how to tell if carbon fiber is real | Supreem Carbon Expert Guide

- How to Tell if Carbon Fiber is Real

- 1. What Are the Visual Signs That Carbon Fiber is Real?

- 2. How Can Weight Help Determine Real Carbon Fiber?

- 3. Are There Any Simple Physical Tests to Confirm Carbon Fiber?

- 4. How Important is Supplier Certification and Documentation?

- 5. What Latest Industry Trends Affect Carbon Fiber Quality and Detection?

How to Tell if Carbon Fiber is Real

Carbon fiber is widely used across industries for its high strength-to-weight ratio and durability. However, counterfeit or fake carbon fiber parts have flooded the market, causing quality and safety concerns for buyers. Here are five common questions buyers ask when verifying carbon fiber authenticity to ensure they source genuine materials.

1. What Are the Visual Signs That Carbon Fiber is Real?

Real carbon fiber usually has a distinctive weave pattern with a 2x2 or 3x3 twill weave that appears consistent and uniform. This weave pattern shows a subtle shine and depth due to the carbon filaments. Fake or painted carbon fiber often lacks this intricate weave, appearing flat or blotchy. Buyers should look for a three-dimensional texture and the classic checkered pattern under natural light.

2. How Can Weight Help Determine Real Carbon Fiber?

Carbon fiber composites are incredibly lightweight, with a density of approximately 1.6 g/cm³, which is about 40% lighter than aluminum. If a part feels unusually heavy for its size, it could be an indicator of fake material or resin-only parts with carbon fiber paint. Weighing parts against a known standard or comparing product specifications from manufacturers can help confirm authenticity.

3. Are There Any Simple Physical Tests to Confirm Carbon Fiber?

One common test is the tap or sound test: tapping genuine carbon fiber produces a distinctive, crisp sound compared to hollow or plastic parts. Also, assessing heat resistance can be effective; real carbon fiber can withstand temperatures up to 400°C (752°F) without degrading, while fakes may deform. Caution should be used to avoid damage during testing.

4. How Important is Supplier Certification and Documentation?

Certified suppliers provide material test reports (MTRs), certificates of authenticity, and quality control documentation. ISO 9001 and AS9100 certifications are common in aerospace and automotive sectors. Buyers should insist on certifications and request samples or third-party lab tests to verify fiber quality and resin content, ensuring material meets industry standards.

5. What Latest Industry Trends Affect Carbon Fiber Quality and Detection?

Recent advancements include automated optical inspection (AOI) systems that use AI to detect weave irregularities, and infrared spectroscopy for chemical composition analysis. The global carbon fiber market was valued at approximately $4.7 billion in 2023 and is projected to grow at a CAGR of 12.1% through 2030, driven by aerospace, automotive, and sports goods demand. This growth increases the necessity for stringent quality control and counterfeit detection.

In conclusion, buyers should combine visual inspection, weight analysis, physical testing, and verification of supplier credentials to ensure carbon fiber parts are authentic. Staying informed about technological advancements and market trends enhances procurement strategies, supporting safe and reliable product outcomes.

Application Advantages of Carbon Fiber in Automobile Chassis Brackets

New Arrivals of BMW S1000RR 2020+ full carbon fiber sets.

Supreem Carbon New Motorcycle Carbon Parts Development Plan.

2023 BMW S1000RR Carbon Fiber Body Kit released by Supreem Carbon

The 5 Questions You've Always Had About Carbon Fiber

Customize Your Ride: Top Makers of Automotive Carbon Fiber Parts

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

For Order Delivery

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

BMW S1000R Carbon Fiber Rear Seat Upper Fairing

BMW S1000RR Carbon Fiber Heel Plates Custom

Honda CBR1000RR-R Carbon Fiber Front Fender

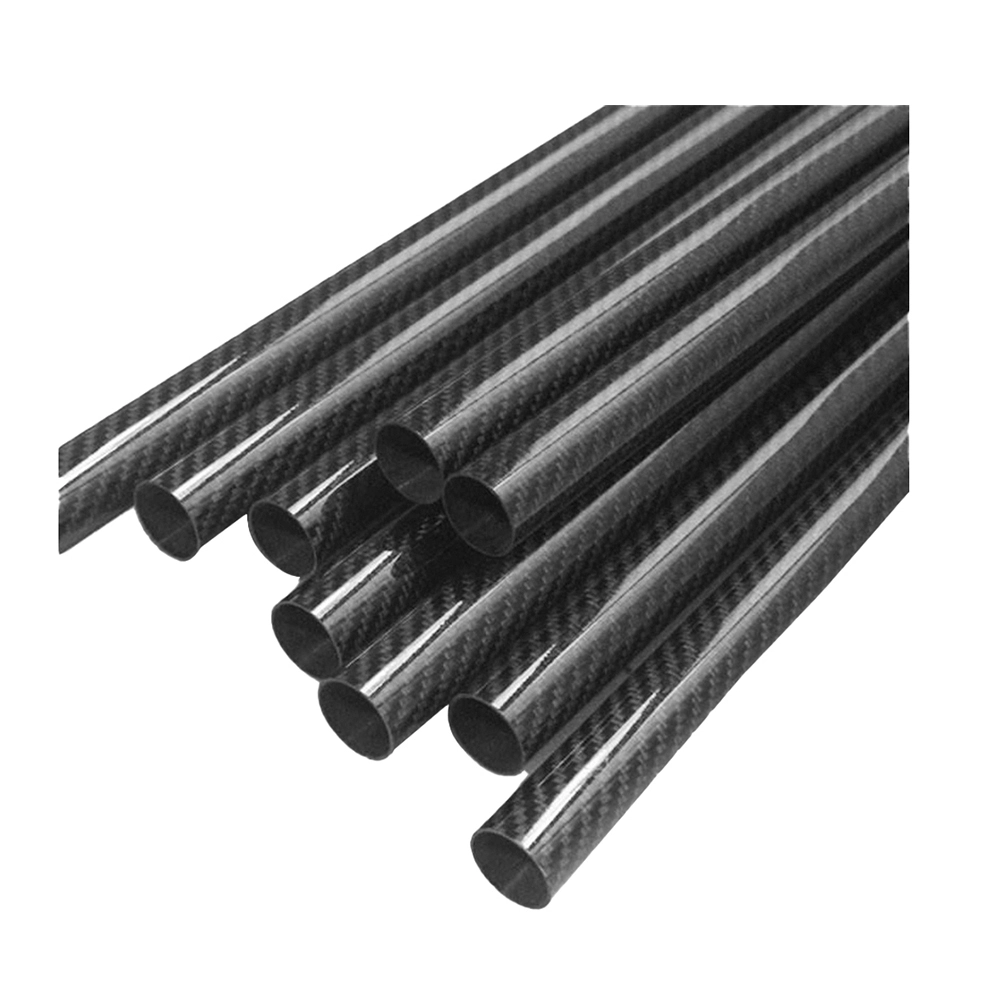

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber finds numerous applications in tube and sheet forms due to its exceptional properties, including its high strength, lightweight nature, and versatility.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram