle accessory businesses, the BMW S1000R Carbon Fiber Rear Undertail is a high-quality, durable, lightweight carbon fiber upgrade for the S1000R platform. This component is manufactured using aerospace-grade carbon fiber and precision molds to deliver superior stiffness, a seamless OEM-level fit, and a premium visual finish suitable for high-end aftermarket applications.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram