How do manufacturing methods affect carbon fiber prices?

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred material in industries such as aerospace, automotive, and sports equipment. However, its high cost often raises questions among procurement professionals. This article delves into the primary factors contributing to the expense of carbon fiber and offers insights for informed purchasing decisions.

1. What are the primary factors contributing to the high cost of carbon fiber?

The high cost of carbon fiber can be attributed to several key factors:

Raw Material Expenses: The production of carbon fiber begins with the acquisition of precursor materials, primarily polyacrylonitrile (PAN). PAN is derived from petroleum-based sources, and its extraction and processing are energy-intensive, contributing significantly to the overall cost.

Energy-Intensive Manufacturing Process: Converting PAN into carbon fiber involves multiple stages, including oxidation, carbonization, and surface treatment. These processes require precise temperature control and substantial energy consumption, further elevating production costs.

Labor and Equipment Costs: The manufacturing of carbon fiber components often involves specialized equipment such as autoclaves and requires skilled labor for tasks like layup and curing. The need for manual intervention in many cases adds to the labor costs.

Limited Economies of Scale: Compared to metals, carbon fiber production is still relatively niche, leading to higher per-unit costs due to limited mass production capabilities.

2. How do manufacturing methods affect carbon fiber prices?

Manufacturing methods play a crucial role in determining the cost of carbon fiber products:

Prepreg Layup Process: This method involves layering pre-impregnated carbon fiber sheets in a mold, which are then cured under heat and pressure. While it offers high-quality results, the process is labor-intensive and requires specialized equipment, contributing to higher costs.

Wet Layup Process: A more cost-effective alternative, the wet layup process involves manually applying resin to dry carbon fiber sheets. This method is less labor-intensive and does not require specialized equipment, making it suitable for lower-cost applications. ((https://www.supreemcarbon.com/article/why-is-carbon-fiber-so-expensive.html))

Automated Fiber Placement (AFP): This advanced technique uses robotic systems to place carbon fiber tapes precisely, reducing labor costs and improving consistency. However, the initial investment in AFP technology is substantial, which can increase the overall cost of production.

3. How does the choice of resin impact the cost of carbon fiber components?

The type of resin used in carbon fiber composites significantly affects both performance and cost:

Epoxy Resins: Offering superior mechanical properties and thermal stability, epoxy resins are commonly used in high-performance applications. However, they are more expensive due to their enhanced properties.

Vinyl Ester Resins: Providing a balance between performance and cost, vinyl ester resins are used in applications where high performance is not critical, offering a more economical option.

Polyester Resins: The most cost-effective resin, polyester resins are used in applications where performance requirements are lower, such as in some consumer products.

4. What role does market demand play in the pricing of carbon fiber?

Market demand significantly influences carbon fiber prices:

High-Demand Industries: Sectors like aerospace and automotive, which require high-performance carbon fiber components, drive up demand and, consequently, prices.

Emerging Applications: The expansion of carbon fiber use into industries such as wind energy and consumer electronics increases overall demand, potentially leading to higher prices.

5. Are there strategies to reduce the cost of carbon fiber components without compromising quality?

Procurement professionals can consider the following strategies to optimize costs:

Specify Performance Goals: Clearly define performance requirements (e.g., stiffness, weight, impact resistance) to allow suppliers to recommend cost-effective material and manufacturing solutions. ((https://www.supreemcarbon.com/article/why-is-carbon-fiber-so-expensive.html))

Consider Hybrid Designs: Utilize hybrid structures that combine carbon fiber with other materials like aluminum or thermoplastics to achieve desired performance at a reduced cost.

Increase Order Quantities: Larger order volumes can help amortize tooling and setup costs, leading to lower per-unit prices.

Collaborate with Suppliers Early: Engage suppliers in the design phase to receive feedback on manufacturability and potential cost-saving opportunities.

Conclusion

Understanding the multifaceted factors that contribute to the high cost of carbon fiber is essential for making informed procurement decisions. By considering raw material expenses, manufacturing complexities, and market dynamics, and by implementing strategic approaches, organizations can effectively manage costs while leveraging the benefits of carbon fiber in their products.

About Supreem Carbon

Supreem Carbon specializes in providing high-quality carbon fiber components tailored to meet specific performance and budget requirements. With a focus on innovation and customer satisfaction, Supreem Carbon offers cost-effective solutions without compromising on quality.

Supreem Carbon new engine cover released!

Custom Xiaomi SU7 Carbon Fiber Parts – Supreem Carbon

Fabricante de fibra de carbono para motocicletas de alta calidad de China

New Arrivals of BMW S1000RR 2020+ full carbon fiber sets.

Analysis of Delamination Problems in Carbon Fiber Products and How to Avoid it

Great News!!! Ducati V4 SP new arrivals released.

For After-sales Service

Do you offer the fitting advice?

Of course! If you have any questions, please contact us on info@supreemcarbon.com.

Do you offer a warranty?

Six month standard warranty on all products. Damage due to installation error or natural elements will not be covered.

For Products

Which carbon fiber material you can provide in production?

1*1 plain /2*2 twill / forged carbon / honeycomb / kevlar and so on.

Are you parts have UV protected?

Absolutely! We use multiple layers of premium quality automotive clear (or matt) coats on our products, which ensure that they will remain super pretty for years to come.

For Facotry

When is Supreem carbon founded?

Our company formally established in early 2017.

Aprilia Tuono V4 Carbon Fiber Chain Guard

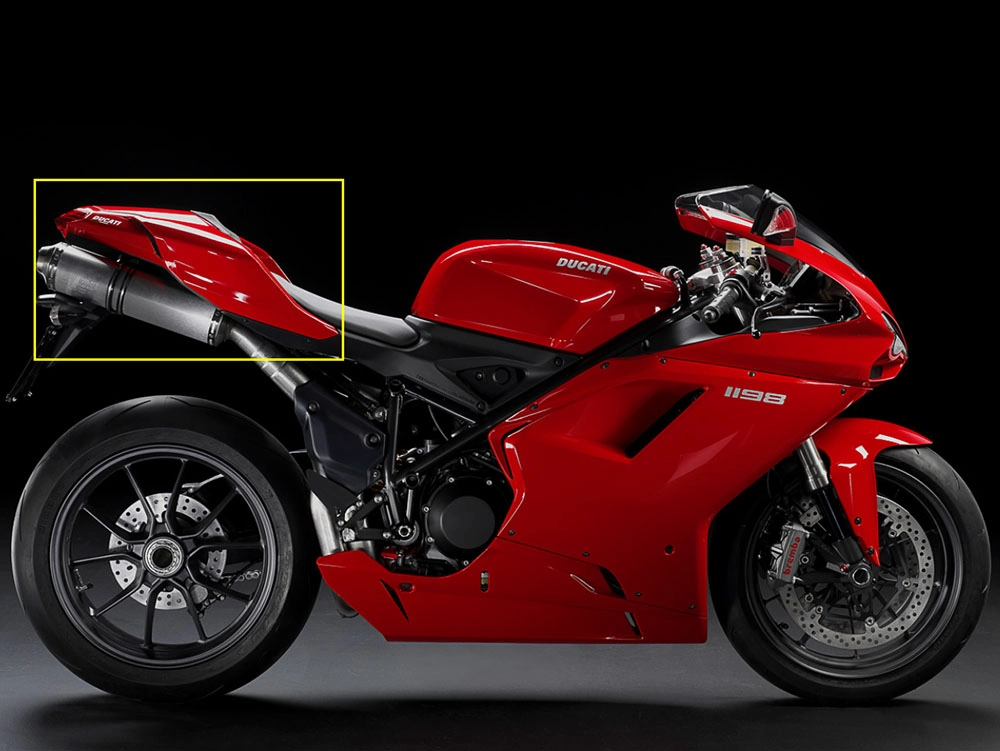

Kawasaki ZX10R Carbon Fiber Rear Tail Panel

Custom Carbon Fiber Wine Bracket

A carbon fiber wine bracket is a premium display solution engineered to combine modern aesthetics with exceptional structural performance. Manufactured from high-strength carbon fiber composite materials, it offers a lightweight yet rigid support system for securely holding and showcasing wine bottles. Its refined texture, durability, and contemporary design make it ideal for luxury retail environments, custom interior projects, and high-end hospitality applications.

Yamaha R1 R1M Carbon Fiber Front Fairing

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram