Carbon Fiber Products: Uses & Applications - Supreem Carbon

What Products Are Made From Carbon Fiber? A Deep Dive into Applications

What is Carbon Fiber?

Before diving into the products themselves, let's briefly define carbon fiber. It's a material consisting of extremely thin fibers of carbon atoms bonded together. This structure gives carbon fiber exceptional tensile strength – meaning its ability to resist being pulled apart – while remaining remarkably lightweight. This unique combination of strength and lightness is what makes it so valuable in various industries.

What Products Are Made from Carbon Fiber? A Comprehensive Overview

The applications of carbon fiber are vast and constantly expanding. Here's a look at some key areas:

Aerospace and Defense:

* Aircraft Components: Carbon fiber is crucial in building lightweight yet strong aircraft parts, including fuselages, wings, and control surfaces. This reduces fuel consumption and improves aircraft performance. Its use in reducing weight is paramount for improving fuel efficiency.

* Missiles and Rockets: The high strength-to-weight ratio of carbon fiber is also vital in the construction of missiles and rockets, ensuring that they can withstand the intense stresses of launch and flight.

* Satellites: Lightweight, durable carbon fiber composites are used in satellite structures, helping to reduce launch costs and improve satellite lifespan.

Automotive Industry:

* High-Performance Vehicles: Carbon fiber is a staple in high-performance and luxury vehicles. It's used to create lightweight body panels, chassis components, and other structural elements, boosting acceleration and handling.

* Electric Vehicles: The lightweight nature of carbon fiber is especially beneficial in electric vehicles, as it helps to extend the range by reducing the overall vehicle weight.

Sporting Goods:

* Bicycle Frames: Carbon fiber bicycles are prized for their stiffness, responsiveness, and low weight, providing a competitive edge to cyclists.

* Golf Clubs: Lightweight and strong carbon fiber shafts in golf clubs improve swing speed and accuracy.

* Tennis Rackets: Carbon fiber rackets offer superior power and control.

* Fishing Rods: Lightweight yet durable carbon fiber fishing rods provide enhanced sensitivity and casting performance.

Medical Applications:

* Prosthetics: Carbon fiber's strength and biocompatibility make it suitable for use in prosthetics and orthotics, providing lightweight and durable support.

* Surgical Instruments: Its high strength-to-weight ratio allows for the creation of precision surgical instruments that are both lightweight and robust.

Other Applications:

* Wind Turbine Blades: The use of carbon fiber in wind turbine blades allows for the creation of larger, more efficient blades, leading to increased energy generation.

* Industrial Machinery: Carbon fiber's strength and durability make it suitable for components in industrial machinery where high strength and low weight are required.

Frequently Asked Questions (FAQs)

Q: Is carbon fiber recyclable? A: While not easily recyclable in the same way as metals, research is ongoing into developing effective carbon fiber recycling processes. The complexities involved in separating the fibers and resins from composites pose a challenge.

Q: How is carbon fiber made? A: Carbon fiber is manufactured through a process involving the pyrolysis of polyacrylonitrile (PAN) or rayon fibers. This involves heating the fibers to high temperatures in an inert atmosphere, converting them into carbon fibers.

Q: Is carbon fiber expensive? A: Yes, carbon fiber is generally more expensive than traditional materials like steel or aluminum, due to the complex manufacturing process. However, its superior properties often justify the cost in specific applications.

Q: How strong is carbon fiber? A: Carbon fiber boasts exceptionally high tensile strength, meaning it is highly resistant to being pulled apart. Its strength-to-weight ratio far surpasses that of many other materials.

Q: What are the limitations of carbon fiber? A: While incredibly strong in tension, carbon fiber can be relatively brittle under compression. It is also susceptible to damage from impacts, and its high cost remains a barrier to wider adoption in some areas.

This exploration of the multifaceted applications of carbon fiber highlights its significance across diverse industries. From the skies to the sporting field and beyond, its unique properties continue to drive innovation and performance enhancement.

High-Performance Carbon Fibers by Supreem Carbon

Enhance Your Vehicle and Lifestyle with Custom Carbon Fiber Pieces from Supreem Carbon

Custom carbon fiber motorcycle wheels Manufacturers and suppliers

Exploring Carbon Fiber in Automotive | Supreem Carbon

For Customized Service

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

For Products

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

For Facotry

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

For After-sales Service

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

Yamaha R1 Carbon Fiber Side Fairings

Introducing the Supreem Carbon Fiber Long Side Panels for Yamaha R1. Crafted with precision and expertise, this front side fairing is designed to elevate the performance and aesthetics of your R1. Made from high-quality carbon fiber, this fairing is not only lightweight but also incredibly durable, providing optimal protection for your motorcycle.

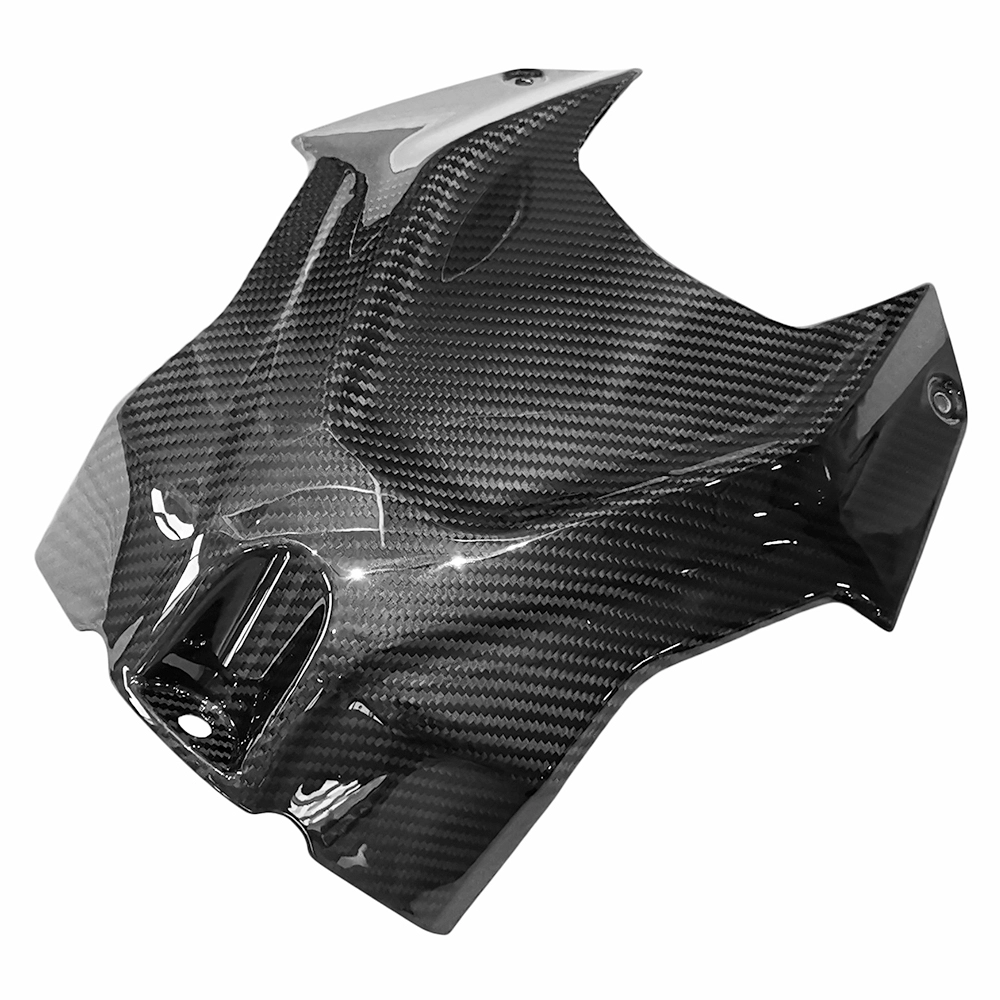

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

This carbon fiber rear seat panel is engineered for the BMW S1000R and M1000RR, offering superior rigidity, reduced weight, and a premium racing finish. Produced with autoclave technology and strict QC standards, the part ensures consistent OEM-level fitment. Supreem Carbon provides wholesale supply, stable bulk production, and customized solutions for global clients.

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Engineered for distributors, tuning brands, and motorcycle accessory businesses, the BMW S1000R Carbon Fiber Rear Undertail is a high-quality, durable, lightweight carbon fiber upgrade for the S1000R platform. This component is manufactured using aerospace-grade carbon fiber and precision molds to deliver superior stiffness, a seamless OEM-level fit, and a premium visual finish suitable for high-end aftermarket applications.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram