is carbon fiber a metal | Supreem Carbon Expert Guide

- Is Carbon Fiber a Metal?

- What Are the Key Mechanical Properties of Carbon Fiber Compared to Metals?

- How Do Carbon Fiber Parts Perform in Corrosive Environments?

- What Should Buyers Know About the Manufacturing Variability of Carbon Fiber Parts?

- Are Carbon Fiber Parts Cost-Effective Compared to Metal Parts?

- What Are the Best Practices for Procuring Carbon Fiber Parts?

Is Carbon Fiber a Metal?

Carbon fiber is often misunderstood in terms of its material classification. To clarify, carbon fiber is not a metal; it is a composite material made of thin, strong crystalline filaments of carbon that are woven and set into a resin matrix. Unlike metals, carbon fiber is non-metallic and offers high strength-to-weight ratios, corrosion resistance, and excellent fatigue properties. This unique combination makes it popular across aerospace, automotive, and sporting goods industries.

What Are the Key Mechanical Properties of Carbon Fiber Compared to Metals?

Carbon fiber composites boast a tensile strength of around 3,500 MPa, which can be up to five times stronger than some steel alloys. In addition, its density is approximately 1.6 g/cm³, significantly lighter than steel (7.85 g/cm³) or aluminum (2.7 g/cm³). This lightweight characteristic aids in weight reduction efforts in industries such as aerospace and automotive manufacturing, where performance and efficiency are critical.

How Do Carbon Fiber Parts Perform in Corrosive Environments?

Unlike metals, carbon fiber does not readily corrode or rust, although the epoxy resin matrix can degrade under UV exposure or chemical attack if not properly treated. This resistance to corrosion makes carbon fiber parts highly desirable in marine, chemical, and outdoor applications where metal parts would require additional protective coatings.

What Should Buyers Know About the Manufacturing Variability of Carbon Fiber Parts?

The quality and performance of carbon fiber parts highly depend on the layup process, resin type, fiber orientation, and curing process. Variations in these factors can lead to differences in strength, flexibility, and durability. Therefore, buyers should request detailed manufacturing specifications and certifications such as ASTM D3039 for tensile properties or ISO 9001 for quality management. Partnering with reputable suppliers ensures consistent performance.

Are Carbon Fiber Parts Cost-Effective Compared to Metal Parts?

While the raw materials and manufacturing processes for carbon fiber are generally more expensive than metals, the overall cost-efficiency comes from enhanced performance, fuel savings due to lower weight, and longer service life in corrosive environments. For high-performance applications, the higher upfront investment can result in lower total cost of ownership.

What Are the Best Practices for Procuring Carbon Fiber Parts?

Procurement professionals should verify material certifications, request samples for testing, and review supplier manufacturing processes to ensure parts meet design requirements. Understanding the end-use environment and mechanical load conditions is essential when selecting carbon fiber grades and resin types. Additionally, inquire about post-manufacture treatment and warranty conditions to safeguard against premature failure.

The 5 Questions You've Always Had About Carbon Fiber

Carbon Fiber Helmet produced by Supreem Carbon.

100% Carbon fiber dash panel and window door trims set for NSX

Supreem Carbon New arrivals alert!

Understanding the Difference Between Dry Carbon and Wet Carbon Products

New arrivals of Honda CBR1000RR-R!

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

For Order Delivery

What is the shipping time for the different ways?

Express delivery 5-7 days.

20-25 days by sea.

15 days by air.

How to choose the mode of transportation?

We use official shipment like Fedex,UPS,DHL and so on. Also customer can arrange delivery by themselves.

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

Honda CBR1000RR-R Carbon Fiber Tank Side Panels

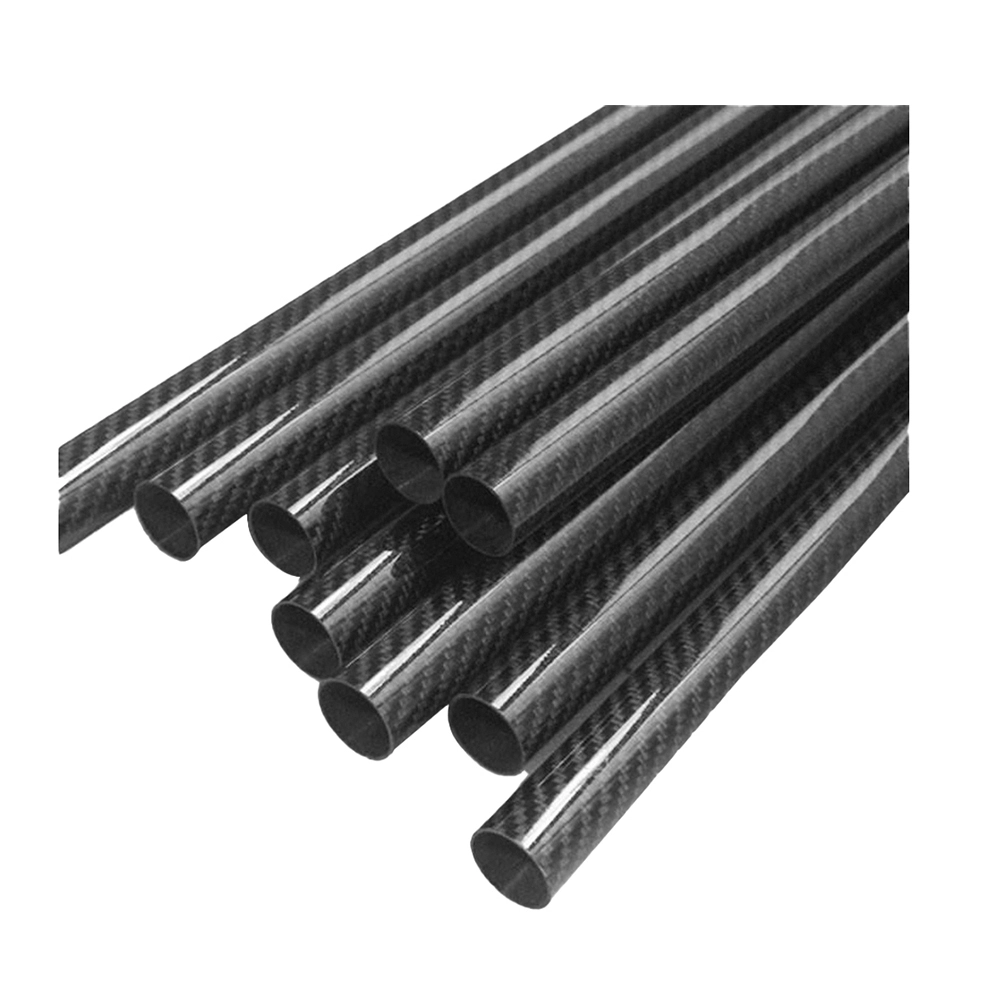

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Honda CBR1000RR-R Carbon Fiber Side Fairing

Ducati Monster 937 Carbon Fiber Chain Guard

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram