Carbon Fiber Composites: Applications, Benefits, and Industry Trends

Gain an in-depth understanding of carbon fiber composites, their transformative impact on automotive, aerospace, and renewable energy, and the latest industry insights shaping the future of high-performance materials.

- History of Carbon Fiber Composites

- Major Applications of Carbon Fiber Composites Across Industries

- Carbon Fiber Composites – Advantages and Disadvantages

- Automotive Innovation: How Carbon Fiber Is Transforming EVs and Performance Cars

- Aerospace Applications: Carbon Fiber in Modern Aircraft and Drones

- Renewable Energy Trends: Carbon Fiber Composites in Wind Turbine Blades

- Sustainability & Recycling: The Green Future of Carbon Fiber Composites

- 8 Secrets About Carbon Fiber Composites

- Carbon Fiber Composites Industry Trends and Forecasts (2025–2035)

- Conclusion

The contemporary engineering and production world is increasingly characterized by the need for materials that are strong, lightweight, and versatile. One of the most revolutionary materials in this regard is carbon fiber composite. These materials allow engineers to push the boundaries of design and performance in the aerospace, automotive, renewable energy, and consumer products industries. Their rigidity, durability, and light weight enable the development of innovative solutions that were previously impossible with conventional metals or plastics.

This detailed guide covers the definition, history, key uses, pros and cons, and industry trends that will determine the future of carbon fiber composites.

History of Carbon Fiber Composites

To realize the potential of carbon fiber composites, it is important to understand their history. Carbon fibers were initially invented in the late 19th and early 20th centuries and were first used in applications requiring high strength, such as light bulb filaments and early military equipment. Modern carbon fiber, as an element of composite materials, originated in the 1960s with the creation of PAN- and pitch-based fibers.

Due to their impressive strength-to-weight ratio, the first carbon fiber composites were used in aerospace and defense. NASA and other aerospace organizations were the first to use these materials in spacecraft structures, satellites, and high-performance aircraft components. Over the decades, the manufacturing of carbon fiber composites has been enhanced with prepreg layup, autoclave curing, and automated fiber placement to improve quality, consistency, and scalability.

The history of carbon fiber composites shows a gradual shift from niche aerospace products to a wide variety of industrial, automotive, and consumer products, which paves the way for today's innovations.

Major Applications of Carbon Fiber Composites Across Industries

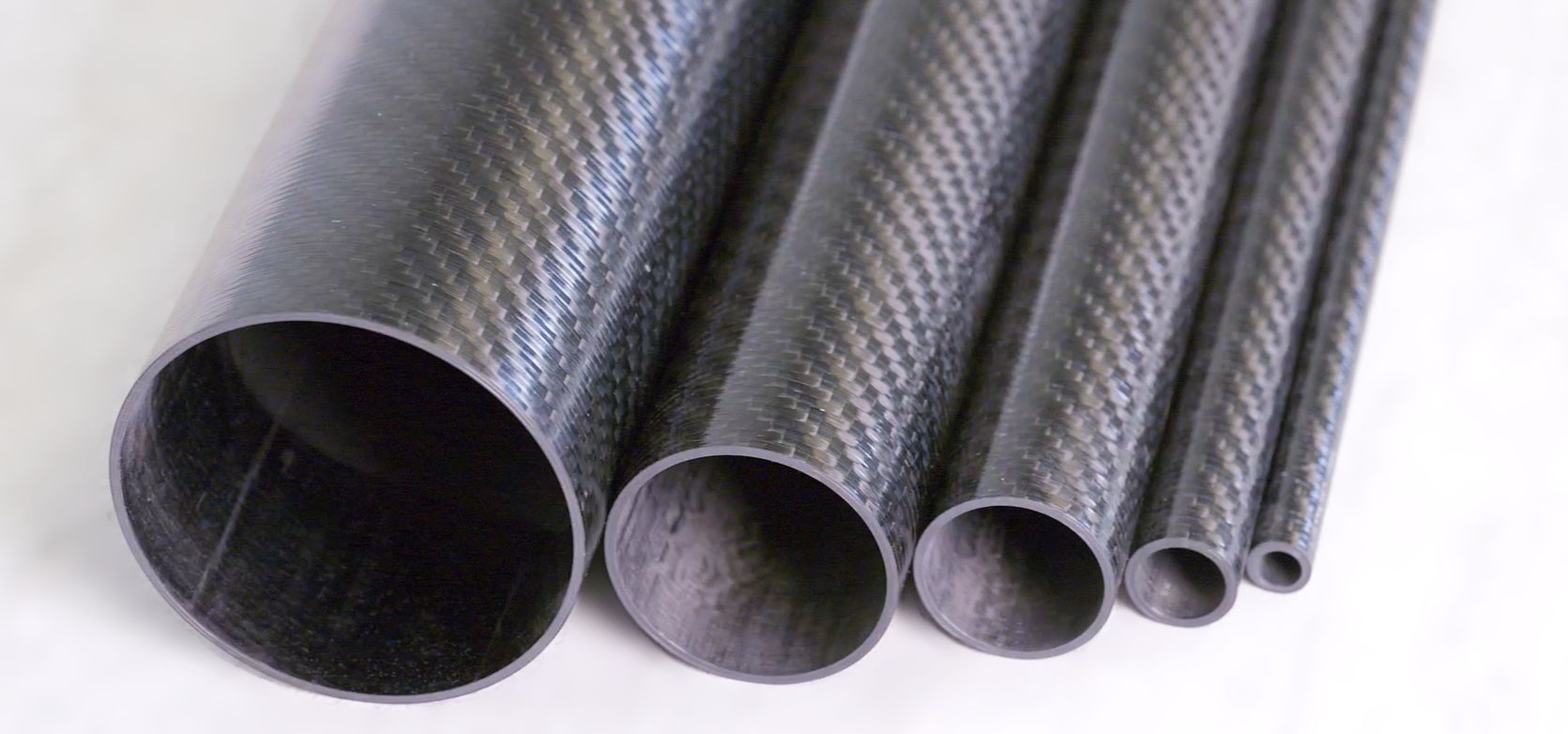

The versatility of carbon fiber composites allows them to be applied in a wide array of industries.

- Automotive: Carbon fiber composite materials are extensively used for performance car panels, chassis reinforcement, interior trim, and battery enclosures in electric vehicles (EVs). Reduced weight translates to improved fuel efficiency, acceleration, and handling.

- Aerospace: Aerospace carbon fiber composites are critical for fuselage panels, wing spars, and UAV structures due to their strength-to-weight ratio, corrosion resistance, and fatigue durability.

- Sporting Goods: High-performance bicycles, tennis rackets, and ski poles leverage carbon fiber composites to optimize stiffness, responsiveness, and durability.

- Industrial & Construction: Carbon fiber composite sheets and plates are used in bridge reinforcement, structural retrofits, and industrial machinery components, balancing structural integrity with reduced weight.

- Marine: Carbon fiber composites contribute to lightweight, strong hulls and deck structures in yachts, racing boats, and submarines.

Manufacturers can meet specific performance requirements for mass production or highly customized projects by tailoring weave patterns, resin types, and fiber orientations.

Carbon Fiber Composites – Advantages and Disadvantages

Understanding the strengths and limitations of carbon fiber composites is crucial for informed application.

Advantages:

- High Strength-to-Weight Ratio: Carbon fibers provide tensile strength far superior to steel at a fraction of the weight.

- Durability: The resin matrix protects fibers, ensuring resistance to fatigue, stress, and environmental degradation.

- Design Flexibility: Can be molded into complex geometries without compromising mechanical properties.

- Corrosion Resistance: Does not rust or degrade when exposed to moisture or chemicals.

- Thermal Stability: Maintains performance over wide temperature ranges.

Disadvantages:

- High Material Cost: Production and prepreg materials are expensive compared to metals.

- Manufacturing Complexity: Requires specialized processes and equipment for consistent results.

- Brittleness: Carbon fiber composites can crack under high impact forces.

- Limited Repair Options: Damaged components often require full replacement rather than simple repair.

Despite these limitations, the advantages make carbon fiber composite materials indispensable in high-performance applications.

Automotive Innovation: How Carbon Fiber Is Transforming EVs and Performance Cars

Car manufacturers are adopting carbon fiber composite materials to improve vehicle efficiency and performance. Carbon fiber is used in high-end, high-performance cars:

- Monocoque chassis and crash structures

- lightweight body panels and aerodynamic parts

- Interior decorative elements to beautify the interior

- Electric vehicles, where it improves battery casings and enhances range

Electric vehicle brands are adopting carbon fiber composites because they can lower a vehicle's mass, thus making it more energy efficient. The material's stiffness and impact resistance are advantageous for performance-oriented manufacturers because they can handle it better, brake, and accelerate. Carbon fiber composite manufacturing is also used by original equipment manufacturers (OEMs) and aftermarket suppliers to provide custom panels, fenders, spoilers, and aerodynamic kits that combine beauty and functionality.

Carbon fiber allows automotive brands to push the boundaries of engineering and provide consumers with lighter, safer, and more aesthetically pleasing cars.

Aerospace Applications: Carbon Fiber in Modern Aircraft and Drones

Carbon fiber composites have become essential in the aerospace industry. Aircraft manufacturers use these composites for:

- Wing spars and fuselage panels

- Drone frames and unmanned aerial vehicle (UAV) structures

- Aerospace interior parts and rotor blades

Their lightweight characteristics combined with high mechanical strength decrease fuel consumption and increase aircraft lifespan. High-technology carbon fiber composite production techniques, including automated fiber placement (AFP) and prepreg layup, ensure consistency and minimize flaws in critical components. Furthermore, carbon fiber composites are more fatigue-resistant and require less maintenance than aluminum and conventional alloys. Thus, they are the foundation of modern aerospace engineering.

Renewable Energy Trends: Carbon Fiber Composites in Wind Turbine Blades

The renewable energy sector has embraced carbon fiber composites for high-performance wind turbine blades. The material’s light weight allows longer blades without additional structural weight, increasing energy capture and efficiency.

- Carbon fiber composites reduce fatigue damage in long-span rotor blades.

- They enable larger turbine designs with improved aerodynamics.

- Manufacturers are integrating advanced resin systems to improve weather resistance and blade lifespan.

As governments and companies prioritize expanding renewable energy, carbon fiber composite materials are expected to continue growing in large-scale energy applications. These applications include solar support structures and lightweight components for offshore platforms.

Sustainability & Recycling: The Green Future of Carbon Fiber Composites

While carbon fiber composites offer unmatched performance, sustainability is becoming increasingly important. Modern efforts focus on:

- Recycling and reclaiming carbon fibers from end-of-life components

- Developing bio-based resins and eco-friendly curing processes

- Optimizing manufacturing to reduce energy consumption and waste

These initiatives ensure that carbon fiber composites are compatible with environmental regulations and support the principles of a circular economy. Companies that invest in sustainable manufacturing gain a competitive edge while meeting growing consumer and regulatory demands.

8 Secrets About Carbon Fiber Composites

- Carbon fiber composites can be tailored for stiffness, strength, and weight.

- Prepreg materials provide precise resin content for consistent performance.

- Automated fiber placement enables complex shapes with minimal defects.

- Carbon fiber composites are increasingly replacing metals in high-end EVs.

- Aerospace carbon fiber composites are used in fuselage, wings, and drone structures.

- Hybrid composites combine carbon fiber with metals or thermoplastics for enhanced properties.

- Advanced curing techniques improve fatigue life and surface finish.

- Carbon fiber composites are recyclable with emerging technologies.

Carbon Fiber Composites Industry Trends and Forecasts (2025–2035)

The carbon fiber composites industry is projected to grow at a robust rate due to demand from automotive, aerospace, and renewable energy sectors. Key trends include:

- Automation and Advanced Manufacturing: Increasing adoption of AFP, RTM (Resin Transfer Molding), and additive manufacturing for high-volume production

- Custom and Hybrid Composites: Combining carbon fiber with thermoplastics, aluminum, and other reinforcements for improved performance

- Market Expansion: Broader use in mass-market EVs, consumer electronics, and sporting goods

- Sustainability & Circular Economy: Recycling technologies, bio-based resins, and lifecycle assessment are gaining focus

It is projected that by 2035 carbon fiber composites will be a common engineering material and will enable the production of the next generation of lightweight, high-performance, and sustainable products in a variety of industries.

Conclusion

Carbon fiber composite is no longer a niche material. It is revolutionizing industries thanks to its unmatched strength, lightweight characteristics, and versatility. These materials are used to innovate and improve efficiency in the automotive and aerospace industries, promote sustainability in renewable energy use, and provide high-performance solutions for consumer products. The popularity of carbon fiber composites underscores their importance in determining the future of engineering and design.

Supreem Carbon: Asya'nın En İyi Profesyonel Motosiklet Karbon Fiber Üretici Markası

100% Carbon fiber dash panel and window door trims set for NSX

Carbon Fiber Helmet produced by Supreem Carbon.

Kawasaki ZX10R Carbon Fiber New Pattern Look.

Carbon Fibers: What Are They and Why Are They Everywhere? (Production, Properties, and Uses Explained)

Rev Up Your Ride: Supreem Carbon - China's Finest Custom Motorcycle Carbon Fiber Parts

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

For Customized Service

What custom customer need to prepare?

1. Send Your Design/Idea/3D drawing.

2. Supplier Quotation Confirmation.

3. Firts Sample Feedback.

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

For Facotry

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

Kawasaki ZX10R Carbon Fiber Rear Tail Panel

Ducati Monster 937 Carbon Fiber Rear Fender

Aucra NSX Carbon Fiber Nose Beak Replacement

Give your 2017+ NSX front a more unique look with our direct replacement carbon fiber Nose Beak. Each piece is carefully hand-crafted for a perfect fitment in any NSX.

Kawasaki H2/H2R Carbon Fiber Side Fairing

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram