is carbon fiber worth the high price | Insights by Supreem Carbon

- 1. What Are the Key Advantages of Carbon Fiber Parts?

- 2. What Are the Disadvantages of Carbon Fiber Parts?

- 3. How Does Carbon Fiber Compare to Traditional Materials?

- 4. In Which Industries Is Carbon Fiber Most Beneficial?

- 5. How Should Procurement Professionals Approach Carbon Fiber Acquisition?

- Conclusion: The Advantages of Supreem Carbon

1. What Are the Key Advantages of Carbon Fiber Parts?

Carbon fiber parts offer several notable benefits:

Lightweight: Carbon fiber is approximately five times lighter than steel and twice as light as aluminum, making it ideal for applications where weight reduction is crucial.

High Strength-to-Weight Ratio: Despite its lightness, carbon fiber is five times stronger than steel, providing exceptional strength without adding significant weight.

Corrosion Resistance: Unlike metals, carbon fiber does not corrode, ensuring longevity and reduced maintenance costs in various environments.

Low Thermal Expansion: Carbon fiber exhibits minimal expansion or contraction with temperature changes, maintaining structural integrity in varying thermal conditions.

Design Flexibility: The material's versatility allows for complex and customized designs, enabling innovation in product development.

2. What Are the Disadvantages of Carbon Fiber Parts?

While carbon fiber offers numerous advantages, there are notable drawbacks to consider:

High Cost: The manufacturing process of carbon fiber is complex and energy-intensive, leading to higher production costs compared to traditional materials.

Brittleness: Carbon fiber is less ductile than metals, making it susceptible to cracking under impact or stress, which can complicate repairs.

Repair Challenges: Damaged carbon fiber components often require complete replacement, as repairs can be difficult and costly.

Electrical Conductivity: Carbon fiber conducts electricity, which may pose risks in certain applications where electrical insulation is necessary.

3. How Does Carbon Fiber Compare to Traditional Materials?

When evaluating carbon fiber against traditional materials like steel and aluminum:

Weight and Performance: Carbon fiber's lighter weight contributes to improved fuel efficiency and performance in vehicles, as lighter vehicles consume less fuel.

Strength and Durability: Carbon fiber's high tensile strength and resistance to corrosion offer advantages over metals, leading to longer-lasting components.

Cost Considerations: The higher cost of carbon fiber may be offset by its performance benefits, but this depends on the specific application and budget constraints.

4. In Which Industries Is Carbon Fiber Most Beneficial?

Carbon fiber is particularly advantageous in industries where performance and weight are critical:

Aerospace: The aviation sector utilizes carbon fiber for its lightweight and strength properties, enhancing fuel efficiency and performance.

Automotive: High-performance vehicles and racing cars employ carbon fiber to reduce weight and improve speed and handling.

Sports Equipment: Items like bicycles, fishing rods, and sporting goods benefit from carbon fiber's strength and lightness, enhancing performance.

5. How Should Procurement Professionals Approach Carbon Fiber Acquisition?

When considering the procurement of carbon fiber parts:

Cost-Benefit Analysis: Evaluate whether the performance and durability benefits justify the higher initial investment.

Supplier Evaluation: Assess suppliers' capabilities, quality control measures, and reputation to ensure reliable and high-quality products.

Lifecycle Considerations: Consider the total cost of ownership, including maintenance, repair, and potential replacement costs.

Application Suitability: Ensure that carbon fiber is appropriate for the specific application, considering factors like impact resistance and environmental conditions.

Conclusion: The Advantages of Supreem Carbon

Supreem Carbon offers several advantages for procurement professionals seeking high-quality carbon fiber parts:

Rich Experience: With over 10 years in the carbon fiber industry, Supreem Carbon provides customers with high-quality products. ((https://www.supreemcarbon.com/article/disadvantages-of-carbon-fiber-in-cars-a-buyer-s-guide.html))

Excellent Service: From new project development to product delivery, Supreem Carbon offers full tracking and timely feedback on project progress. ((https://www.supreemcarbon.com/article/disadvantages-of-carbon-fiber-in-cars-a-buyer-s-guide.html))

High-Quality Products: Supreem Carbon's products undergo rigorous quality control to ensure customers receive high-quality and cost-effective products. ((https://www.supreemcarbon.com/article/disadvantages-of-carbon-fiber-in-cars-a-buyer-s-guide.html))

By partnering with Supreem Carbon, procurement professionals can access reliable and high-quality carbon fiber components that meet their specific needs.

References:

"Advantages & Disadvantages of Carbon Fiber," China Composites, August 29, 2016.

"Professional Carbon Fiber Component Manufacturing: Analysis of the Advantages and Disadvantages," AFI Parts, September 2025.

"Carbon Fiber Composites: Properties | Manufacturing Methods | Pros and Cons," Dexcraft, November 2025.

"Disadvantages of Carbon Fiber in Cars: A Buyer's Guide," Supreem Carbon, November 2025. ((https://www.supreemcarbon.com/article/disadvantages-of-carbon-fiber-in-cars-a-buyer-s-guide.html))

"Carbon Fiber vs OEM Body Parts Pros and Cons Explained," CarbonXtreme, November 2025.

"Introduction of Carbon Fiber Material: Pros and Cons," HG Composites, November 2025.

"Pros and Cons of Carbon Fiber," Luxwisp, November 2025.

Supreem Carbon New arrivals alert!

How to Make Carbon Fiber Car Parts?

Chinese Carbon Fiber Manufacturer Brands: Supreem Carbon in the Spotlight

Carbon Fiber Composites: Applications, Benefits, and Industry Trends

New arrivals---Carbon Fiber Slam Panel Replacement for BMW M3 M4

Unveiling Carbon Fiber: 10 Surprising Truths and How It's Shaping Our Future

For Products

How can I get some sample?

Actually we dont provide the free sample to customer, you can place a sample order if need some parts.

Which surface could you provide for the carbon parts?

Gloss finish, matte finish, satin finish. Some color coating as the customer needs.

What is main products for factory?

Supreem carbon mainly produce carbon fiber custom products for automobile and motorcycle accessaries, including the design, develop and manufacturing of appearance parts, interior parts, functional parts, etc. Other carbon fiber custom goods also can produce for you.

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

What can be customized in addition to customized carbon fiber parts?

You can customize your company logo, packaging, even the color of coating and so on.

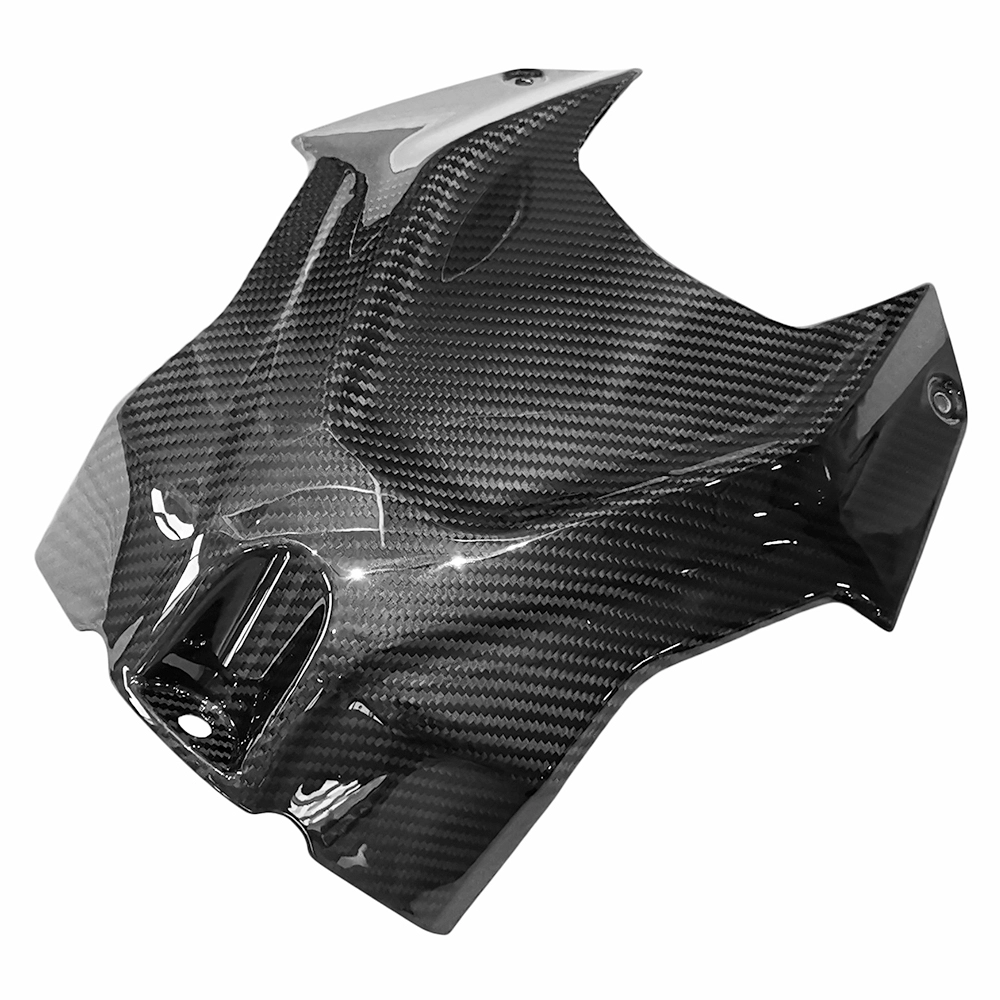

BMW S1000RR S1000R Carbon Fiber Tank Airbox Cover

BMW M2 M3 Carbon Fiber Engine Cover Replacement

Custom Carbon Fiber Wine Bracket

A carbon fiber wine bracket is a stylish and functional accessory designed to securely hold and display wine bottles.

Honda CBR1000RR-R Carbon Fiber Tank Side Panels

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram