what are the best applications of carbon-fiber composites in defense | Insights by Supreem Carbon

Carbon-fiber composites have become integral to modern defense technologies, offering a unique combination of strength, lightweight properties, and durability. Their applications span various defense sectors, significantly enhancing performance and operational efficiency.

Lightweight Military Vehicles and Components

In the defense sector, carbon-fiber composites are utilized to manufacture lightweight military vehicles and components, including armor and ballistic protection systems. These materials provide enhanced strength-to-weight ratios, improving mobility and fuel efficiency while maintaining high levels of protection.

Advanced Aerospace Structures

The aerospace industry employs carbon-fiber composites to construct aircraft structures, such as fuselages, wings, and tail sections. These composites reduce weight, leading to improved fuel efficiency and payload capacity. Additionally, they offer superior resistance to corrosion, extending the service life of aerospace components.

Enhanced Ballistic Protection

Carbon-fiber composites are integral in developing advanced ballistic protection systems, including helmets and body armor. Their lightweight nature reduces fatigue for personnel, while their strength provides effective defense against ballistic threats.

Improved Durability and Maintenance

The exceptional durability of carbon-fiber composites ensures that military assets can withstand harsh environments, reducing maintenance costs and enhancing operational readiness. Their resistance to wear and tear contributes to longer service life for defense equipment.

Integration in Unmanned Aerial Vehicles (UAVs)

UAVs benefit from carbon-fiber composites through enhanced performance and durability. The lightweight nature of these materials allows for longer flight times and increased payload capacity, while their strength ensures structural integrity during operations.

Cost-Effectiveness in Production

Utilizing carbon-fiber composites in defense manufacturing can lead to cost savings. Their ability to be molded into complex shapes reduces the number of parts and assembly time, streamlining production processes.

Conclusion

Carbon-fiber composites are transforming the defense industry by providing materials that are both strong and lightweight, leading to enhanced performance, durability, and cost-effectiveness. Their diverse applications across military vehicles, aerospace structures, and protective gear underscore their critical role in modern defense technologies.

About Supreem Carbon

Supreem Carbon specializes in advanced carbon-fiber composite solutions tailored for the defense sector. Our products are engineered to meet stringent military standards, offering superior performance and reliability. With a commitment to innovation and excellence, Supreem Carbon delivers cutting-edge composite solutions that provide exceptional value and strategic advantages in the field.

SEO Information

- Meta Title: Best Applications of Carbon-Fiber Composites in Defense

- Meta Description: Explore how carbon-fiber composites enhance defense technologies, offering strength, lightweight properties, and durability across various applications.

- Keywords: carbon-fiber composites, defense applications, military vehicles, aerospace structures, ballistic protection, UAVs, Supreem Carbon

- URL Alias: best-carbon-fiber-composites-defense

Data Sources

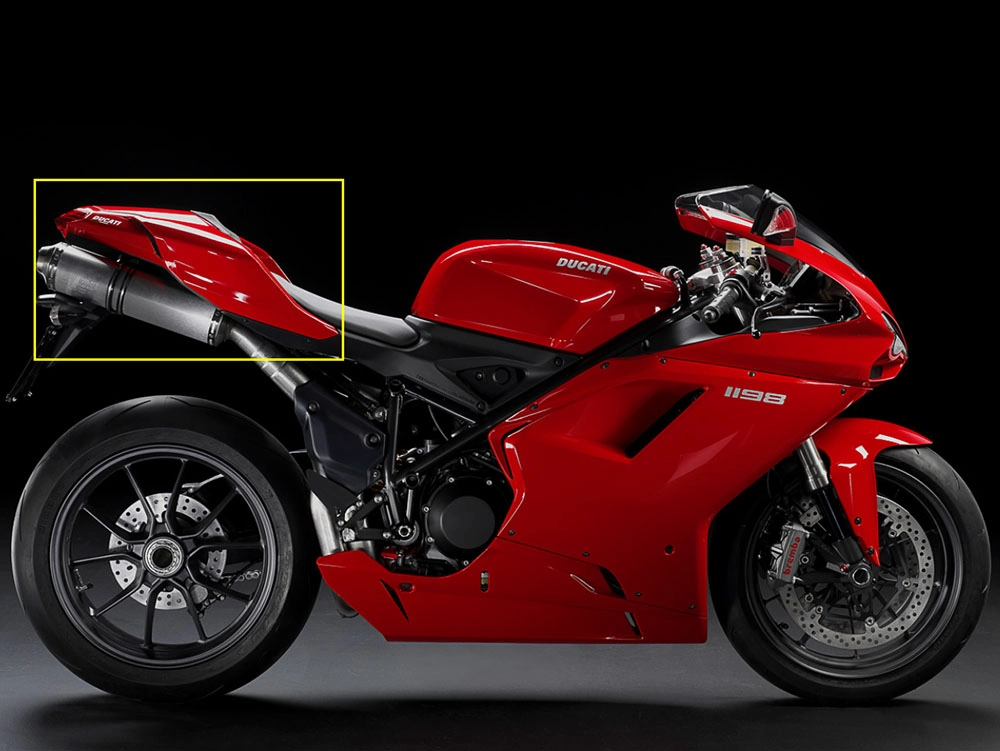

Fabricante de fibra de carbono para motocicletas de alta calidad de China

Prepreg Carbon Fiber: The Definitive Guide to Advanced Composite Performance

The Ultimate Guide to Carbon Fiber in Aerospace Applications

Supreem Carbon Auto parts new arrivals!

Carbon Fiber Hoods: Your Ultimate Guide to Performance, Aesthetics, and Value

100% Carbon fiber dash panel and window door trims set new arrivals!

For After-sales Service

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

Custom Made BMW S1000RR Performance Carbon Fiber Heel Plates

These carbon fiber parts are 100% handmade and formed through an autoclave process. It can not only reduce the weight of the vehicle body but also improve the overall performance of the motorcycle. Give you a different visual experience.

Yamaha R1/R1M Carbon Fiber Rear Fender Hugger Mudguard

Ducati Desert X Carbon Fiber Sprocket Cover

Ducati Monster 937 Carbon Fiber Sprocket Cover

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram