Is carbon fiber expensive? | Supreem Carbon Expert Guide

- Is Carbon Fiber Expensive?

- What Factors Influence the Cost of Carbon Fiber?

- How Does Carbon Fiber Compare to Other Materials in Cost-Benefit?

- What Are Current Market Trends Affecting Carbon Fiber Prices?

- How to Procure Carbon Fiber Parts Cost-Effectively?

- What Quality and Technical Considerations Are Crucial When Buying Carbon Fiber Parts?

Is Carbon Fiber Expensive?

Carbon fiber is often perceived as expensive compared to traditional materials like steel or aluminum. Typically, carbon fiber material costs range from $10 to $30 per pound, while fiberglass costs around $2 to $5 per pound, and aluminum is roughly $1.50 to $3.50 per pound. The higher price of carbon fiber stems from its complex manufacturing process, raw material costs, and specialized handling. Despite its cost, carbon fiber offers superior strength-to-weight ratio, corrosion resistance, and design flexibility.

What Factors Influence the Cost of Carbon Fiber?

The price of carbon fiber can vary widely depending on the grade, type (e.g., PAN-based or pitch-based), and production scale. Aerospace-grade carbon fibers, which have higher tensile strength and modulus, cost more than lower-grade fibers used in automotive or sporting goods. Other costs include resin systems, labor-intensive layup and curing processes, and quality control. Economies of scale and advancements in production technology are gradually lowering costs.

How Does Carbon Fiber Compare to Other Materials in Cost-Benefit?

While carbon fiber’s upfront costs are higher, its benefits often translate into long-term savings. For example, in automotive applications, carbon fiber enables significant weight reduction leading to improved fuel efficiency and performance. In aerospace, its high strength and lightweight reduce fuel consumption. Additionally, carbon fiber parts have longer lifespans and lower maintenance costs. When considering the total lifecycle cost, carbon fiber can be economically justified despite the High Quality price.

What Are Current Market Trends Affecting Carbon Fiber Prices?

Recent market analysis shows that global carbon fiber demand is increasing in sectors like electric vehicles (EVs), renewable energy (wind turbine blades), and aerospace. The global carbon fiber market was valued at approximately $3.92 billion in 2023, with an expected CAGR of around 12% through 2030. Supply chain challenges and raw material scarcity can cause price fluctuations. However, investments in newer carbon fiber production facilities, recycling technologies, and alternative precursor materials are helping stabilize prices.

How to Procure Carbon Fiber Parts Cost-Effectively?

Industry buyers can optimize procurement by partnering with suppliers who offer flexible order sizes and integrating design for manufacturability (DFM) to minimize waste. Bulk purchasing and long-term contracts may secure better pricing. Additionally, exploring hybrid materials (carbon fiber combined with other composites) and recycled carbon fiber options can reduce costs. Rigorous supplier qualification ensures quality and consistency, avoiding costly reworks.

What Quality and Technical Considerations Are Crucial When Buying Carbon Fiber Parts?

Procurement professionals should focus on fiber type, tow size, tensile strength, and modulus to match application requirements. It’s important to check for certifications such as ISO standards and aerospace qualifications if applicable. Testing for void content, fiber orientation, and resin compatibility ensures performance. Collaboration with engineers during design and specification phases ensures the selected carbon fiber meets mechanical, thermal, and environmental demands.

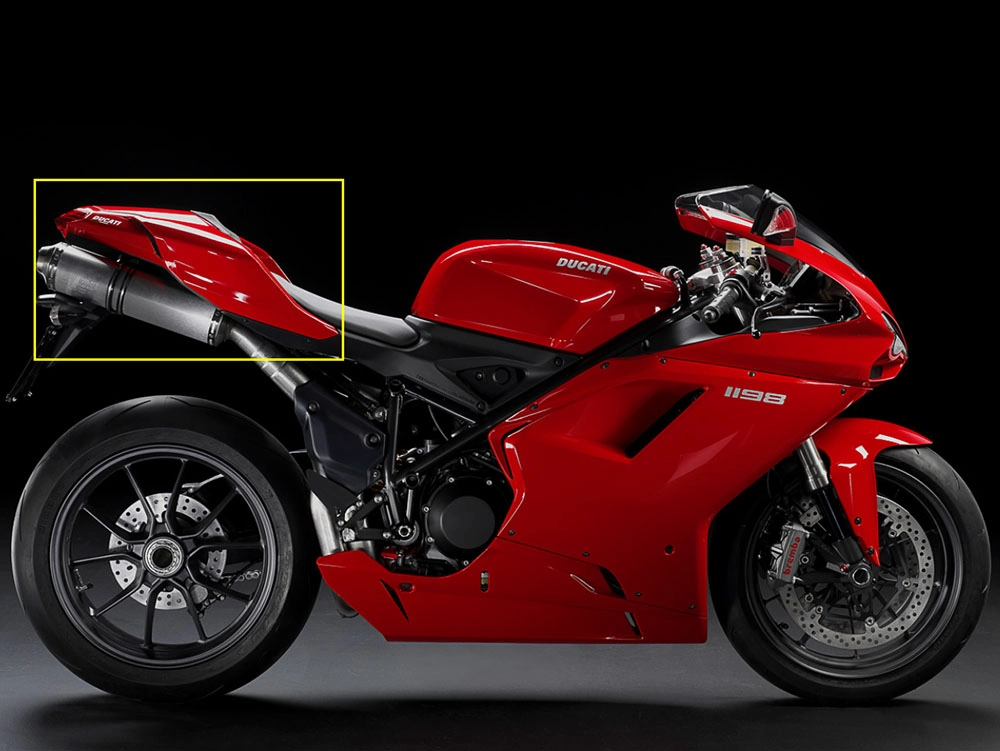

Fabricante de fibra de carbono para motocicletas de alta calidad de China

New arrivals of Honda CBR1000RR-R!

Лучший производитель углеродного волокна в Китае

Supreem Carbon new arrivals released!

New Motorcycle Carbon Fiber Parts released!

Research on the Causes of Yellowing of Carbon Fiber Products.

For Customized Service

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

BMW S1000R Carbon Fiber Rear Seat Upper Fairing

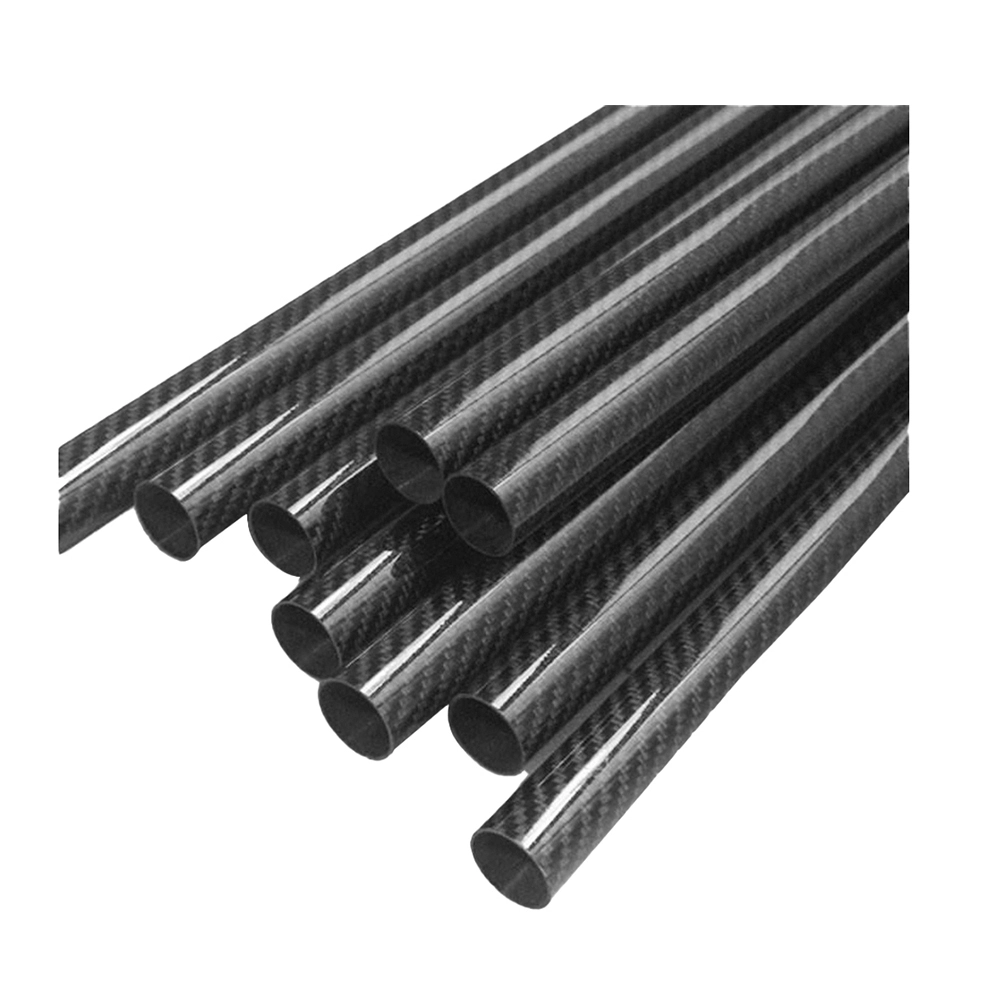

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Yamaha MT-07 Carbon Fiber Tank Cover

Kawasaki ZX10R Carbon Fiber Front Side Panel

Introducing the Supreem Carbon Fiber Front Side Fairing for the Kawasaki ZX10R. Crafted with precision and expertise, it is designed to enhance the performance and appearance of your motorcycle. Made from high-quality carbon fiber, it is lightweight yet incredibly durable, providing optimal protection for your motorcycle.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram