Premium Carbon Fiber Board Manufacturers for Automotive & Motorcycle Parts

Leading Carbon Fiber Board Manufacturers - Supreem Carbon

Expertise in Customized Carbon Fiber Solutions

Since 2017, Supreem Carbon has established itself as a top-tier carbon fiber board manufacturer, specializing in tailor-made carbon fiber parts for automobiles and motorcycles. We combine in-depth research & development with innovative design and precision manufacturing, ensuring every product meets the highest standards of quality and performance.

Comprehensive Product Range and Advanced Manufacturing

Our 4,500 square meter production facility houses 45 skilled technicians, delivering an annual output valued at approximately $4 million. With over 1,000 product types—including 500+ customized carbon fiber parts—we cater to diverse automotive and motorcycle needs, including carbon fiber luggage, accessories, and sports equipment.

Why Choose Supreem Carbon for Carbon Fiber Boards?

As trusted carbon fiber board manufacturers, we pride ourselves on exceptional craftsmanship, cutting-edge composite technology, and customized solutions tailored to each client's specifications. Our commitment to innovation and quality drives us toward our vision of becoming the world's leading carbon fiber products manufacturer.

Partner with Supreem Carbon

Whether you're seeking high-performance carbon fiber boards or bespoke parts, Supreem Carbon delivers excellence and reliability. Explore our extensive catalog and experience superior materials engineered for durability, lightweight strength, and sleek aesthetics.

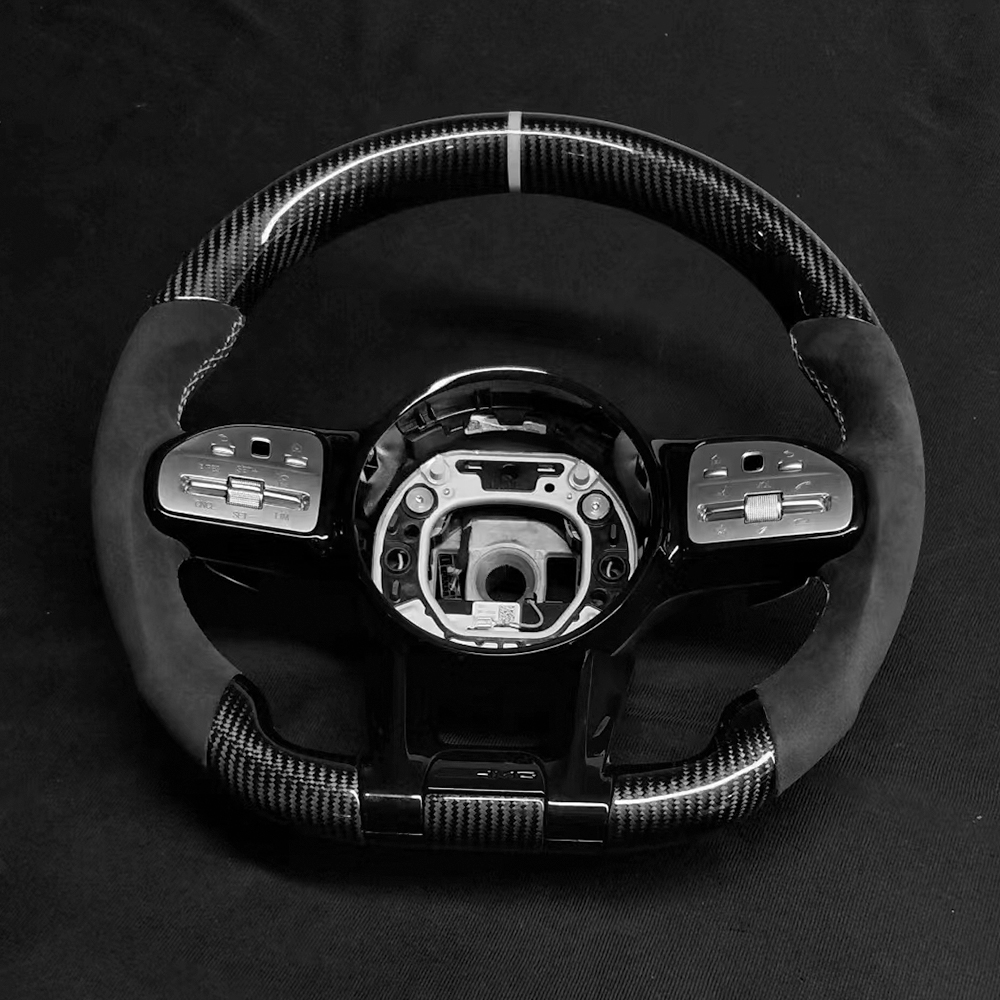

carbon fiber board manufacturers Display

- Professional development suggestions

Our engineers will provide customers with professional development suggestions based on different products and different uses.

- Free mold opening

For some projects developed in cooperation with customers, molds will be provided to customers free of charge according to the specific conditions of the project.

- Project consultation

Our designers will provide customers with project feasibility analysis and quotations based on the ideas and design concepts or drawings provided by customers.

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Yamaha R1/R1M Carbon Fiber Rear Fender Hugger Mudguard

Yamaha R1/R1M Carbon Fiber Rear Fender Hugger Mudguard

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover2025 Ducati Panigale V4/V4S Carbon Fiber Body Kit released by Supreem Carbon.

Redefining Lightweight Performance and Aesthetic Precision in Motorcycle Design

Supreem Carbon Cross-Country Mountain Bike Seat: The Ultimate Lightweight Carbon Fiber Upgrade

Discover ultimate performance with Supreem Carbon's Carbon Fiber Cross Country Mountain Bike Seat. Expertly crafted for avid cyclists, this lightweight seat is designed to enhance your biking experience with superior comfort and durability. Made from premium carbon fiber parts, it offers exceptional strength while minimizing weight. Perfect for cross-country adventures, this seat embodies quality and innovation that Supreem Carbon is renowned for. Elevate your ride and explore the world with confidence. Optimize your biking performance with our top-tier carbon fiber seat today.

Xiaomi SU7 Carbon Fiber Aerodynamic Body Kit – Supreem Carbon Testing Feedback

In this article, we share Supreem Carbon’s in-depth testing feedback on the Xiaomi SU7 carbon fiber aerodynamic body kit. From the front splitter and side skirts to the rear wing and aerodynamic fender covers, we evaluate how the carbon fiber components perform in terms of weight reduction, structural integrity, and visual appeal. Learn how these upgrades affect the vehicle’s performance, safety, and aesthetics.

Analysis of Delamination Problems in Carbon Fiber Products and How to Avoid it

Discover insights into delamination in carbon fiber products. Our analysis explores common causes of carbon fiber delamination and effective strategies to prevent it, ensuring the longevity and reliability of your products. Enhance your understanding of delamination challenges and solutions by reading our comprehensive guide tailored for industry professionals.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram