What causes carbon fiber delamination in manufacturing and use? | Insights by Supreem Carbon

- 1. What is Carbon Fiber Delamination?

- 2. What Are the Primary Causes of Carbon Fiber Delamination?

- 3. How Does Delamination Affect the Performance of Carbon Fiber Parts?

- 4. What Are the Methods to Prevent Carbon Fiber Delamination?

- 5. How Can Delamination Be Detected in Carbon Fiber Parts?

- 6. What Are the Repair Options for Delaminated Carbon Fiber Parts?

- Supreem Carbon's Advantages in Addressing Delamination

- Data Sources

1. What is Carbon Fiber Delamination?

Carbon fiber delamination refers to the separation between layers in a composite material, compromising its structural integrity. This phenomenon can occur during manufacturing or in-service conditions, leading to reduced performance and potential failure of the component.

2. What Are the Primary Causes of Carbon Fiber Delamination?

Delamination in carbon fiber composites can result from several factors:

- Manufacturing Defects: Inadequate bonding during the lay-up process, improper curing temperatures, or insufficient resin application can lead to weak interfaces between layers, making them susceptible to separation under stress.

- Impact Damage: External forces, such as impacts from debris or collisions, can cause localized damage, initiating delamination that may not be immediately visible on the surface.

- Environmental Factors: Exposure to moisture, temperature fluctuations, or UV radiation can degrade the resin matrix, weakening the bond between fibers and increasing the risk of delamination over time.

- Manufacturing Process Variability: Variations in the manufacturing process, such as inconsistent fiber orientation or resin distribution, can create internal stresses that lead to delamination.

3. How Does Delamination Affect the Performance of Carbon Fiber Parts?

Delamination can significantly impact the mechanical properties of carbon fiber components:

- Reduced Strength and Stiffness: The separation between layers diminishes the load-bearing capacity and rigidity of the part, potentially leading to premature failure under operational loads.

- Increased Weight: Delaminated areas may require additional material or reinforcement to restore structural integrity, adding unnecessary weight to the component.

- Compromised Safety: In critical applications, such as aerospace or automotive industries, delamination can pose serious safety risks due to unexpected component failure.

4. What Are the Methods to Prevent Carbon Fiber Delamination?

Implementing effective strategies during manufacturing and maintenance can mitigate the risk of delamination:

- Optimized Manufacturing Techniques: Employing advanced methods like Tailored Fiber Placement (TFP) allows for precise fiber orientation and material placement, reducing internal stresses and enhancing the composite's resistance to delamination. TFP enables the creation of complex geometries with minimal waste, improving both performance and cost-effectiveness.

- Use of Reinforcement Methods: Incorporating techniques such as Z-pinning, where reinforcing fibers are inserted perpendicular to the composite layers, can significantly improve resistance to delamination. Z-pinning enhances the interlaminar shear strength, preventing the separation of layers under stress.

- Environmental Protection: Applying protective coatings or using ceramic matrix composites can shield carbon fiber components from environmental degradation, thereby reducing the likelihood of delamination. Ceramic matrix composites, for instance, offer enhanced thermal and oxidation resistance, extending the service life of carbon fiber parts.

5. How Can Delamination Be Detected in Carbon Fiber Parts?

Early detection of delamination is crucial for maintaining the integrity of carbon fiber components:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, infrared thermography, and X-ray imaging can identify internal delamination without damaging the part. These methods detect variations in material properties indicative of delamination.

- Visual Inspection: Regular visual checks for signs like surface bulging, cracks, or unusual wear patterns can provide early indications of delamination.

6. What Are the Repair Options for Delaminated Carbon Fiber Parts?

Addressing delamination promptly can restore the functionality of carbon fiber components:

- Surface Repairs: Minor delamination can often be repaired by sanding the affected area, applying resin, and re-laminating with new carbon fiber layers.

- Structural Repairs: For significant delamination, professional repair services may be required, involving techniques like vacuum bagging and autoclave curing to ensure proper bonding and restore strength. ((https://www.supreemcarbon.com/repair-maintain-custom-carbon-fiber-parts.html?utm_source=openai))

Supreem Carbon's Advantages in Addressing Delamination

Supreem Carbon offers comprehensive solutions to combat delamination in carbon fiber components:

- Advanced Manufacturing Techniques: Utilizing state-of-the-art methods to ensure optimal fiber orientation and resin application, minimizing the risk of delamination from the outset.

- Expert Repair Services: Providing professional repair services equipped with the latest NDT technologies to accurately assess and address delamination issues, restoring component integrity effectively.

- Customized Solutions: Offering tailored solutions to meet specific client needs, ensuring enhanced performance and longevity of carbon fiber parts.

Data Sources

- Wikipedia: Tailored Fiber Placement. Accessed November 2025.

- Wikipedia: Z-pinning. Accessed November 2025.

- Wikipedia: Ceramic Matrix Composite. Accessed November 2025.

- Wikipedia: Carbon Fiber. Accessed November 2025.

- Wikipedia: Delamination. Accessed November 2025.

- Supreem Carbon: Repairing & Maintaining Custom Carbon Fiber Parts. Accessed November 2025.

Unveiling Carbon Fiber: 10 Surprising Truths and How It's Shaping Our Future

Supreem Carbon Cross-Country Mountain Bike Seat: The Ultimate Lightweight Carbon Fiber Upgrade

Supreem Carbon new engine cover released!

Latest Developments in the Application of Carbon Fiber Materials in the Automotive and Motorcycle Fields

Carbon Fiber in Everyday Products: Modern Applications & Home Uses | Supreem Carbon

2020+ Toyota Supra A90 Carbon Fiber Engine Cover released!

For Customized Service

What is the customization process of carbon fiber products?

1. Customer provide 3D drawing, design requirement or idea

2. Technician evaluate project feasibility and provide a quotation

3. Project confirmation and arrange sample production

4. Delivery and customer feedback

5. Big scale orders production

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

For After-sales Service

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

For Facotry

How many monthly production capacity of the factory?

The average monthly production capacity reach 3000 pieces. With the equipment upgrade, it will be increased over 4000 pieces per month.

BMW S1000RR Carbon Fiber Front Fairing Cowls Custom

Kawasaki H2/H2R Carbon Fiber Tail Center Fairing

Kawasaki Z900 Z900RS Carbon Fiber Rear Fender

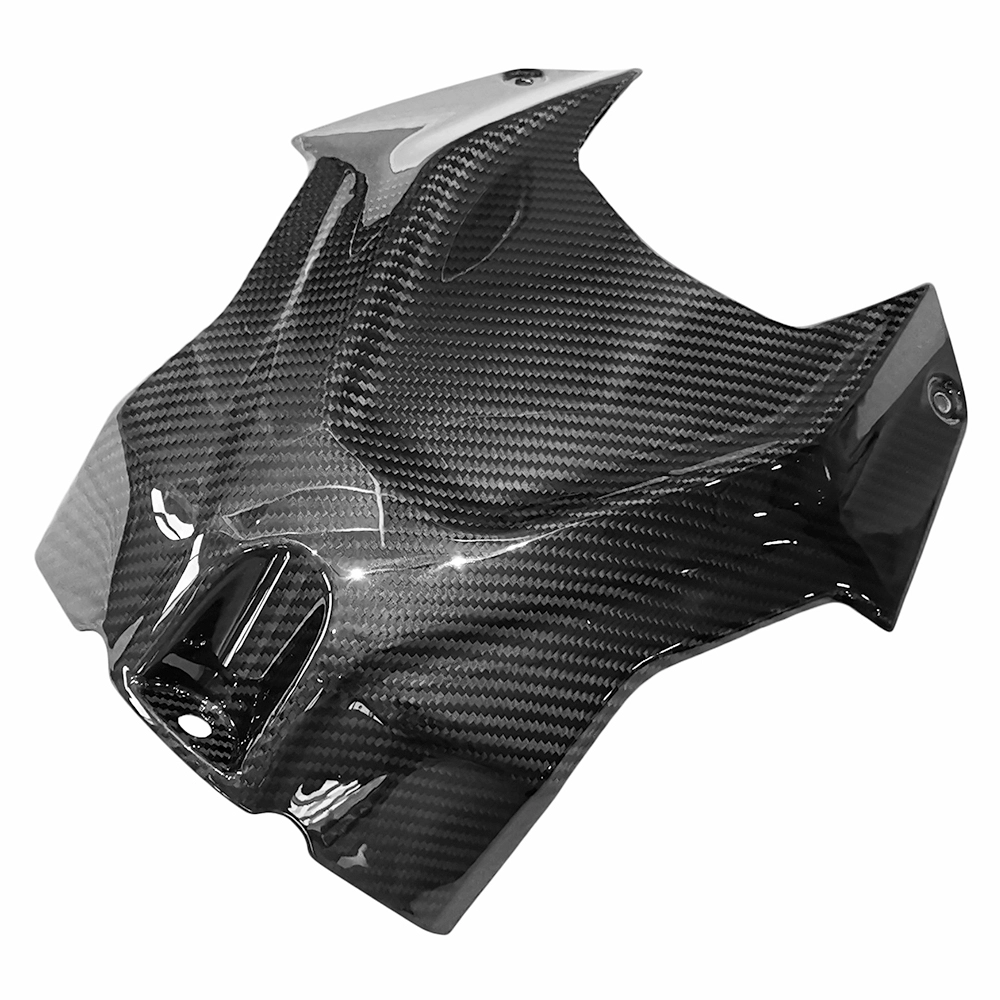

BMW S1000RR S1000R Carbon Fiber Tank Airbox Cover

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram