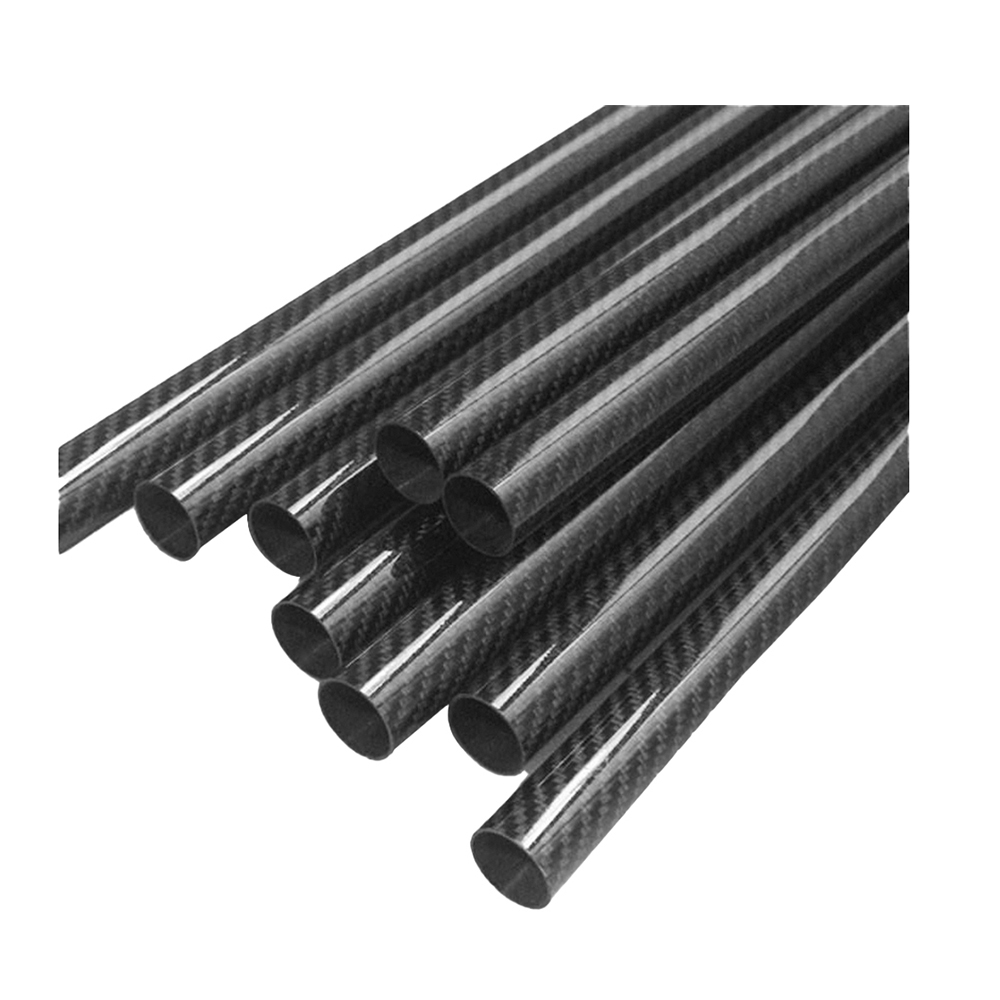

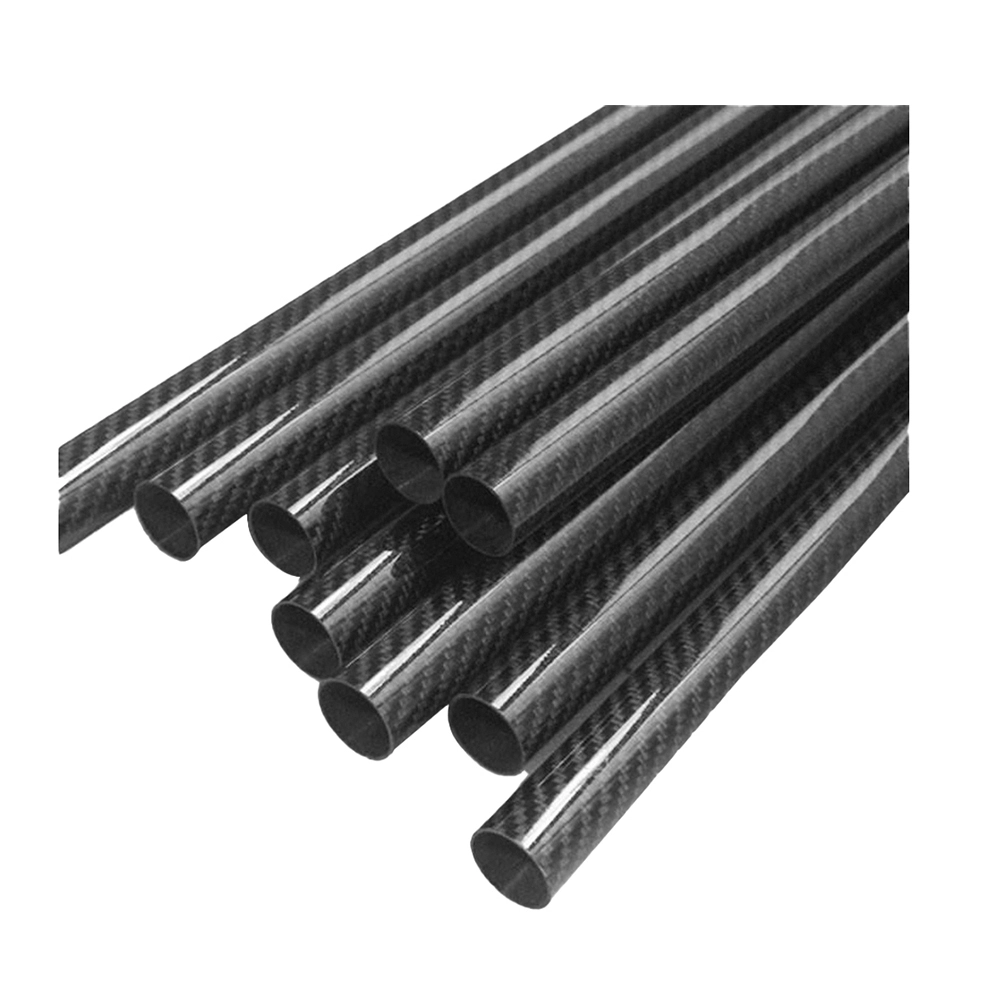

Supreem Carbon — Trusted Carbon Fiber Tube Supplier for Automotive & Motorcycle Parts

Supreem Carbon — Your Reliable carbon fiber tube supplier

Company Overview

Supreem Carbon, founded in 2017, is a customized manufacturer of carbon fiber parts for automobiles and motorcycles. With a 4,500 m² facility, 45 skilled technicians, and an annual output value near $4M, we focus on R&D, design, production, and sales to provide durable, lightweight, and precision-engineered carbon fiber tubes and components. As a committed carbon fiber tube supplier, we deliver both standard and custom solutions to global OEMs and aftermarket customers.

Precision Manufacturing & Capacity

Our factory leverages advanced composite processes and strict quality controls to produce consistent, high-strength carbon fiber tubes. We manufacture more than 1,000 product types—including over 500 customized carbon fiber parts—ensuring rapid prototyping, scalable production, and tight tolerances. If you need a carbon fiber tube supplier who can handle small-batch prototypes and large-volume runs, Supreem Carbon meets both demands.

Custom Solutions for Automotive & Motorcycle Use

We specialize in custom carbon fiber accessories, luggage, and sports equipment with tailored layups, finishes, and fittings. Whether you require aerodynamic tubing for motorcycles, structural tubes for vehicle frames, or custom-diameter carbon fiber tubes for specialty applications, our design team collaborates closely with clients to convert concepts into production-ready parts.

R&D, Quality & Reliability

R&D is central to our offering—material selection, resin systems, and fiber orientation are optimized for each application. Supreem Carbon applies rigorous testing and inspection protocols to ensure product longevity and performance. As a trusted carbon fiber tube supplier, we prioritize traceability, consistent mechanical properties, and excellent surface finish for both functional and aesthetic parts.

Why Choose Supreem Carbon

Choosing Supreem Carbon means partnering with a results-driven manufacturer that combines technical expertise, comprehensive product lines, and customer-focused service. Fast lead times, competitive pricing, and the ability to customize over 500 unique carbon fiber parts make us an ideal carbon fiber tube supplier for OEMs, tuners, and designers. Visit https://www.supreemcarbon.com/ to request a quote or discuss custom requirements.

carbon fiber tube supplier Display

- Strong Production Capacity

We have a substantial daily production capacity to meet the demands of bulk orders, ensuring a smooth supply chain for you. Average monthly production capacity is nearly 3,500 pieces.

- Project consultation

Our designers will provide customers with project feasibility analysis and quotations based on the ideas and design concepts or drawings provided by customers.

- Professional development suggestions

Our engineers will provide customers with professional development suggestions based on different products and different uses.

- Rich R&D Experience

Our R&D team members are all professional and technical personnel who have been working in the carbon fiber industry for more than 10 years. We can understand customer needs as soon as possible and provide development technical support.

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

High-Performance Carbon Fiber Rear Undertail for BMW S1000R

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Carbon Fiber Rear Seat Panel for BMW S1000R & M1000RR – Lightweight Performance

Yamaha R1/R1M Carbon Fiber Rear Fender Hugger Mudguard

Yamaha R1/R1M Carbon Fiber Rear Fender Hugger Mudguard

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover

Kawasaki ZX10R Carbon Fiber Upper Tank Airbox Cover2025 Ducati Panigale V4/V4S Carbon Fiber Body Kit released by Supreem Carbon.

Redefining Lightweight Performance and Aesthetic Precision in Motorcycle Design

Supreem Carbon Cross-Country Mountain Bike Seat: The Ultimate Lightweight Carbon Fiber Upgrade

Discover ultimate performance with Supreem Carbon's Carbon Fiber Cross Country Mountain Bike Seat. Expertly crafted for avid cyclists, this lightweight seat is designed to enhance your biking experience with superior comfort and durability. Made from premium carbon fiber parts, it offers exceptional strength while minimizing weight. Perfect for cross-country adventures, this seat embodies quality and innovation that Supreem Carbon is renowned for. Elevate your ride and explore the world with confidence. Optimize your biking performance with our top-tier carbon fiber seat today.

Xiaomi SU7 Carbon Fiber Aerodynamic Body Kit – Supreem Carbon Testing Feedback

In this article, we share Supreem Carbon’s in-depth testing feedback on the Xiaomi SU7 carbon fiber aerodynamic body kit. From the front splitter and side skirts to the rear wing and aerodynamic fender covers, we evaluate how the carbon fiber components perform in terms of weight reduction, structural integrity, and visual appeal. Learn how these upgrades affect the vehicle’s performance, safety, and aesthetics.

Analysis of Delamination Problems in Carbon Fiber Products and How to Avoid it

Discover insights into delamination in carbon fiber products. Our analysis explores common causes of carbon fiber delamination and effective strategies to prevent it, ensuring the longevity and reliability of your products. Enhance your understanding of delamination challenges and solutions by reading our comprehensive guide tailored for industry professionals.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram