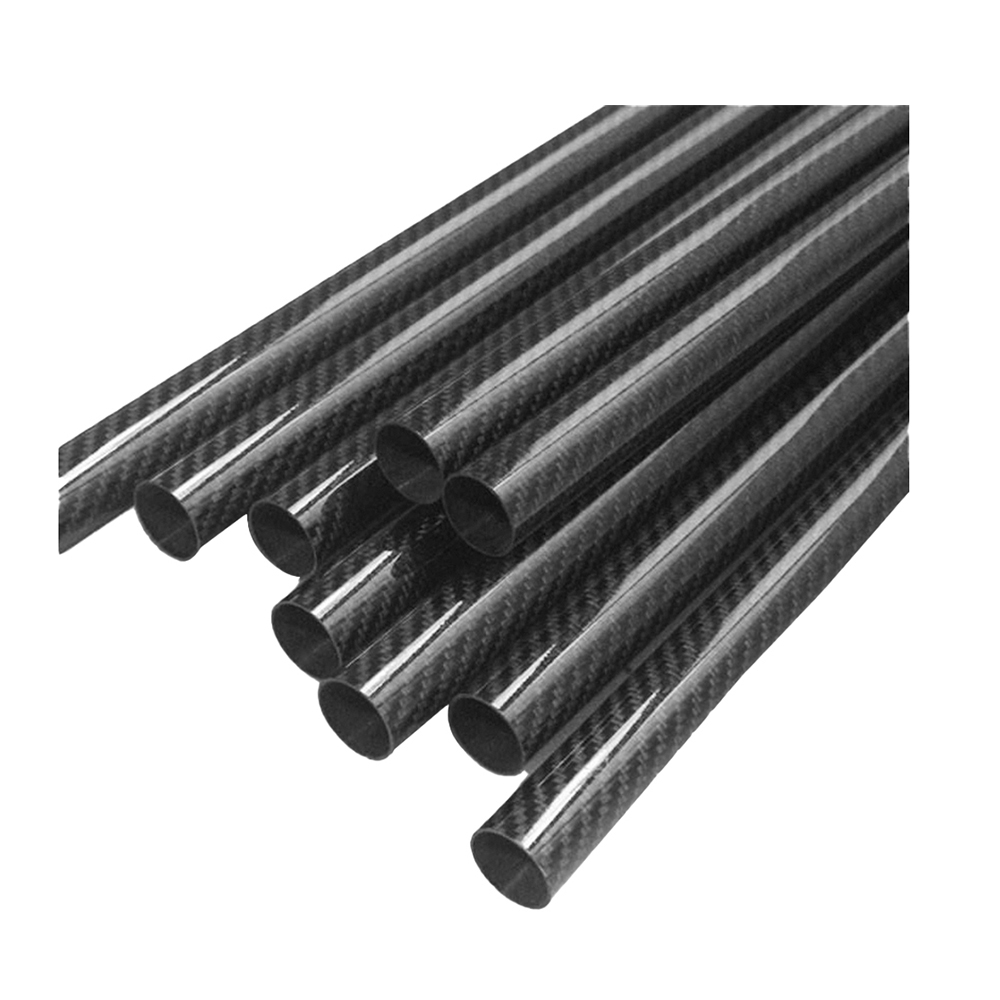

Aerospace Grade Carbon Fiber Tubes

Aerospace Grade Carbon Fiber Tubes — Precision, Strength, Lightness

Why Choose Aerospace Grade Carbon Fiber Tubes

Our aerospace grade carbon fiber tubes combine exceptional stiffness-to-weight ratio, fatigue resistance, and dimensional stability—ideal for demanding applications where every gram and millimeter matter. Designed for engineers and performance enthusiasts, these tubes deliver superior load-bearing capacity while minimizing weight for automobiles, motorcycles, UAVs, and aerospace subsystems.

Advanced Materials & Manufacturing

Supreem Carbon uses high-modulus fibers and aerospace-certified resins to manufacture tubes that meet rigorous performance standards. Our process integrates automated layup, precision curing, and strict quality controls to ensure consistent wall thickness, true roundness, and repeatable mechanical properties across batches.

Customization & Application Flexibility

We specialize in bespoke solutions: custom diameters, wall thicknesses, surface finishes, end treatments, and integrated fittings. Whether you need lightweight drive shafts, structural spars, or decorative yet functional trim, our carbon fiber tubes can be tailored to meet design briefs and regulatory requirements.

Quality Assurance & Traceability

Every tube is inspected and tested for tensile strength, modulus, and concentricity. Our traceable production records and material certifications make Supreem Carbon a reliable partner for R&D, prototypes, and full-scale production runs requiring aerospace-grade documentation.

Manufacturing Capacity & Expertise

Founded in 2017, Supreem Carbon operates a 4,500 m² factory with 45 skilled production and technical staff, yielding an annual output value near $4M. We offer more than 1,000 products and 500+ customized parts, backed by continuous R&D in carbon fiber composites.

About Supreem Carbon & How to Order

Supreem Carbon integrates R&D, design, production, and sales to deliver High Quality carbon fiber solutions. Our vision is to be the world’s leading carbon fiber products manufacturer. Explore aerospace grade carbon fiber tubes and full customization services at https://www.supreemcarbon.com/ or contact us to discuss prototypes, tooling, and volume production.

aerospace grade carbon fiber tubes Display

- Extensive Production Experience

Over 10 years of experience in carbon fiber products production, we are well-versed in various processes and production technologies to guarantee product quality stable and consistency.

- Project consultation

Our designers will provide customers with project feasibility analysis and quotations based on the ideas and design concepts or drawings provided by customers.

- Free samples

For specific product development projects, we will provide customers with a set of free samples.

- Logo and packaging

Add your personal touch with custom branding options and premium packaging, making every product uniquely yours.

- Weight

Engineered to be lightweight for effortless handling and portability without compromising on durability.

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

How many employees of Supreem carbon?

We have over 50 employees, including over 40 skilled workers, 3 R&D designers, and 5 QC professionals and so on.

Are you parts have UV protected?

Absolutely! We use multiple layers of premium quality automotive clear (or matt) coats on our products, which ensure that they will remain super pretty for years to come.

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Yamaha R1/R1M Carbon Fiber Rear Fender Hugger Mudguard

Yamaha R1/R1M Carbon Fiber Rear Fender Hugger Mudguard

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover2025 Ducati Panigale V4/V4S Carbon Fiber Body Kit released by Supreem Carbon.

Redefining Lightweight Performance and Aesthetic Precision in Motorcycle Design

Supreem Carbon Cross-Country Mountain Bike Seat: The Ultimate Lightweight Carbon Fiber Upgrade

Discover ultimate performance with Supreem Carbon's Carbon Fiber Cross Country Mountain Bike Seat. Expertly crafted for avid cyclists, this lightweight seat is designed to enhance your biking experience with superior comfort and durability. Made from premium carbon fiber parts, it offers exceptional strength while minimizing weight. Perfect for cross-country adventures, this seat embodies quality and innovation that Supreem Carbon is renowned for. Elevate your ride and explore the world with confidence. Optimize your biking performance with our top-tier carbon fiber seat today.

Xiaomi SU7 Carbon Fiber Aerodynamic Body Kit – Supreem Carbon Testing Feedback

In this article, we share Supreem Carbon’s in-depth testing feedback on the Xiaomi SU7 carbon fiber aerodynamic body kit. From the front splitter and side skirts to the rear wing and aerodynamic fender covers, we evaluate how the carbon fiber components perform in terms of weight reduction, structural integrity, and visual appeal. Learn how these upgrades affect the vehicle’s performance, safety, and aesthetics.

Analysis of Delamination Problems in Carbon Fiber Products and How to Avoid it

Discover insights into delamination in carbon fiber products. Our analysis explores common causes of carbon fiber delamination and effective strategies to prevent it, ensuring the longevity and reliability of your products. Enhance your understanding of delamination challenges and solutions by reading our comprehensive guide tailored for industry professionals.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram