how to form carbon fiber parts | Supreem Carbon Expert Guide

- Comprehensive Guide to Carbon Fiber Part Manufacturing Processes for Procurement

- What are the Primary Methods for Forming Carbon Fiber Parts?

- Key Factors When Choosing a Carbon Fiber Manufacturing Process

- Typical Costs Associated with Manufacturing Carbon Fiber Parts

- Common Challenges in Carbon Fiber Part Production and Solutions

- Essential Quality Control Measures for Carbon Fiber Components

Comprehensive Guide to Carbon Fiber Part Manufacturing Processes for Procurement

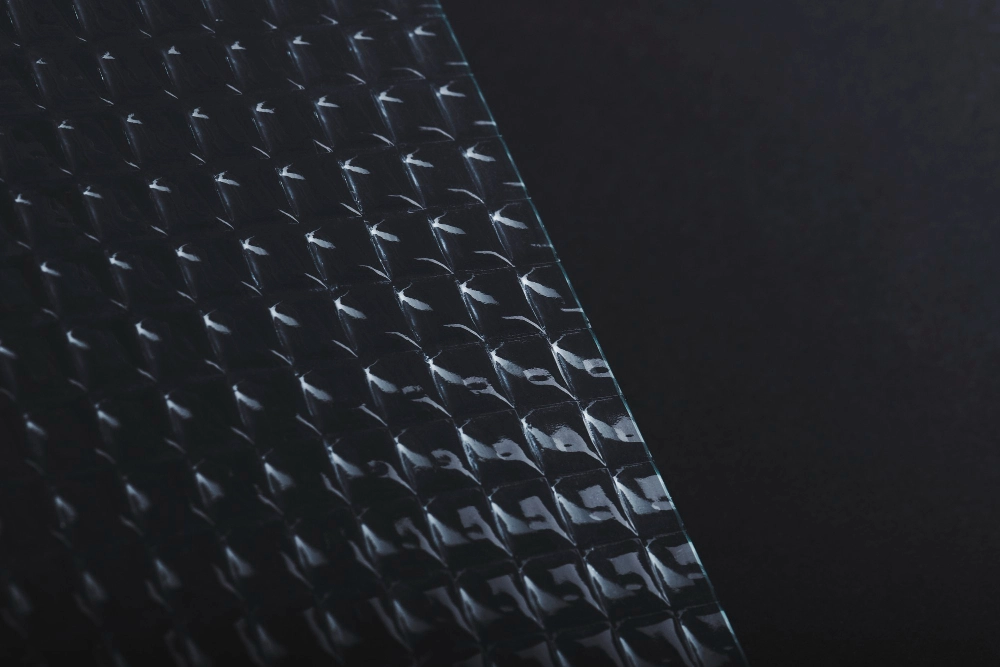

Carbon fiber composites are increasingly vital across industries, from aerospace and automotive to sports equipment and renewable energy, thanks to their exceptional strength-to-weight ratio, stiffness, and corrosion resistance. For industry professionals involved in procurement, understanding the various manufacturing processes is crucial for making informed decisions, optimizing costs, and ensuring quality. This guide delves into the core methods of forming carbon fiber parts, addresses common challenges, and outlines essential quality control measures, providing the knowledge needed to navigate procurement effectively.

What are the Primary Methods for Forming Carbon Fiber Parts?

The choice of manufacturing process significantly impacts a part's mechanical properties, cost, and production scalability. Key methods include:

- Wet Lay-up: Resin is applied to dry carbon fiber fabric directly in the mold. It's labor-intensive, offers good flexibility for complex shapes, and has low tooling costs, but part consistency and mechanical properties can vary. Typically used for prototypes or low-volume production.

- Prepreg Lay-up (and Autoclave Curing): Pre-impregnated (prepreg) carbon fiber sheets, already embedded with a precise amount of resin, are laid up in a mold. This method offers superior fiber-to-resin ratio control and higher mechanical properties. Curing often occurs in an autoclave under heat and pressure, resulting in very low void content (often <1%) and excellent structural integrity. Ideal for high-performance applications like aerospace, though tooling and operational costs are high.

- Resin Transfer Molding (RTM) / Vacuum Assisted Resin Transfer Molding (VARTM): Dry carbon fiber preforms are placed into a closed mold, and resin is injected (RTM) or drawn in by vacuum (VARTM). These processes offer good surface finish on both sides, repeatable part quality, and are suitable for medium-to-high volume production of moderately complex parts. VARTM is more flexible in mold design and lower cost than RTM.

- Compression Molding: Pre-formed carbon fiber sheets (often chopped fibers or prepreg) are placed in a heated mold, and pressure is applied to cure the resin. This process is highly efficient for high-volume production of complex, intricate parts with excellent surface finish and dimensional accuracy. Tooling costs are high, but cycle times are short.

- Filament Winding: Continuous carbon fibers, saturated with resin, are wound over a rotating mandrel. This method is ideal for producing hollow, symmetrical parts like pipes, tanks, or pressure vessels, offering high strength in specific directions. It's cost-effective for high volumes of cylindrical or conical shapes.

- Pultrusion: Carbon fibers are pulled through a resin bath and then through a heated die that shapes and cures the composite. This continuous process is highly efficient for producing constant cross-section profiles (e.g., rods, tubes, I-beams) with excellent unidirectional properties. It's very cost-effective for high-volume linear parts.

- Additive Manufacturing (3D Printing): Emerging technologies like FDM with continuous fiber reinforcement or SLA/DLP with chopped carbon fibers allow for rapid prototyping and complex geometries. While mechanical properties are improving, they generally do not yet match those of traditional manufacturing methods for structural applications.

Key Factors When Choosing a Carbon Fiber Manufacturing Process

Selecting the optimal process involves balancing several critical factors:

- Part Complexity & Geometry: Intricate shapes may favor RTM or compression molding, while simpler parts could use pultrusion or filament winding.

- Production Volume: Low volume (prototypes, custom parts) suits wet lay-up or manual prepreg. Medium-to-high volume benefits from RTM/VARTM, compression molding, or automated prepreg lines. High volume for constant profiles points to pultrusion.

- Required Mechanical Properties: Applications demanding the highest strength, stiffness, and minimal void content (e.g., aerospace) typically require autoclave curing of prepregs. Other methods offer varying levels of performance, often sufficient for commercial or industrial uses.

- Surface Finish Requirements: Processes like compression molding and RTM provide excellent surface finishes on both sides, critical for aesthetic or aerodynamic applications.

- Cost Implications: Tooling costs can range from low for wet lay-up to extremely high for compression molds or large autoclaves. Material costs vary (prepregs are generally more expensive than dry fiber and resin). Labor and energy consumption also contribute significantly.

- Cycle Time: Automation and rapid curing processes (e.g., compression molding, pultrusion) offer very short cycle times, essential for high-volume production.

Typical Costs Associated with Manufacturing Carbon Fiber Parts

The cost of carbon fiber parts is a complex interplay of raw materials, tooling, labor, and process efficiency. While specific figures vary wildly based on part geometry, volume, and material type, some general observations can be made:

- Raw Materials: Carbon fiber itself is a significant cost. Prepregs, offering consistency and ease of use, are typically more expensive than purchasing dry fiber and separate resin systems. According to market analysis, carbon fiber pricing can range from $20-100+/kg depending on grade and volume.

- Tooling: This is often the highest upfront cost. Autoclave molds or compression molds made from invar or steel can cost hundreds of thousands to millions of dollars. Wet lay-up molds, often made from composites or wood, are significantly cheaper.

- Labor: Manual processes like wet lay-up or hand prepreg lay-up are labor-intensive, increasing per-part cost for low-volume production. Automated processes reduce labor cost per part.

- Energy: Autoclave curing is energy-intensive due to high heat and pressure requirements.

- Post-processing: Trimming, machining, drilling, and painting add to the final cost.

For high-volume production, processes like pultrusion or compression molding can drive down per-part costs significantly (e.g., below $5-$10/kg for simple profiles in very high volumes), while low-volume, complex aerospace-grade parts can easily exceed $1000+/kg.

Common Challenges in Carbon Fiber Part Production and Solutions

Manufacturing carbon fiber parts is intricate and can present several challenges:

- Voids and Porosity: Air bubbles trapped within the laminate, reducing mechanical properties.

- Solutions: Meticulous vacuum bagging, sufficient vacuum pressure, proper debulking steps, controlled resin flow, and optimized curing cycles (especially in autoclaves).

- Resin-Rich/Starved Areas: Uneven distribution of resin, leading to brittle (resin-rich) or weak (resin-starved) spots.

- Solutions: Precise resin-to-fiber ratio control (prepregs excel here), optimized resin viscosity, controlled injection rates in RTM/VARTM, and uniform pressure in compression molding.

- Delamination: Separation of composite layers, often due to poor adhesion, excessive stress, or trapped volatiles.

- Solutions: Proper surface preparation, controlled cure temperatures and pressures, avoiding excessive thermal gradients, and careful handling.

- Dimensional Instability/Warpage: Parts distorting during or after curing due to thermal expansion mismatch between fiber and resin, or uneven cooling.

- Solutions: Optimized mold design, symmetric laminate stack-up, controlled cooling rates, and post-cure treatments.

- Material Waste: Expensive raw materials can be wasted during cutting, trimming, or due to defects.

- Solutions: Nesting optimization software for cutting patterns, recycling initiatives for carbon fiber scrap (emerging), and robust process control to minimize defects.

Essential Quality Control Measures for Carbon Fiber Components

Ensuring the quality and reliability of carbon fiber parts is paramount. Rigorous quality control (QC) is applied at every stage:

- Incoming Material Inspection: Verifying raw material (fiber, resin, prepreg) specifications, shelf life, and storage conditions.

- In-Process Monitoring: Real-time monitoring of vacuum levels, temperature profiles, pressure, and resin flow during lay-up, infusion, or molding to ensure process parameters are met.

- Non-Destructive Testing (NDT): These methods evaluate internal integrity without damaging the part:

- Ultrasonic Inspection: Uses sound waves to detect internal flaws like voids, delaminations, and foreign inclusions. Widely used for critical aerospace components.

- X-ray / Computed Tomography (CT) Scanning: Provides detailed internal images, useful for detecting voids, fiber misalignment, and complex internal structures.

- Thermography: Detects defects by observing temperature variations on the surface, often caused by internal flaws acting as heat sinks or sources.

- Visual Inspection: Essential for identifying surface defects such as scratches, resin runs, dry spots, or fiber misalignment.

- Destructive Testing: Samples or sacrificial parts are tested to failure to determine actual mechanical properties:

- Tensile, Compression, Shear, Flexural Strength Tests: Measure the material's response to various loading conditions.

- Interlaminar Shear Strength (ILSS): Measures the bonding strength between layers.

- Dimensional Inspection: Using tools like Coordinate Measuring Machines (CMMs) or 3D laser scanners to verify part dimensions, tolerances, and geometric accuracy.

By understanding these processes, challenges, and quality control measures, procurement professionals can make well-informed decisions that lead to high-quality, cost-effective carbon fiber parts, driving innovation and performance in their respective industries.

Carbon Fiber Hoods: Your Ultimate Guide to Performance, Aesthetics, and Value

The Advantages of Carbon Fiber Materials—Insights from Industry Experts

How to Choose High-Performance Carbon Fiber Materials: Supreem Carbon’s Expert Guide

Carbon Fiber Helmet produced by Supreem Carbon.

Unveiling Carbon Fiber: 10 Surprising Truths and How It's Shaping Our Future

Ducati monster 937 and BM S1000RR 2016+ new arrivals released!

For After-sales Service

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

For Facotry

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

For Carbon Fiber Material

What are the advantages of carbon fiber?

High Strength-to-Weight Ratio

It is stronger than many traditional materials, such as steel and aluminum.This high strength-to-weight ratio allows for the creation of lightweight components that maintain structural integrity and durability.

Lightweight

One of the most significant advantages of carbon fiber is its low density, contributing to lightweight structures. This property is particularly crucial in industries where weight reduction is a priority, such as aerospace, automotive, and sports equipment.

Resistant to corrosion and chemicals

Carbon fiber is inherently resistant to corrosion, making it an ideal material for applications exposed to harsh environments or corrosive substances. This property contributes to the longevity of components and reduces maintenance requirements. Carbon fiber has good chemical resistance, making it suitable for use in environments where exposure to chemicals or harsh solvents is a concern. This resistance enhances the material's durability in various industrial settings.

Tolerant of high temperature

Carbon fiber exhibits excellent thermal stability and resistance to high temperatures. This makes it suitable for applications where components are exposed to elevated temperatures, such as in the aerospace and automotive industries.

Low thermal expansion

Carbon fiber has a low coefficient of thermal expansion, meaning it expands or contracts minimally with changes in temperature. This property contributes to dimensional stability, making carbon fiber components reliable in varying temperature conditions.

Aesthetic Appeal

Carbon fiber has a modern and high-tech appearance, contributing to its aesthetic appeal. This property is leveraged in consumer goods, automotive components, and sporting equipment where visual appeal is important.

For Products

Are you parts have UV protected?

Absolutely! We use multiple layers of premium quality automotive clear (or matt) coats on our products, which ensure that they will remain super pretty for years to come.

Chevrolet Corvette C8 Carbon Fiber Engine Cover Replacement

Aprilia Tuono V4 Carbon Fiber Exhaust Cover

Aprilia Tuono V4 Carbon Fiber Front Fairing with Windshield

BMW S1000RR Carbon Fiber Lower Side Fairings Custom

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram