Is carbon fiber good for drones? | Supreem Carbon Guide

Is Carbon Fiber Good for Drones?

The use of carbon fiber in drone manufacturing presents an effective solution to several industry challenges. By addressing concerns about weight, durability, and performance, carbon fiber stands out as an ideal choice for drone construction. Let's delve into why carbon fiber is advantageous for drones.

Benefits of Carbon Fiber for Drones

Lightweight Yet Strong

One of the primary reasons carbon fiber is popular in drone production is its lightweight nature combined with superior strength. Traditional materials often compromise between weight and durability, but carbon fiber offers an exceptional balance. This characteristic is key for drones, where reduced weight can enhance flight time and efficiency while maintaining robustness.

Enhanced Durability

Professionals in the field recognize the importance of durable components in minimizing maintenance costs and ensuring the longevity of drones. Carbon fiber's resistance to environmental conditions—such as temperature fluctuations and moisture—makes it a reliable material. Its long-lasting durability reduces the frequency of repairs and replacements, making it an economically sound choice.

Performance Improvement

Increased Maneuverability

Drones made with carbon fiber parts benefit from improved maneuverability. The material's rigidity ensures that the drone can maintain stability during flight, providing precision and control that professionals demand. This maneuverability is vital for applications requiring intricate aerial movements, such as in filmography or agriculture.

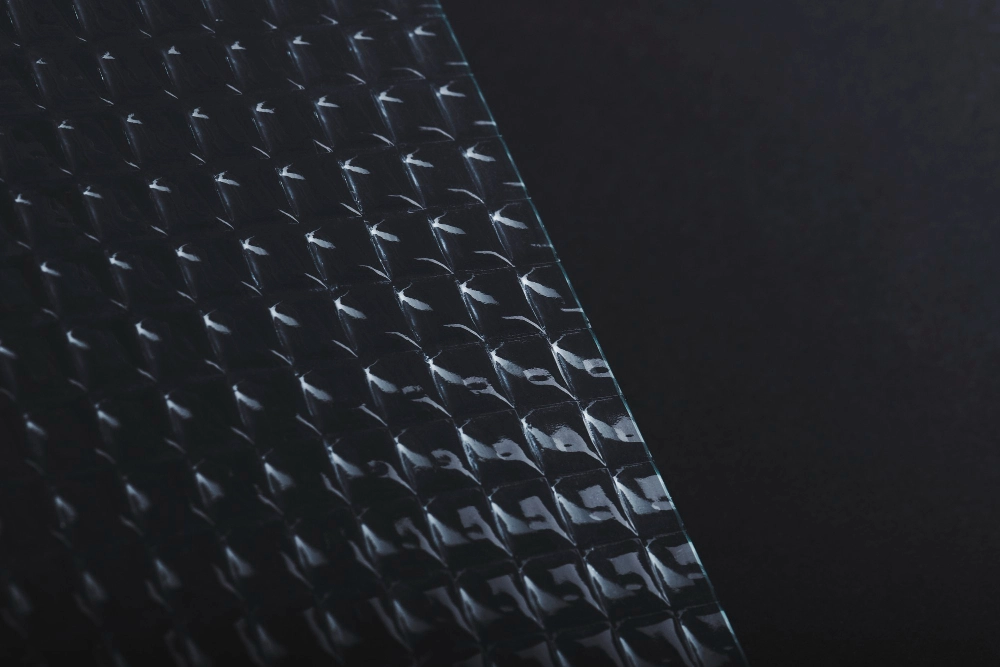

Aesthetic and Functional Design

Carbon fiber allows for complex, sleek designs that enhance both the aesthetics and functionality of drones. Its versatility enables manufacturers to create parts tailored to specific drone models, optimizing aerodynamics and efficiency. Moreover, its distinct appearance provides a modern and professional look, appealing to discerning customers.

Economical Considerations

Cost Efficiency

While the initial investment in carbon fiber components might be higher than traditional materials, its durability and performance generate long-term savings. Reduced maintenance and extended lifespan make carbon fiber a cost-effective solution for both hobbyists and commercial operators.

Sustainability

As sustainability becomes increasingly critical in manufacturing, carbon fiber's role in producing lighter vehicles points towards reduced emissions and energy consumption. By choosing carbon fiber, the drone industry can contribute to broader environmental goals.

Conclusion: An Ideal Material

In conclusion, carbon fiber is highly suitable for drone applications. It addresses key challenges of weight, durability, and performance, offering solutions that propel the industry forward. At Supreem Carbon, we provide expertise and resources to help professionals harness the full potential of carbon fiber, pushing the boundaries of innovation in the drone market.

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

Latest Developments in the Application of Carbon Fiber Materials in the Automotive and Motorcycle Fields

Supreem Carbon: Asya'nın En İyi Profesyonel Motosiklet Karbon Fiber Üretici Markası

Application Advantages of Carbon Fiber in Automobile Chassis Brackets

How Long Do Carbon Fiber Parts Last? | Supreem Carbon

Carbon Fiber Helmet produced by Supreem Carbon.

For Products

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

For After-sales Service

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

Kawasaki Z650 Carbon Fiber Tank Side Panels

Honda CBR1000RR-R Carbon Fiber Belly Pan Lower Side Fairings

Suzuki GSX-R1000 Carbon Fiber Chain Guard

Kawasaki ZX10R Carbon Fiber Rear Tail Panel

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram