Is Carbon Fiber Electrically Conductive | Supreem Carbon Expert Guide

Renowned for its exceptional strength-to-weight ratio, carbon fibre also possesses significant electrical conductivity – a crucial yet often misunderstood property for many advanced applications. This blog post demystifies the electrical characteristics of carbon fibre by comparing its conductivity to that of traditional metals and detailing the critical factors that influence its performance, such as fibre type, orientation and resin chemistry. It also explores key industrial applications such as electromagnetic interference (EMI) shielding, lightning strike protection and static dissipation. Professionals in the aerospace, automotive and electronics industries need to understand how to engineer these properties in order to optimise high-performance composite solutions for their specific needs.

- Is Carbon Fiber Electrically Conductive? Understanding Its Nature

- How Does Carbon Fiber's Conductivity Compare to Metals?

- What Factors Influence Carbon Fiber Electrical Conductivity?

- Key Applications and Design Considerations for Conductive Carbon Fiber Parts

- Can Carbon Fiber's Electrical Properties Be Engineered?

- Supreem Carbon: Precision in Advanced Composites

Is Carbon Fiber Electrically Conductive? Understanding Its Nature

For decades, carbon fiber has been celebrated for revolutionizing industries with its unparalleled strength-to-weight properties. However, a less discussed but equally critical characteristic for many applications is its electrical conductivity. The short answer is: Yes, carbon fiber is electrically conductive. Unlike many traditional composite materials that are electrical insulators (like fiberglass), carbon fiber derives its conductivity from the graphite-like structure of its constituent fibers.

Each carbon fiber filament is composed primarily of carbon atoms arranged in a hexagonal lattice, similar to graphite. These delocalized electrons in the graphite structure enable the flow of electric current. However, it's crucial to understand that while conductive, carbon fiber composites do not conduct electricity with the same efficiency as metals like copper or aluminum. Typically, the electrical resistivity of individual carbon fibers along their axis can range from approximately 1.5 x 10-5 to 1.5 x 10-4 Ohm-cm. When these fibers are embedded in a polymer matrix to form a composite laminate, the overall conductivity of the material becomes anisotropic (direction-dependent) and is generally lower than that of the raw fibers due to the insulating resin and fiber contact resistance. Typical in-plane conductivity of a well-designed carbon fiber laminate might be in the range of 102 to 103 S/m (Siemens per meter), while through-thickness conductivity is significantly lower, often 10-1 to 101 S/m.

How Does Carbon Fiber's Conductivity Compare to Metals?

While carbon fiber is conductive, its electrical performance is orders of magnitude less than that of highly conductive metals. To put it into perspective:

- Copper: Approximately 5.96 x 107 S/m

- Aluminum: Approximately 3.5 x 107 S/m

- Carbon Fiber Composite (in-plane): Typically 102 to 103 S/m

This means copper is roughly 100,000 times more conductive than a typical carbon fiber composite in the fiber direction. Therefore, carbon fiber composites are generally not used for primary electrical wiring or high-current power transmission where metals excel. Instead, their conductivity is leveraged for applications where a certain level of conductivity is required without the weight or corrosion drawbacks of metals, or for specific functions like electromagnetic interference (EMI) shielding or lightning strike protection.

What Factors Influence Carbon Fiber Electrical Conductivity?

The electrical conductivity of carbon fiber parts is not a fixed value; it can vary significantly based on several factors:

- Fiber Type: Different grades of carbon fiber (e.g., standard modulus, intermediate modulus, high modulus) possess varying degrees of graphitization and purity, which directly impacts their inherent conductivity. Higher modulus fibers generally exhibit better conductivity.

- Fiber Volume Fraction: The higher the percentage of carbon fiber by volume within the composite, the more pathways exist for current flow, thus increasing overall conductivity.

- Fiber Orientation/Layup: As conductivity is significantly higher along the fiber axis, a unidirectional (UD) layup will be highly conductive in one direction, whereas a quasi-isotropic layup (fibers oriented in multiple directions) will offer more balanced but lower overall conductivity across the plane. Through-thickness conductivity is generally the lowest due to the insulating resin-rich layers between plies.

- Resin System: While the polymer matrix (epoxy, polyester, etc.) is typically an electrical insulator, its properties and how it wets out the fibers can affect the contact resistance between fibers and, consequently, the composite's overall conductivity. Some resins can also be made more conductive with additives.

- Processing Method: Factors like fiber wet-out, void content, and curing pressure can influence the continuity of the conductive network within the composite, impacting its electrical performance.

Key Applications and Design Considerations for Conductive Carbon Fiber Parts

Understanding carbon fiber's conductivity is paramount for designing high-performance composite parts for various industries:

- Electromagnetic Interference (EMI) Shielding: Carbon fiber composites are effective at attenuating electromagnetic waves, making them ideal for enclosures in aerospace, electronics, and telecommunications to protect sensitive equipment from EMI/RFI (radio frequency interference). Their conductivity allows them to reflect and absorb electromagnetic radiation.

- Lightning Strike Protection (LSP): In aircraft and wind turbine blades, carbon fiber structures can conduct lightning current away from sensitive areas, mitigating damage. While inherently conductive, additional measures like metallic meshes (e.g., copper or aluminum) or conductive paints are often incorporated on the surface to enhance LSP, as carbon fiber alone may not always safely dissipate the extremely high currents of a direct lightning strike without localized damage.

- Static Dissipation and Grounding: Carbon fiber parts can be used to prevent the buildup of static electricity in sensitive environments (e.g., fuel systems, cleanrooms, electronics manufacturing) by providing a path to ground. This is crucial for safety and preventing electrostatic discharge (ESD) damage.

- Resistive Heating Elements: In some niche applications, the inherent resistance of carbon fiber can be leveraged to create lightweight heating elements.

When designing with conductive carbon fiber, engineers must consider how electrical connections will be made, the path of current flow, and the potential for galvanic corrosion if carbon fiber is in direct contact with certain metals in the presence of an electrolyte.

Can Carbon Fiber's Electrical Properties Be Engineered?

Absolutely. For applications requiring specific levels of conductivity, manufacturers can engineer carbon fiber composites in several ways:

- Conductive Fillers in Resin: Incorporating conductive nanoparticles like carbon nanotubes (CNTs), graphene, or specialized carbon black into the polymer resin matrix can significantly enhance the through-thickness and interlaminar conductivity.

- Metallic Meshes or Fabrics: Embedding thin layers of copper, aluminum, or nickel mesh or fabric between carbon fiber plies is a common method to boost conductivity, particularly for LSP and EMI shielding.

- Conductive Surface Coatings: Applying conductive paints, metallic coatings (e.g., nickel plating), or highly conductive films to the surface of the composite part can create a conductive pathway where needed.

- Fiber Selection and Orientation: Choosing higher conductivity carbon fiber grades and optimizing fiber layup to maximize conductivity in the desired direction.

By leveraging these techniques, carbon fiber composite manufacturers can tailor the electrical properties of parts to meet the precise requirements of diverse applications, moving beyond simple structural benefits.

Supreem Carbon: Precision in Advanced Composites

At Supreem Carbon, we understand that the future of high-performance parts lies not just in their mechanical strength but also in their engineered functionalities. Our expertise in carbon fiber manufacturing allows us to precisely control and optimize the electrical conductivity of our composite components. Whether your application demands superior EMI shielding, robust lightning strike protection, or reliable static dissipation, Supreem Carbon leverages advanced material science, proprietary processing techniques, and a deep understanding of fiber architecture to deliver custom-engineered solutions. We provide materials with consistent, verifiable electrical properties, ensuring your parts perform exactly as designed, enhancing safety, reliability, and functionality across aerospace, automotive, electronics, and industrial sectors. Partner with Supreem Carbon for your next generation of intelligent, high-performance composite parts.

Supreem carbon Auto part new arrivals!

Fabricante de fibra de carbono para motocicletas de alta calidad de China

New arrivals---Carbon Fiber Slam Panel Replacement for BMW M3 M4

What Are the Most Common Uses of Carbon Fiber in 2025?

Лучший производитель углеродного волокна в Китае

Upgrade Your Ride: Custom Motorcycle Carbon Fiber Parts by Supreem Carbon

For After-sales Service

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

For Facotry

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

For Products

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

For Order Delivery

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

Honda CBR1000RR-R Carbon Fiber Front Fender

Ducati Monster 937 Carbon Fiber Sprocket Cover

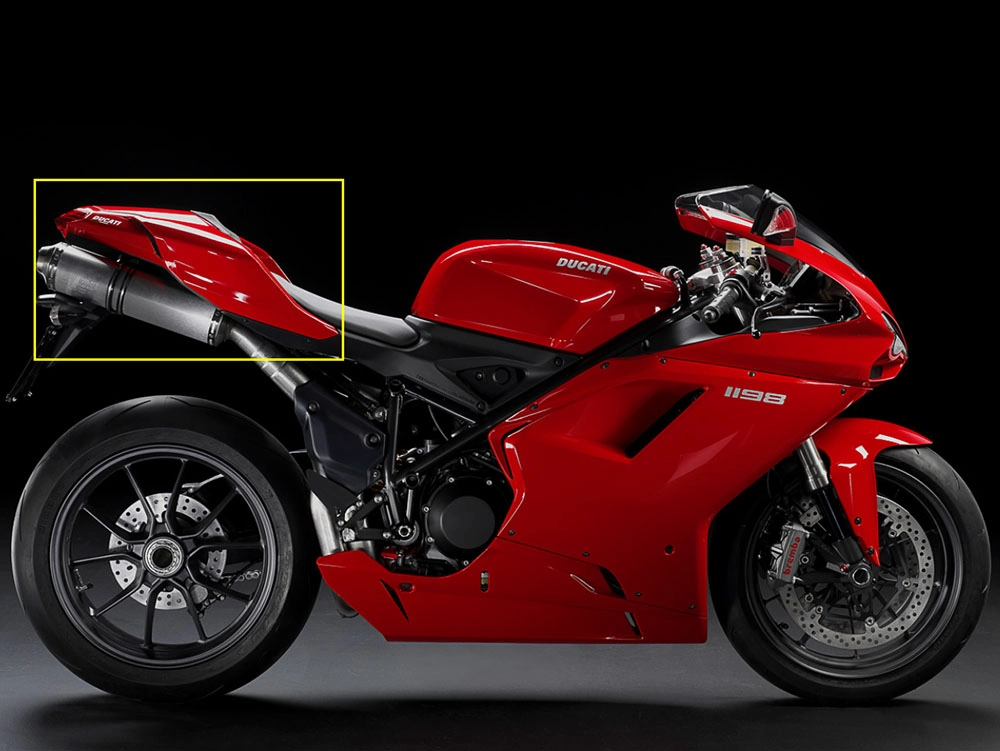

Kawasaki H2/H2R Carbon Fiber Tail Center Fairing

Aucra NSX Carbon Fiber Nose Beak Replacement

Give your 2017+ NSX front a more unique look with our direct replacement carbon fiber Nose Beak. Each piece is carefully hand-crafted for a perfect fitment in any NSX.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram