why carbon fiber is expensive for aerospace | Insights by Supreem Carbon

What Are the Primary Factors Contributing to the High Cost of Carbon Fiber in Aerospace?

The elevated cost of carbon fiber in aerospace applications can be attributed to several key factors:

Raw Material Expenses: The production of carbon fiber predominantly utilizes polyacrylonitrile (PAN) as the precursor material. PAN is a synthetic polymer that requires an energy-intensive process for its production, involving specific chemical reactions and precise control over temperature and pressure. This complexity and energy consumption significantly increase the cost of the raw material.

Complex Manufacturing Processes: The transformation of PAN into carbon fiber involves multiple intricate stages, including stabilization, carbonization, and surface treatment. Each of these steps demands specialized equipment and meticulous control to ensure the desired material properties. The need for high precision and the energy-intensive nature of these processes contribute to the overall expense.

Specialized Equipment and Skilled Labor: Manufacturing carbon fiber components requires specialized equipment such as autoclaves, curing ovens, and precision molding tools. Additionally, the process demands skilled technicians to operate this equipment and to perform tasks like layup, inspection, and quality control. The combination of expensive machinery and the necessity for highly trained personnel adds to the production costs.

Limited Economies of Scale: Unlike metals such as steel and aluminum, which benefit from large-scale production and established supply chains, carbon fiber production remains relatively niche. The lower volume of production means that manufacturers cannot achieve the same economies of scale, resulting in higher per-unit costs.

Research and Development Investments: Continuous advancements in carbon fiber technology require substantial investment in research and development. These costs are often passed on to consumers, contributing to the higher price point of carbon fiber products.

How Do These Factors Impact the Aerospace Industry?

The high cost of carbon fiber presents both challenges and opportunities within the aerospace sector:

Performance Benefits: Despite the expense, carbon fiber offers significant advantages, including a high strength-to-weight ratio, corrosion resistance, and improved fuel efficiency. These benefits make it a valuable material for aerospace applications, leading to its continued adoption despite the higher costs.

Cost-Benefit Analysis: Aerospace manufacturers must carefully weigh the initial higher costs of carbon fiber against the long-term performance and operational savings. In many cases, the enhanced performance and reduced maintenance costs justify the investment.

What Are the Future Prospects for Carbon Fiber Costs in Aerospace?

The future of carbon fiber costs in aerospace is influenced by several factors:

Technological Advancements: Ongoing research aims to develop more efficient manufacturing processes and alternative materials that could reduce costs. However, challenges such as the need for precise control over production parameters and the high energy consumption of current methods mean that significant cost reductions may take time to materialize.

Market Demand and Supply Dynamics: As demand for carbon fiber in aerospace applications grows, economies of scale may help lower costs. However, the specialized nature of aerospace components and the need for high-quality materials may continue to keep prices elevated.

Conclusion: The Advantages of Choosing Supreem Carbon

Supreem Carbon offers a comprehensive solution for aerospace manufacturers seeking high-quality carbon fiber components. With a focus on precision manufacturing, advanced material selection, and a commitment to innovation, Supreem Carbon ensures that clients receive products that deliver optimal performance and value. By partnering with Supreem Carbon, aerospace companies can leverage the benefits of carbon fiber while effectively managing costs.

References:

IMPACT MATERIALS — "Why Carbon Fiber Is So Expensive" — Published: 1.6 years ago

DragonPlate — "Why Are Carbon Fiber Parts So Expensive?" — Published: September 9, 2020

Managing Composites — "Why is carbon fiber so expensive?" — Published: 2 weeks ago

JCC Carbon Fiber Fabrication — "Carbon Fiber High Cost: What Makes it So Expensive?" — Published: 9 months ago

CarbonXtreme — "The Real Reasons Carbon Fiber Remains Expensive in 2025" — Published: yesterday

Ultimate Guide to Custom Carbon Fiber Car Parts (Performance, Process & Buying Tips)

Supreem Carbon: Asya'nın En İyi Profesyonel Motosiklet Karbon Fiber Üretici Markası

Analysis of Delamination Problems in Carbon Fiber Products and How to Avoid it

New arrivals- BMW CSL style carbon fiber front grille released by Supreem carbon!!

Application of 3D Printing in Carbon Fiber Accessories

What Are the Most Common Uses of Carbon Fiber in 2025?

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

For Facotry

Supreem carbon main competitive advantages.

Rich experience

Over 10 years production experience in carbon fiber industry, providing customers with high quality carbon products.

Excellent service

From new project development to customer finished product delivery, we provide customers with full tracking and timely feedback on project progress.

High-Quality Products

Our carbon fiber products undergo rigorous quality control to ensure customers achieve the high quality and cost-effective product.

For After-sales Service

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

Ducati Panigale V4 Carbon Fiber Side Fairings

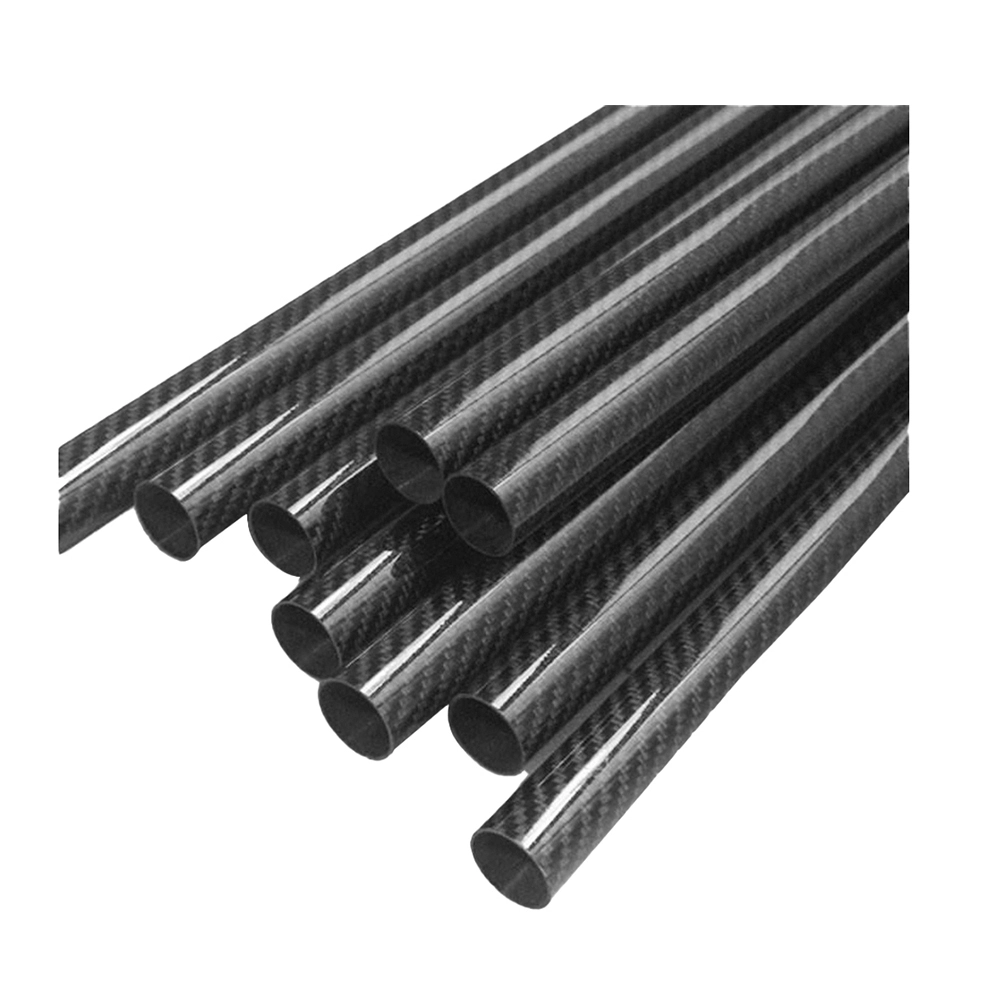

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber finds numerous applications in tube and sheet forms due to its exceptional properties, including its high strength, lightweight nature, and versatility.

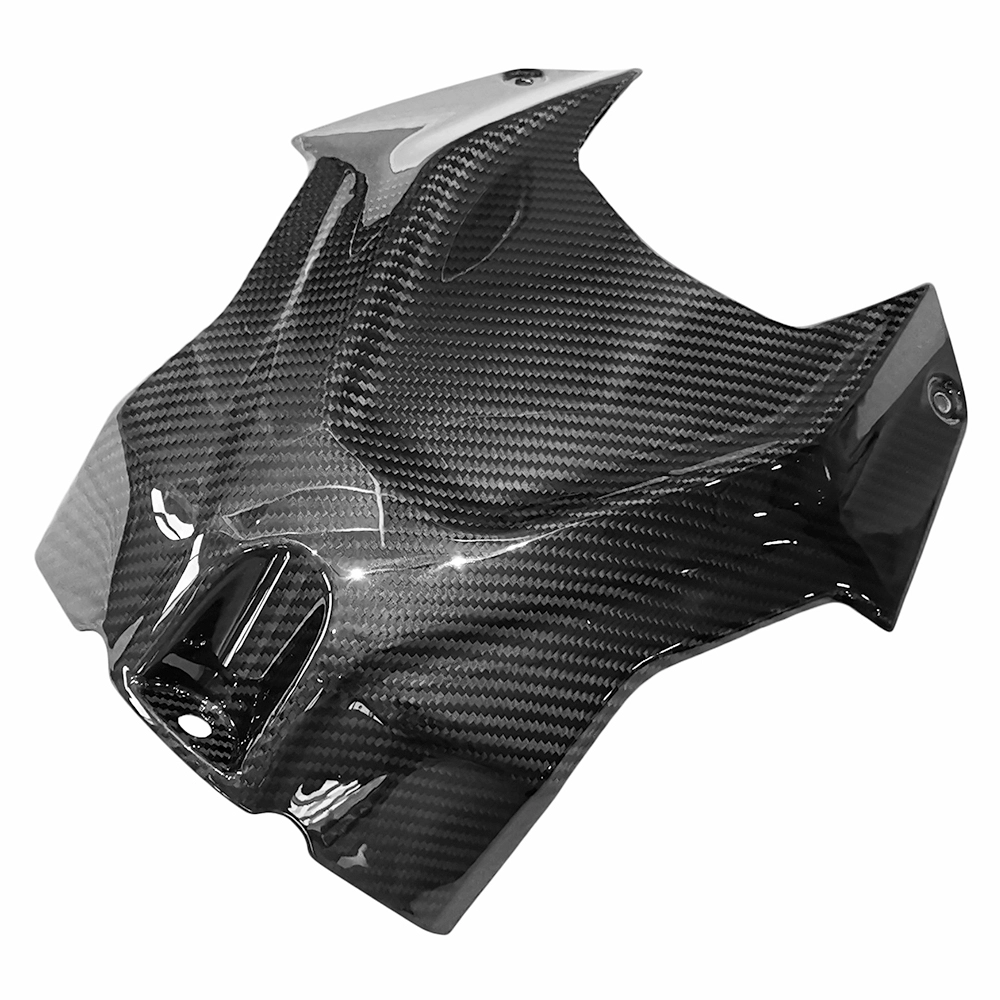

BMW S1000RR S1000R Carbon Fiber Tank Airbox Cover

Chevrolet Corvette C8 Carbon Fiber Paddle Shifters

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram