Does carbon fiber improve performance? | Supreem Carbon Guide

Does Carbon Fiber Improve Performance? | Supreem Carbon

This article explores the key performance advantages of using carbon fiber in various applications, addressing common questions and concerns of professionals in the field. We examine how carbon fiber's unique properties translate to tangible improvements.

Superior Strength-to-Weight Ratio

* Lightweight Design: Carbon fiber boasts an exceptionally high strength-to-weight ratio, significantly lighter than traditional materials like steel or aluminum. This reduction in weight directly translates to improved performance. (Source: ASM Handbook, Volume 21: Composites)

* Increased Efficiency: In automotive applications, this lighter weight reduces inertia, leading to improved acceleration, braking, and handling. (Source: SAE International Journal of Passenger Cars - Mechanical Systems)

* Enhanced Fuel Economy: The reduced weight also contributes to better fuel economy, a crucial factor in today's market. (Source: US Department of Energy, Vehicle Technologies Office)

High Stiffness and Modulus

* Improved Structural Integrity: Carbon fiber exhibits remarkably high stiffness and modulus, resulting in increased structural rigidity. This means less deflection under load, crucial for high-performance applications. (Source: Materials Science and Engineering R: Reports)

* Enhanced Precision: In aerospace and robotics, this enhanced stiffness ensures greater precision and control. (Source: Journal of Composite Materials)

* Reduced Vibrations: The inherent stiffness also reduces vibrations and noise, improving the overall performance and feel of the final product.

Fatigue Resistance and Durability

* Extended Lifespan: Carbon fiber parts exhibit superior fatigue resistance compared to many metals, leading to a longer lifespan and reduced maintenance needs. (Source: Composites Science and Technology)

* Reliable Performance: This durability translates to reliable performance even under demanding operating conditions.

* Cost-Effectiveness (Long Term): Although initial costs might be higher, the extended lifespan and reduced maintenance often lead to long-term cost-effectiveness.

Tailored Properties Through Design

* Customization Options: The properties of carbon fiber components can be precisely tailored through the design and manufacturing process, optimizing performance for specific applications.

* Advanced Manufacturing Techniques: Techniques like prepreg layup and autoclave curing allow for precise control over fiber orientation and resin content, maximizing performance characteristics. (Source: Handbook of Composites)

* Optimization for Specific Needs: This allows for the creation of parts that are optimized for strength, stiffness, or weight reduction depending on the requirements.

Applications Across Industries

* Aerospace: Carbon fiber is extensively used in aircraft structures and components due to its superior strength-to-weight ratio and fatigue resistance.

* Automotive: Its lightweight nature improves vehicle performance and fuel efficiency.

* Sporting Goods: Carbon fiber's high stiffness and strength are utilized in bicycles, golf clubs, and tennis rackets.

* Robotics: Its stiffness and lightweight properties are crucial for precision and control in robotic applications.

By understanding the unique performance characteristics of carbon fiber, engineers and manufacturers can leverage its properties to create superior and high-performing products across various sectors. Supreem Carbon is committed to providing top-quality carbon fiber parts that meet the demands of today's high-performance applications.

Rev Up Your Ride: Supreem Carbon - China's Finest Custom Motorcycle Carbon Fiber Parts

What does carbon fiber do for a motorcycle?

Supreem Carbon new arrivals released!

Newest Acura NSX Carbon Fiber Hood Vent released!

Is carbon fiber good for cars?

How to Make Carbon Fiber Car Parts?

For Products

Supreem Carbon parts produce by 100% carbon?

Yes,all products are made from full carbon with dry carbon.

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

For After-sales Service

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

Ducati Panigale V4 Carbon Fiber Side Fairings

Custom Made BMW S1000RR Performance Carbon Fiber Heel Plates

These carbon fiber parts are 100% handmade and formed through an autoclave process. It can not only reduce the weight of the vehicle body but also improve the overall performance of the motorcycle. Give you a different visual experience.

Yamaha R1 R1M Carbon Fiber Front Fairing

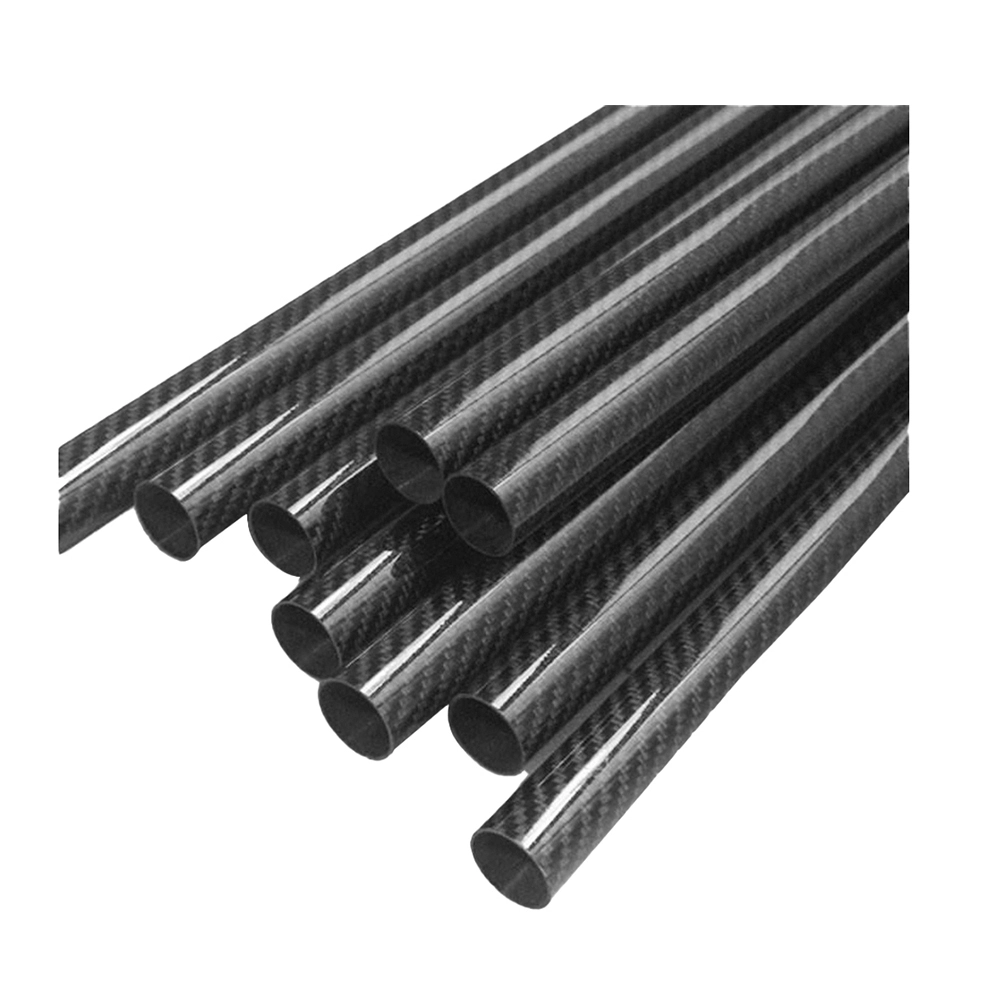

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram