How much strength is lost from carbon fiber delamination?

Carbon fiber composites are renowned for their high strength-to-weight ratio and are widely used in various industries, including automotive, aerospace, and sports equipment. However, one significant challenge in utilizing these materials is delamination—a separation between layers within the composite structure. Understanding the causes, effects, and preventive measures for delamination is crucial for ensuring the performance and longevity of carbon fiber components.

Delamination in carbon fiber composites can occur due to several factors, including manufacturing defects, impact damage, environmental exposure, and material incompatibilities. Manufacturing defects such as inadequate resin application, insufficient curing, or poor fiber alignment can create weak interfaces between layers, leading to delamination. Impact events, like collisions or drops, can also initiate delamination by causing localized damage. Environmental factors, including moisture, temperature fluctuations, and chemical exposure, can degrade the resin matrix, weakening the bond between layers and promoting delamination. Additionally, using incompatible materials or improper bonding techniques can increase the risk of delamination.

The presence of delamination significantly compromises the mechanical properties of carbon fiber composites. Studies have shown that delamination can lead to a reduction in compressive strength and stiffness. For instance, a study on unidirectional carbon fiber reinforced epoxy composites found that delamination areas exceeding 60 mm² resulted in a decrease in compressive strength and Young's modulus. Specifically, for every increment of 40 mm² in delamination area, the Young's modulus and compressive strength decreased by about 4.85% and 5.12%, respectively.

Preventing delamination involves several key strategies:

Optimized Manufacturing Processes: Ensure thorough surface preparation, uniform resin application, proper pressure during curing, and controlled curing conditions to promote strong interlaminar bonds.

Material Selection: Choose high-quality, compatible resins and fibers, and consider using pre-preg materials for consistent bonding.

Design Optimization: Avoid sharp corners and abrupt transitions, and strategically orient fibers to handle anticipated loads, reducing stress concentrations that can lead to delamination.

Post-Manufacturing Quality Control: Implement non-destructive testing methods like ultrasonic testing, X-ray, or thermography to detect voids or weak spots that could lead to delamination.

By understanding the causes and effects of delamination and implementing preventive measures, manufacturers can enhance the durability and performance of carbon fiber components.

Supreem Carbon specializes in producing high-quality carbon fiber products with advanced manufacturing techniques to minimize delamination risks. Their commitment to quality control and material selection ensures the reliability and longevity of their components.

For more information on delamination and its impact on carbon fiber products, visit Supreem Carbon's (https://www.supreemcarbon.com/delaminated-carbon-fiber-impact.html).

Лучший производитель углеродного волокна в Китае

How Long Does Carbon Fiber Last? Unveiling the Durability of a Tech Marvel

Supreem carbon Honda-NSX 100% Fiber Door Handle released!

Newest Acura NSX Carbon Fiber Hood Vent released!

Carbon Fiber Composites: Applications, Benefits, and Industry Trends

Unveiling Carbon Fiber: 10 Surprising Truths and How It's Shaping Our Future

For Customized Service

How long does the customized products order take?

This depends on the complexity and mold production cycle of the product. The first sample will be ready in 2-3 weeks after mold finished.

For After-sales Service

How can I cancel the order?

We may only cancel your order if it has not been fulfilled yet. We would be more than happy to assist you with any adjustments if you'd wish instead!

What can I do if the carbon fiber products arrived is broken?

Please give us feedback as soon as possible and we will send new one to you.

For Facotry

How many employees of Supreem carbon?

We have over 50 employees, including over 40 skilled workers, 3 R&D designers, and 5 QC professionals and so on.

Can I visit your company?

Of course, we are in QiaoTou Town, Dongguan City, Guangdong Province, China.

BMW S1000RR Carbon Fiber Lower Side Fairings Custom

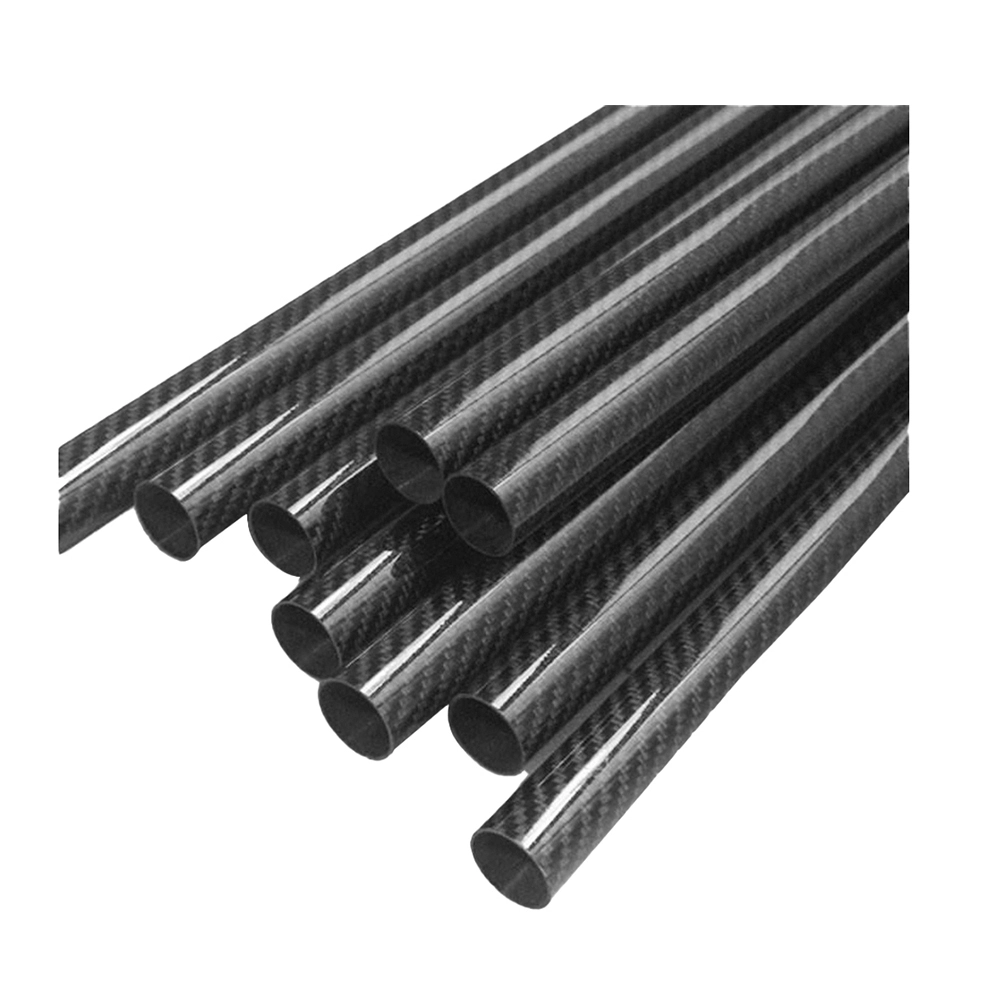

Supreem Carbon High-Quality Custom Carbon Fiber Sheets and Tubes

Carbon fiber tubes and sheets are widely used across industries thanks to their exceptional strength, lightweight construction, and versatile performance. These materials enable high-precision, durable, and innovative solutions for automotive, aerospace, industrial, and consumer applications.

Honda CBR1000RR-R Carbon Fiber Side Fairing

Yamaha R1 Carbon Fiber Airbox Tank Cover

The Supreem Carbon Yamaha R1 Carbon Fiber Airbox Tank Cover provides lightweight, durable protection with a sleek finish. Designed for R1 models, it enhances the style and performance of your bike. Its lightweight structure improves performance while maintaining the premium aesthetics necessary for high-end modification projects. As a dedicated manufacturer of carbon fiber parts, we provide stable production capacity, customization options, and strict quality control to support enterprise-level procurement and OEM/ODM needs.

Let’s Bring Your Carbon Fiber Ideas to Life

Have a question or inquiry about our carbon fiber composite products? Leave us a message here, and our team will get back to you promptly.

Whether you're interested in custom orders, technical specifications, or partnership opportunities, we're here to assist you.

Please fill out the fields above with your name, email address, and message.

© 2024 Supreem Carbon All Rights Reserved.

Facebook

Pinterest

LinkedIn

Instagram